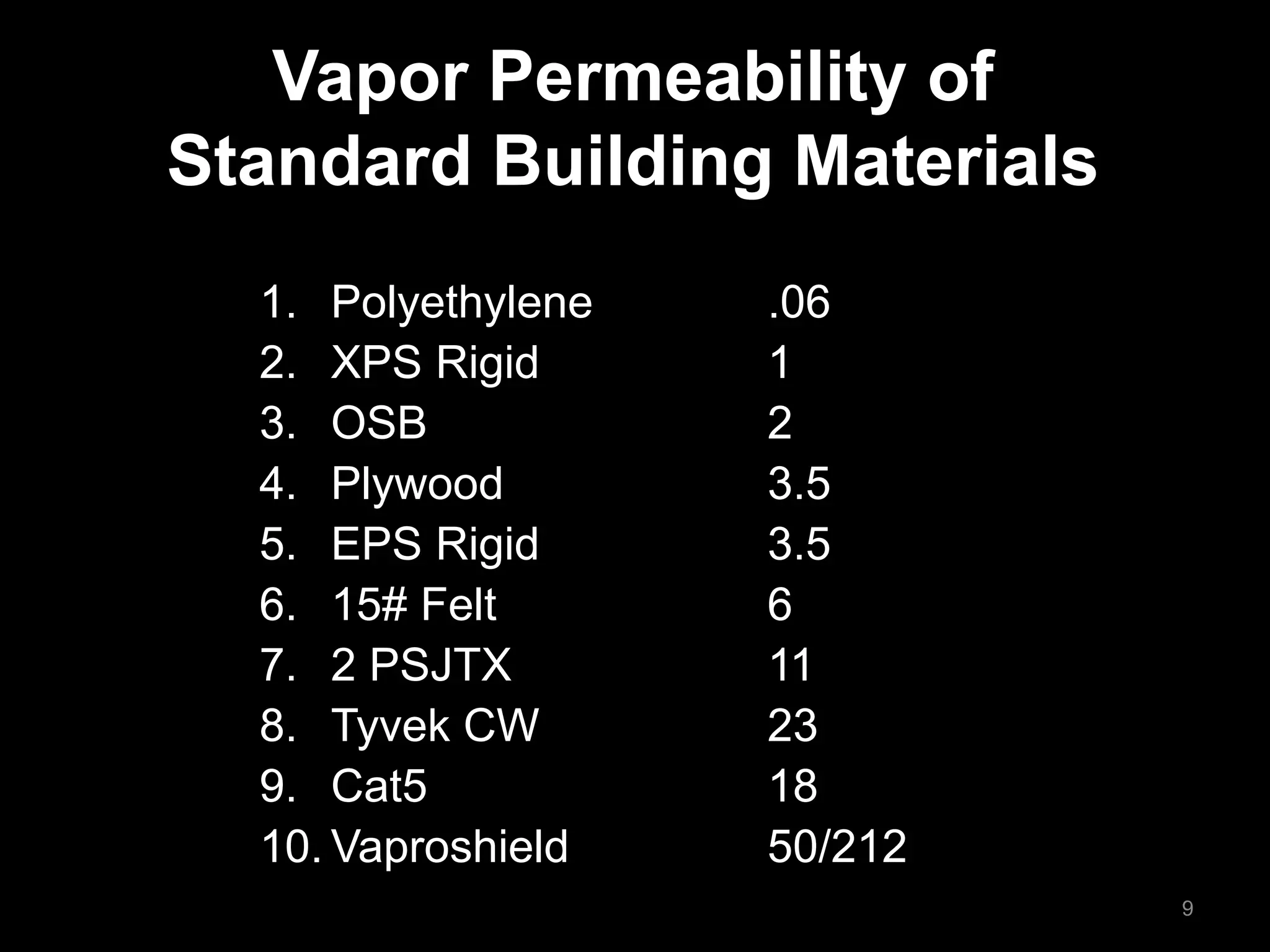

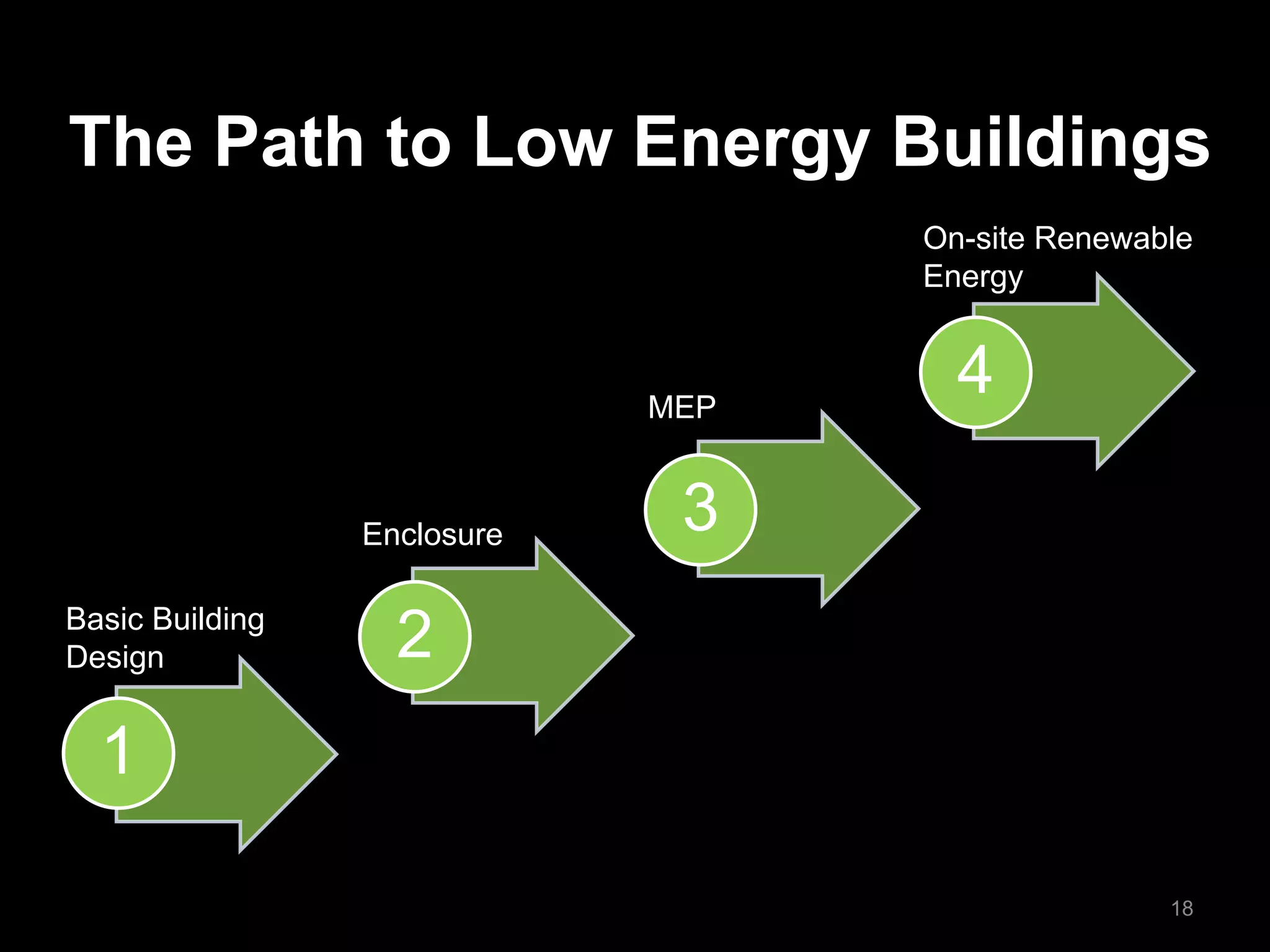

