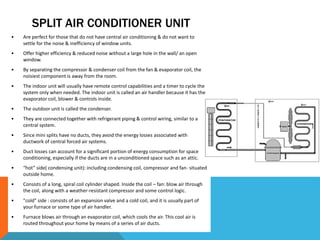

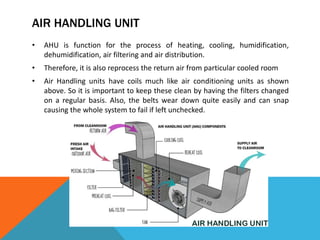

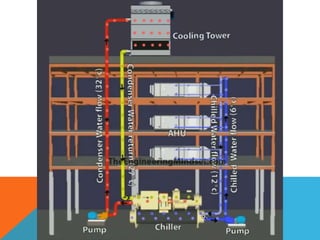

The document discusses heating, ventilation, and air conditioning (HVAC) systems and indoor air quality. It describes how HVAC systems work and the components involved, including the refrigeration cycle, air handling units, ducting, and different system types like window units, split units, and central air conditioning. It also discusses factors that affect indoor air quality like temperature, humidity, airflow, and maintenance of HVAC equipment. Poor indoor air quality can cause health issues and impact productivity.