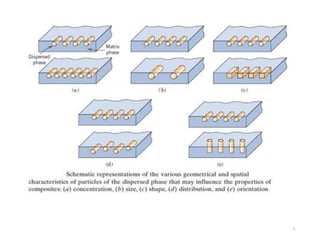

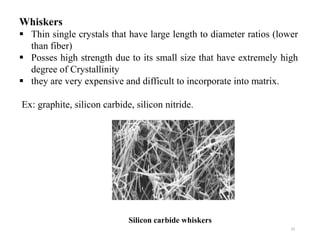

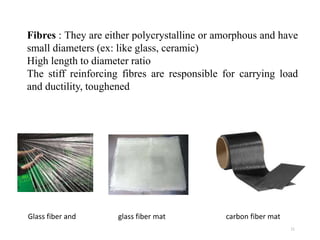

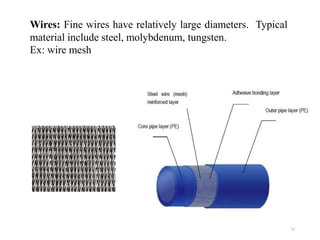

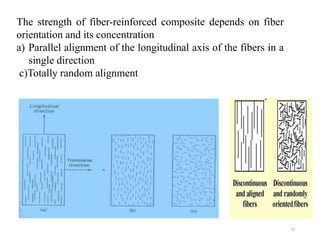

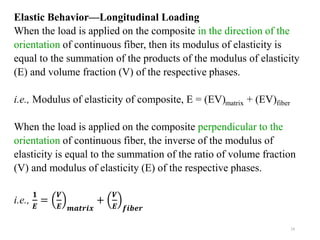

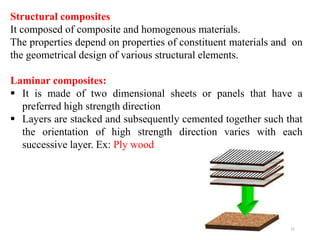

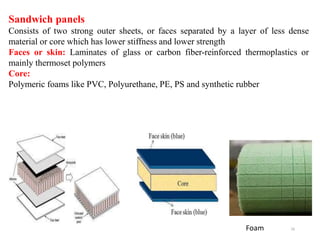

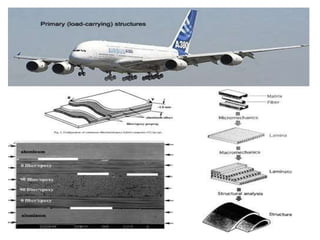

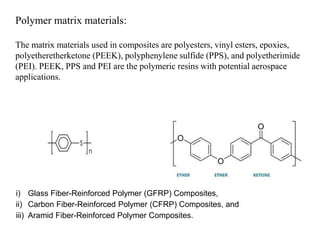

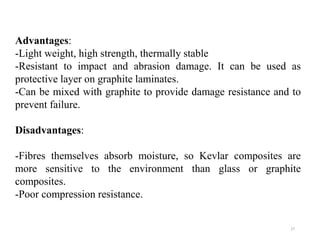

This document discusses different types of composite materials. It defines a composite as containing two or more distinct materials. Composites contain a matrix phase that surrounds and binds the dispersed reinforcing phase. The document describes different types of matrices (metal, polymer, ceramic) and reinforcing phases (fibers, particles, whiskers). It classifies composites as particle-reinforced, fiber-reinforced, or structural based on the reinforcing phase. For each type, it provides examples, properties, and applications. The key advantages of polymer composites are also summarized.