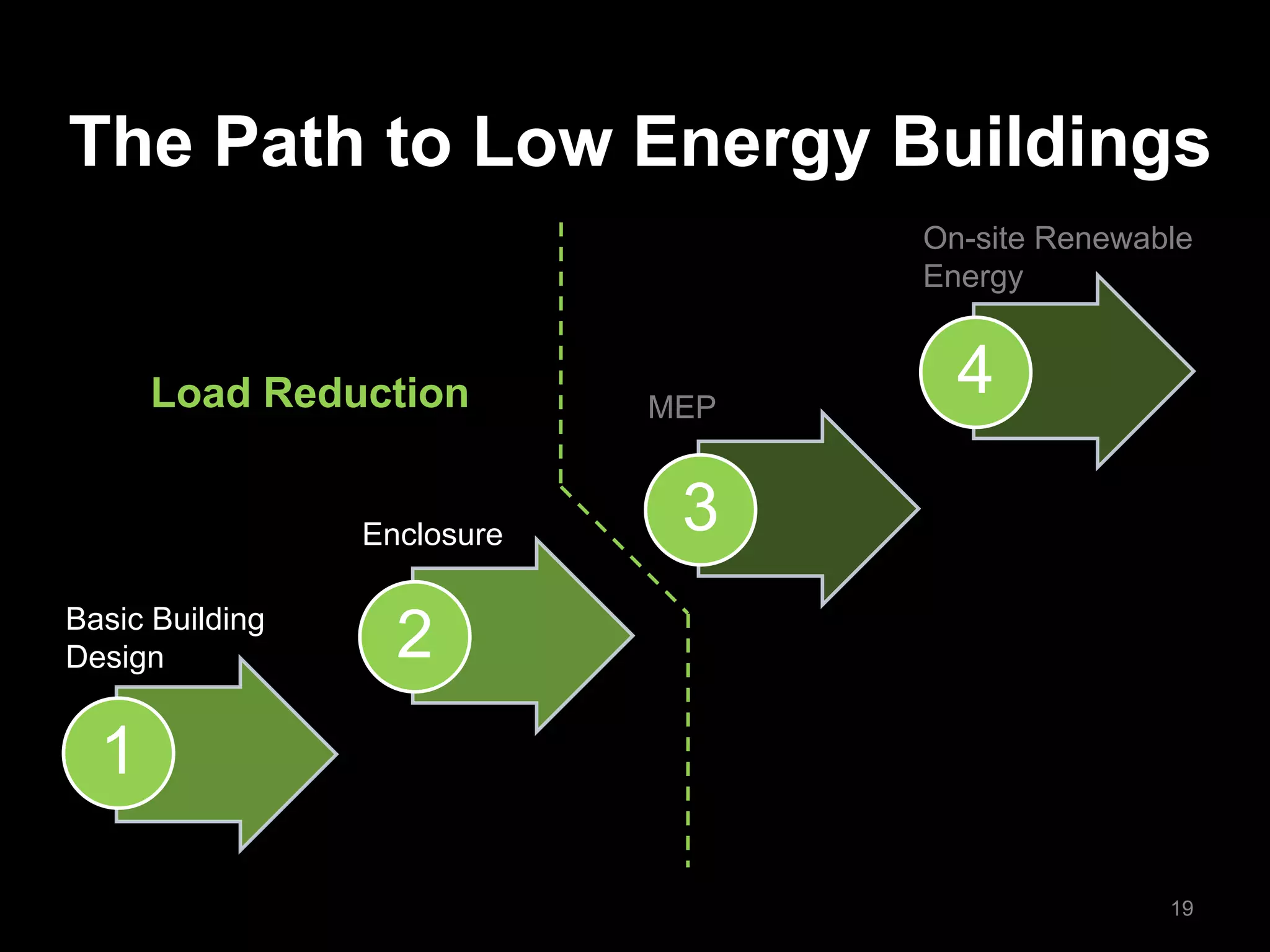

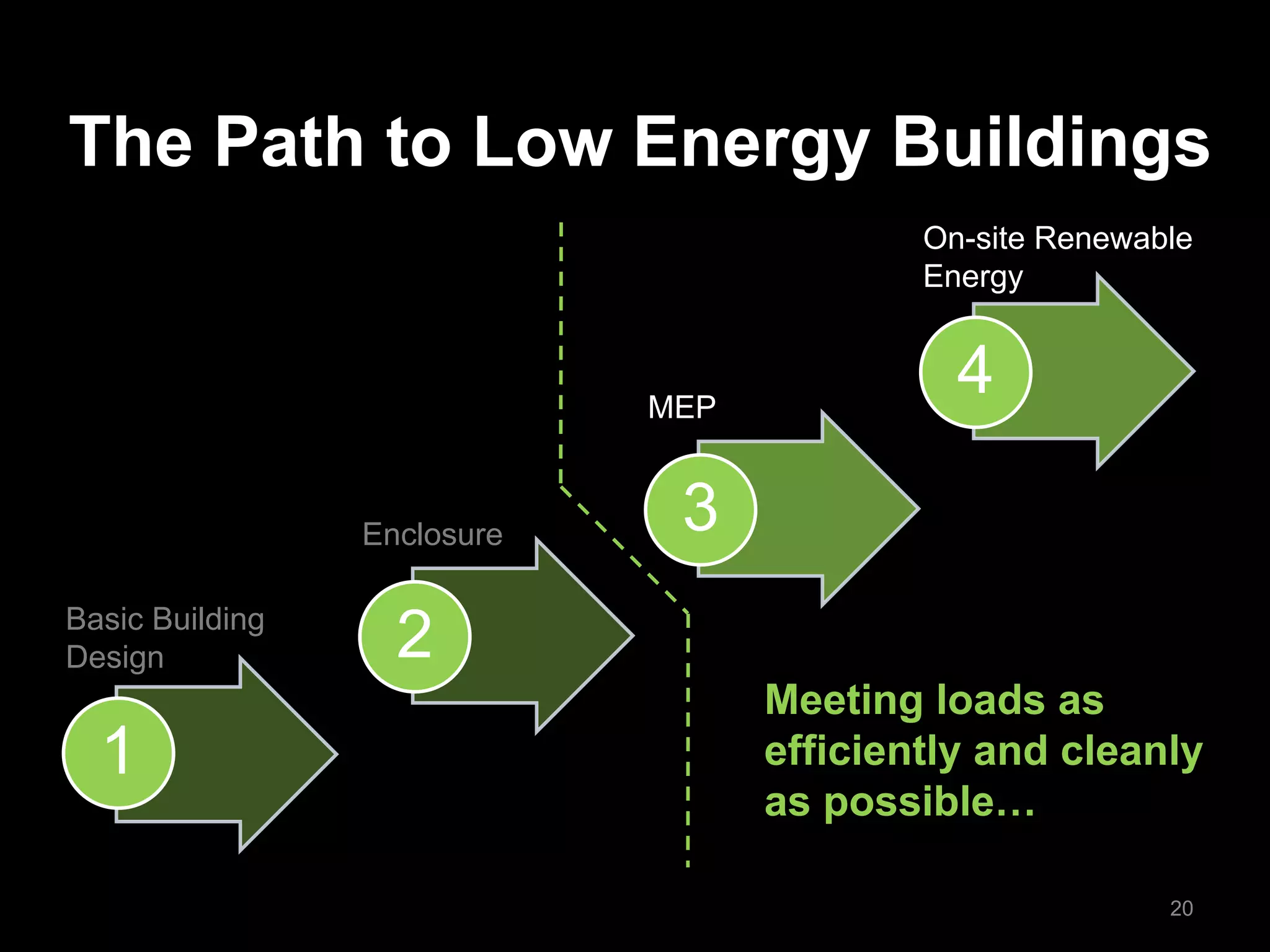

