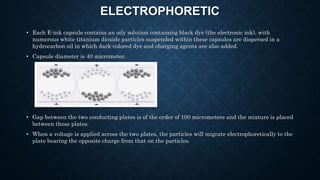

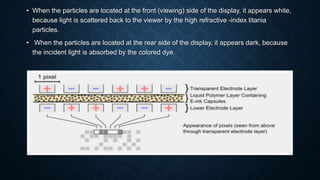

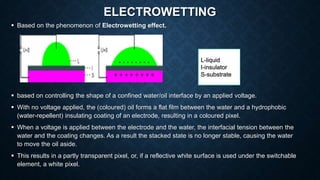

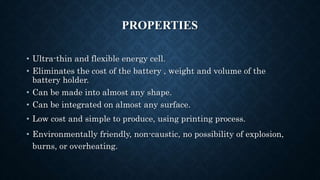

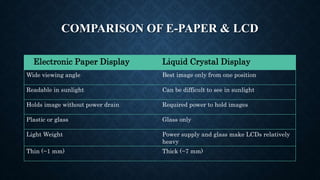

The document discusses e-paper technology, detailing its construction, working technologies, and historical context from its conception in the 1970s to its commercial release by Sony in 2004. It examines the properties, advantages, disadvantages, and applications of e-paper compared to LCD displays, highlighting its low power consumption and flexibility. The future of e-paper is suggested to lead to a paperless world with affordable, versatile digital reading devices accessible globally.