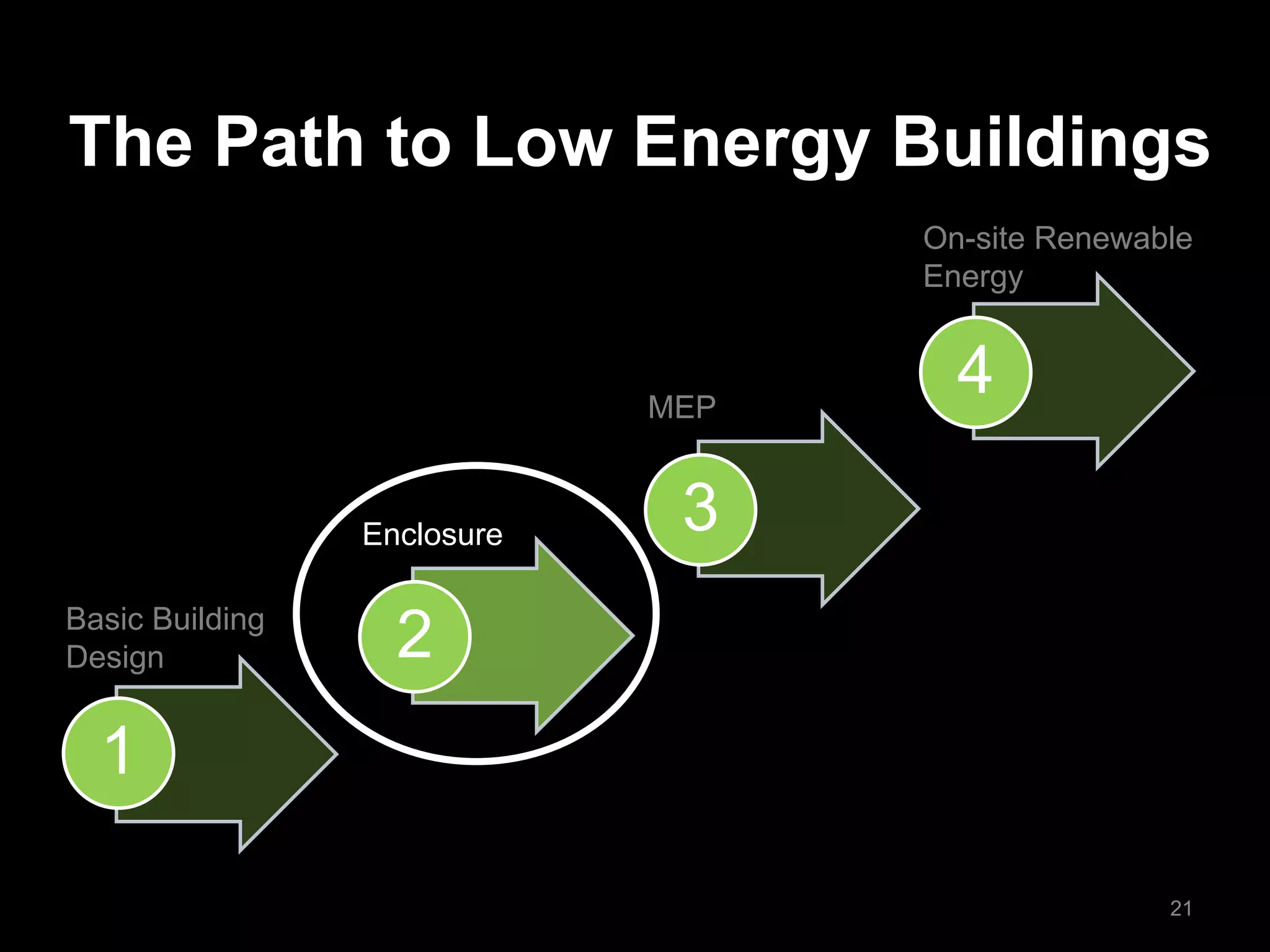

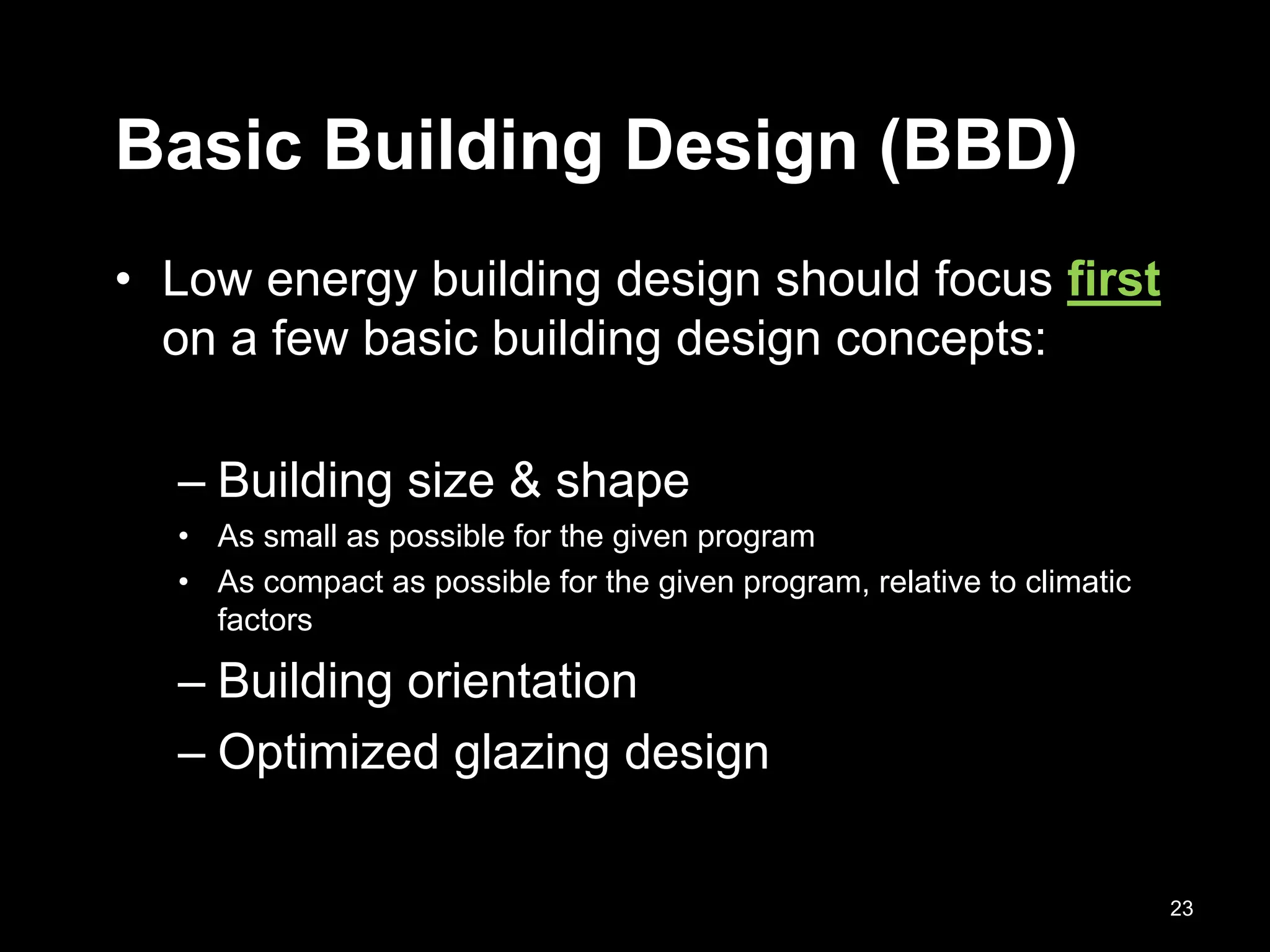

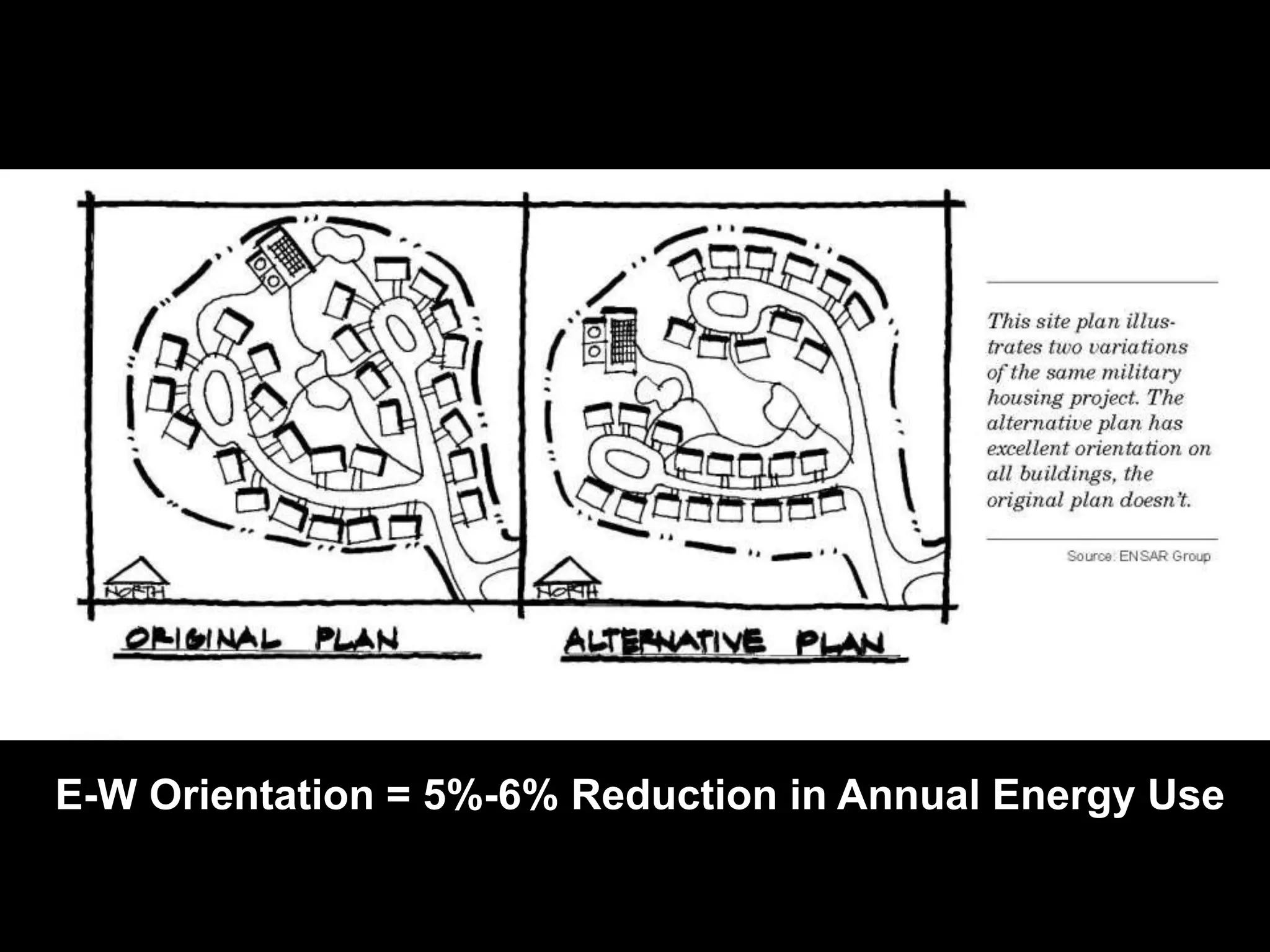

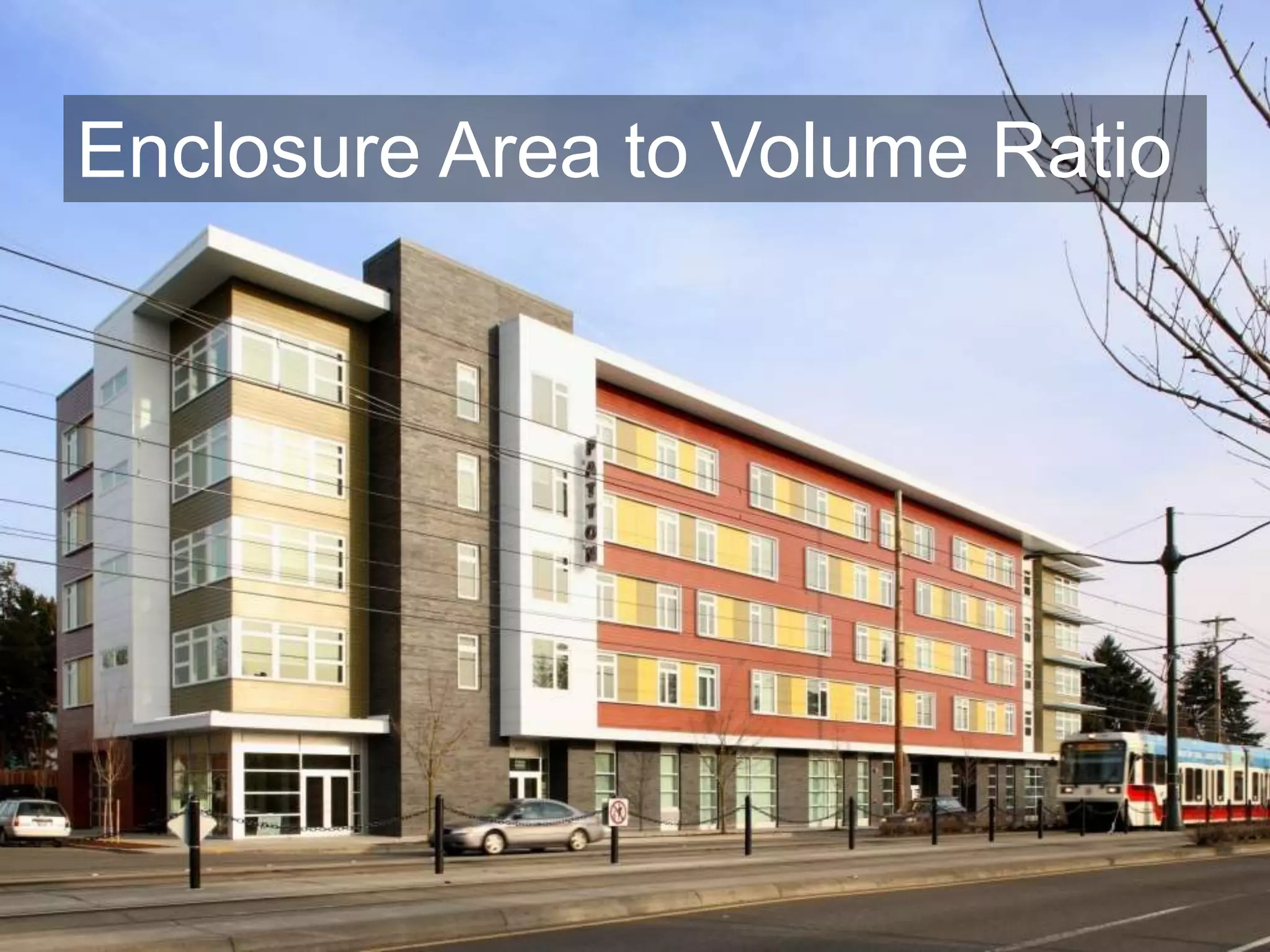

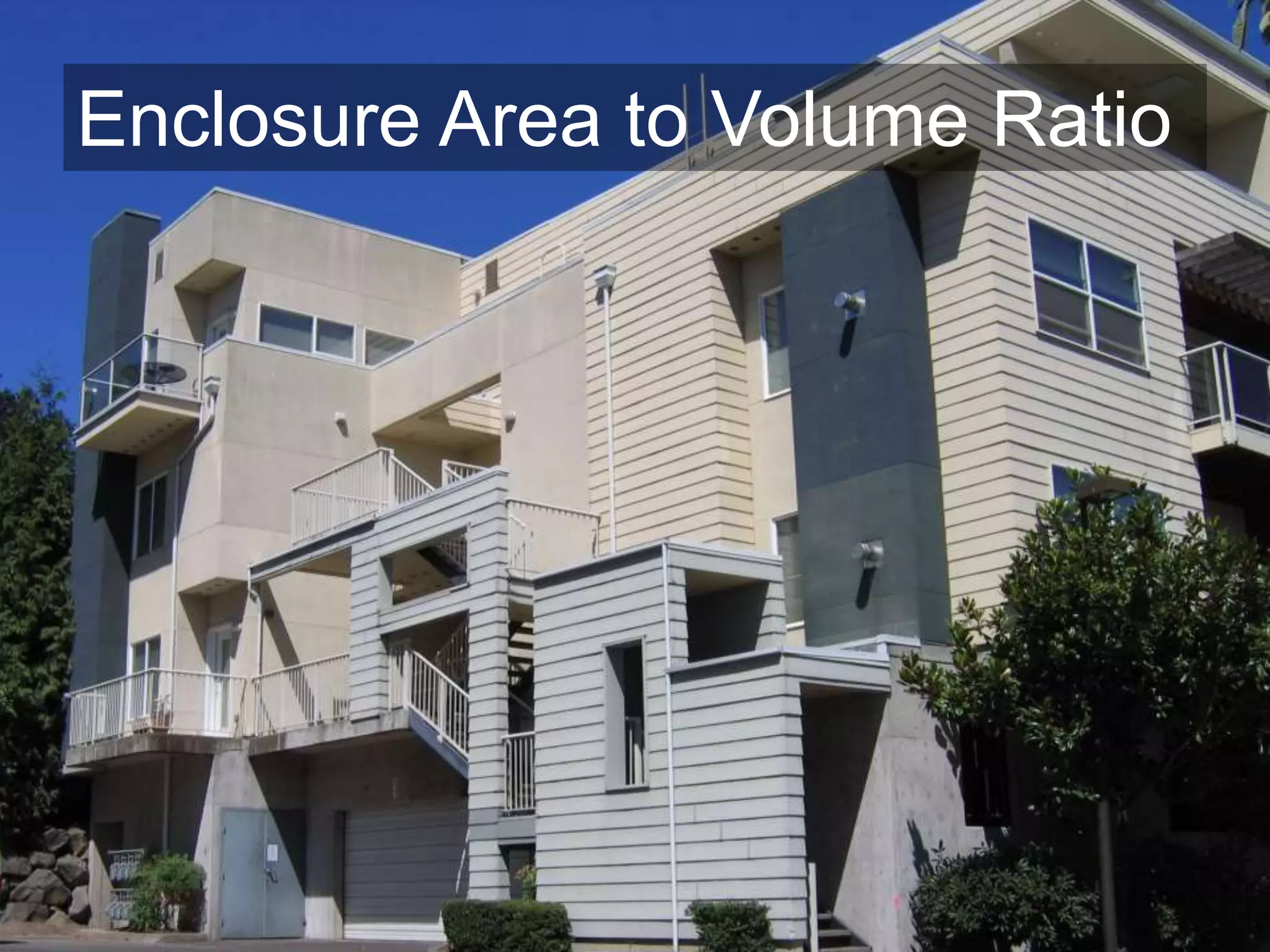

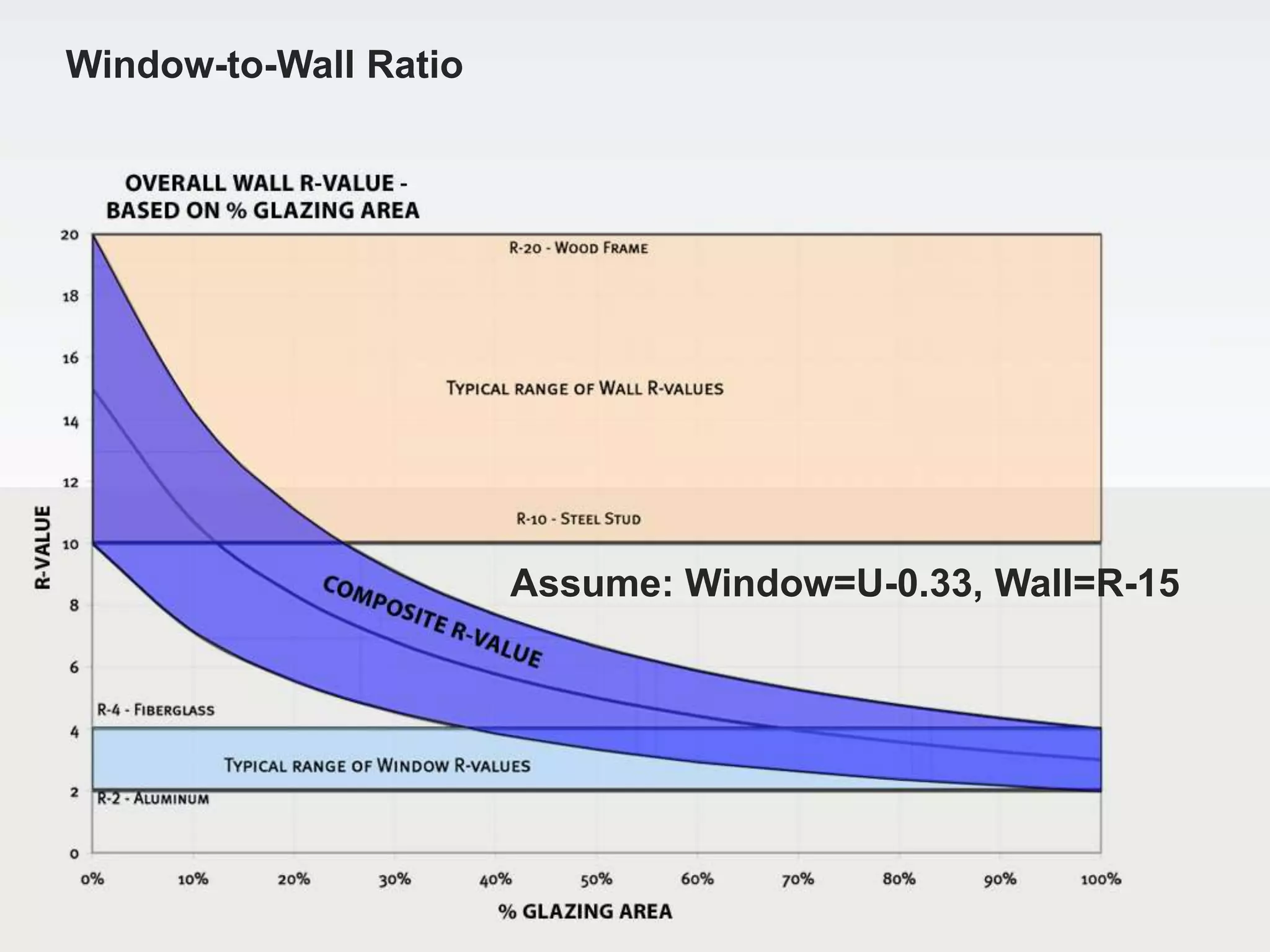

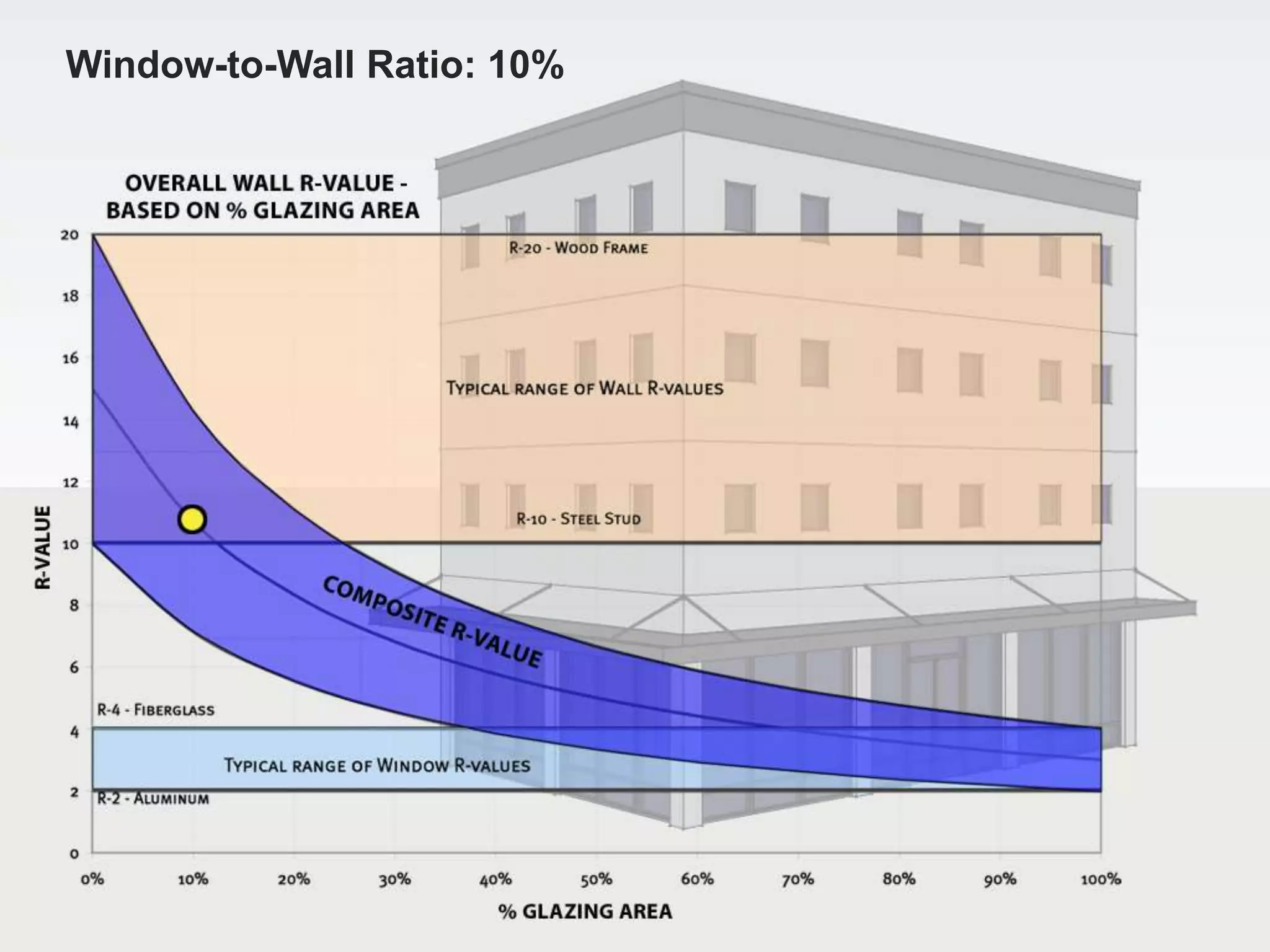

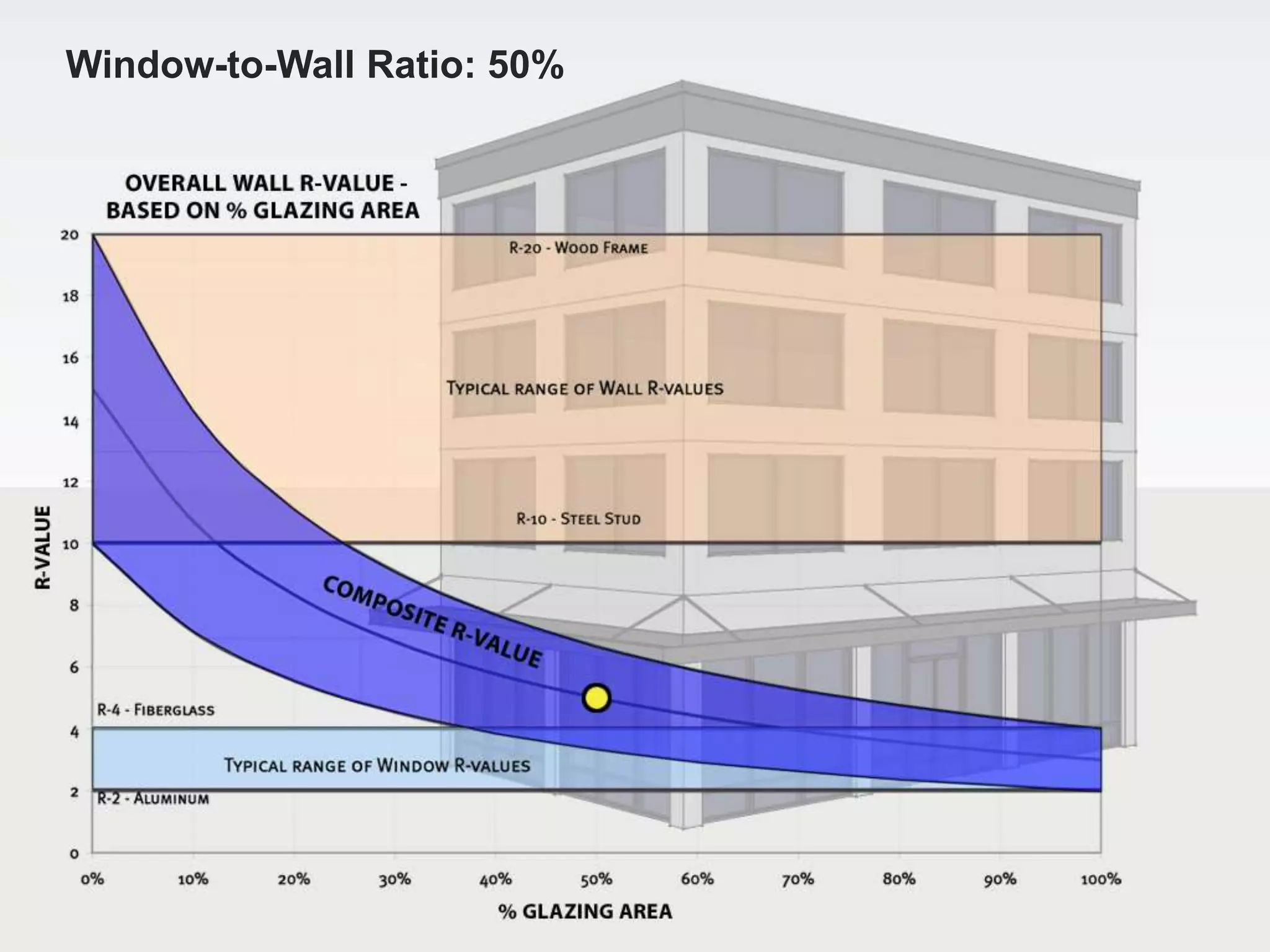

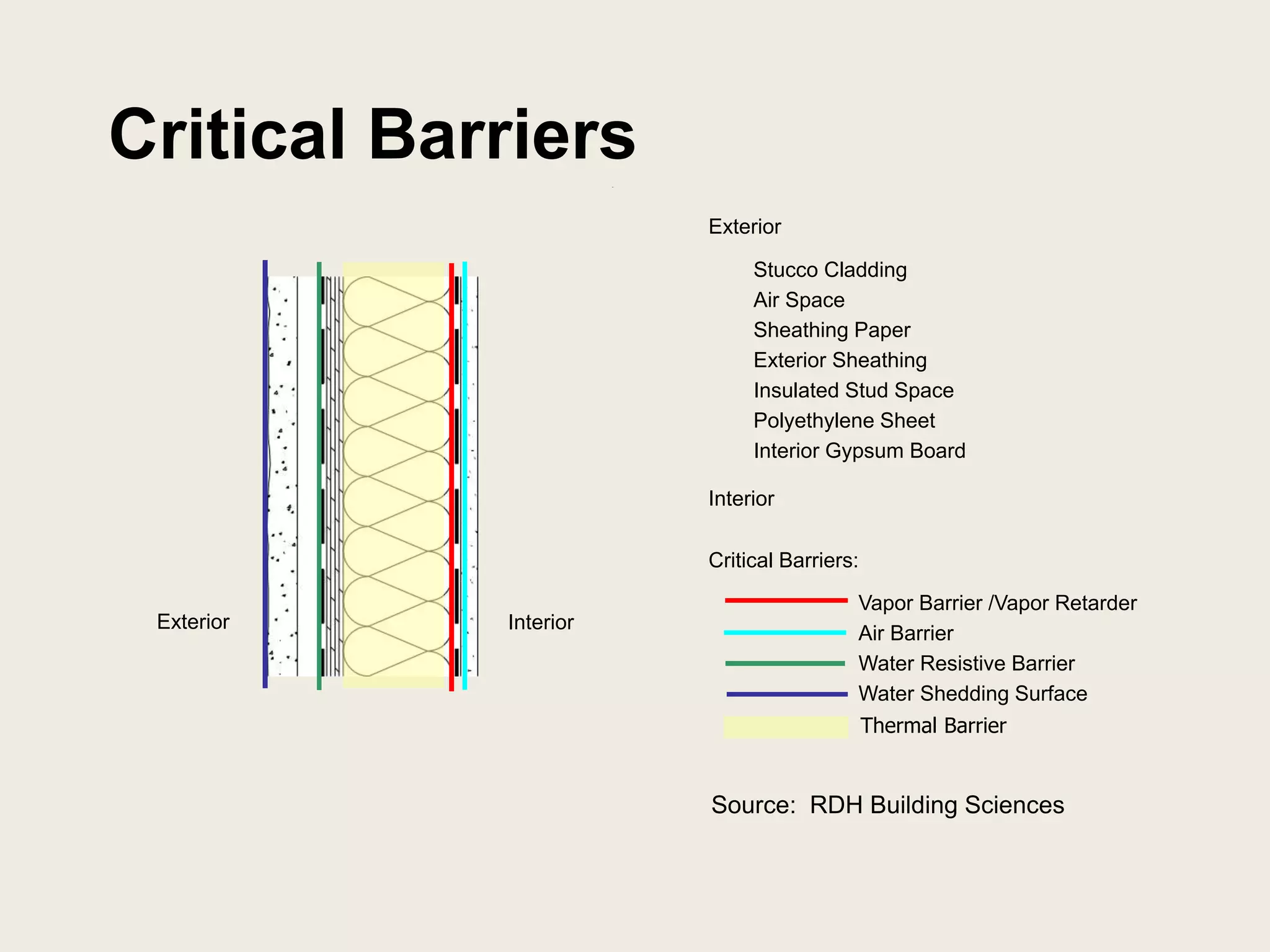

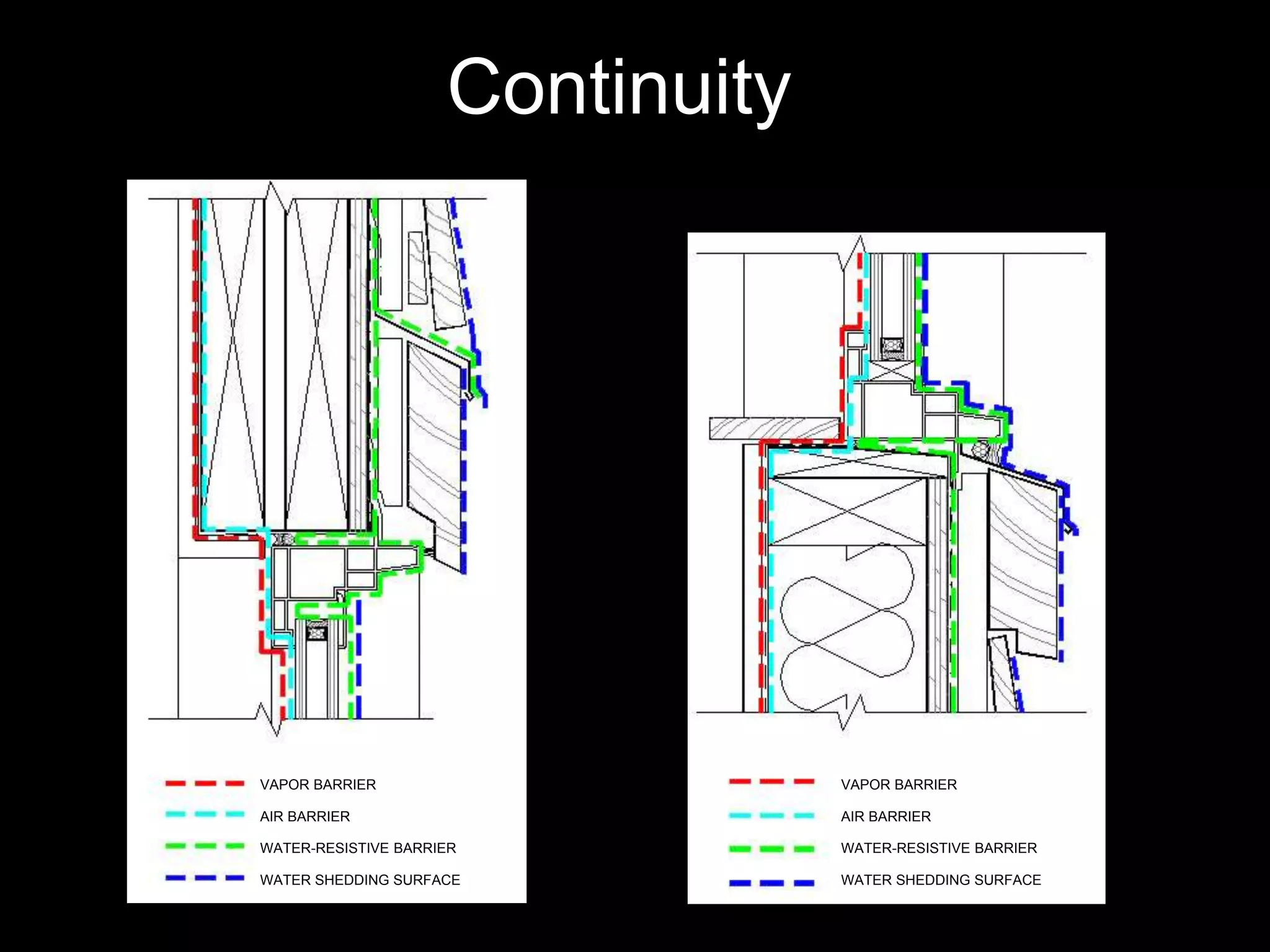

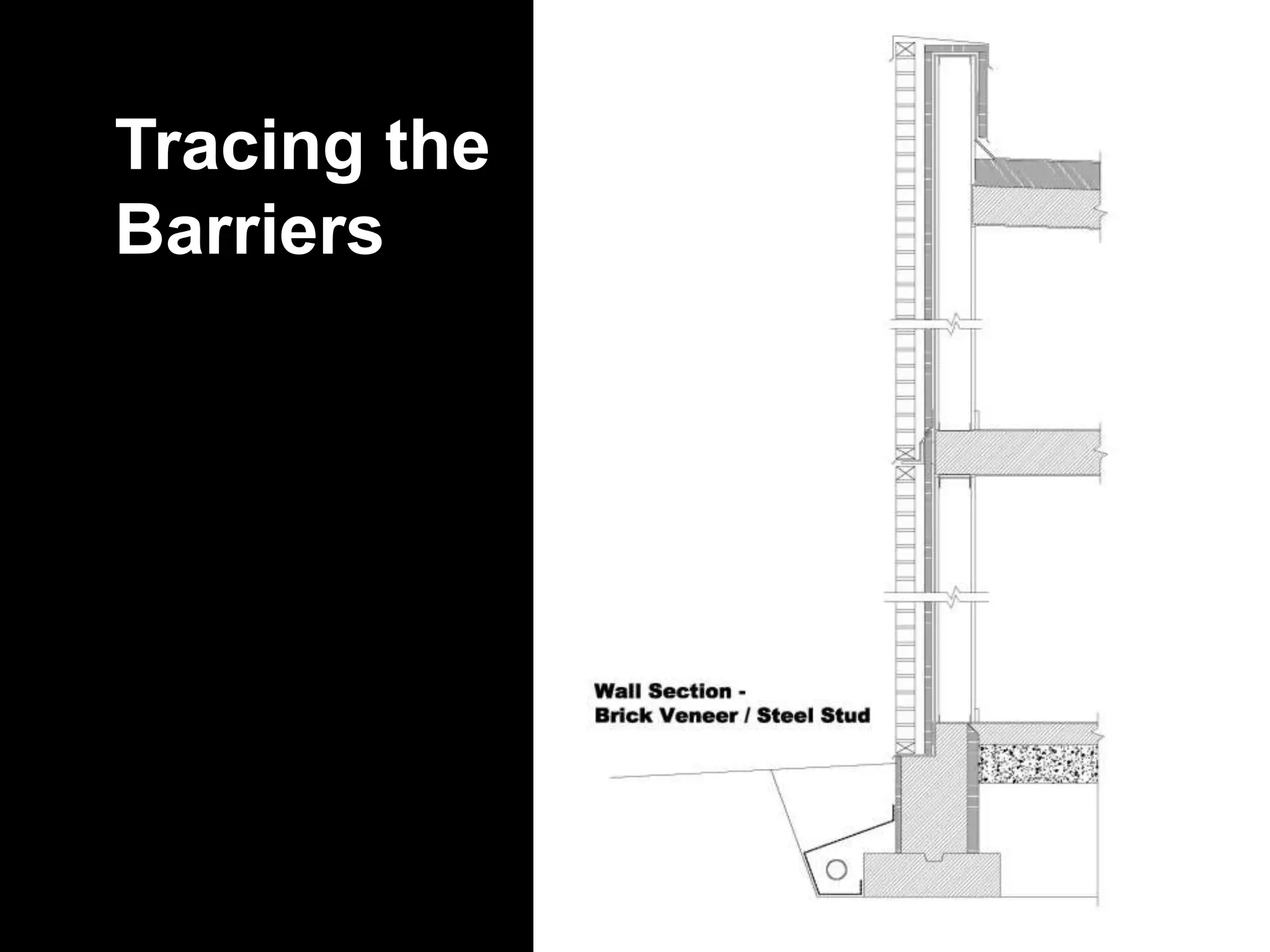

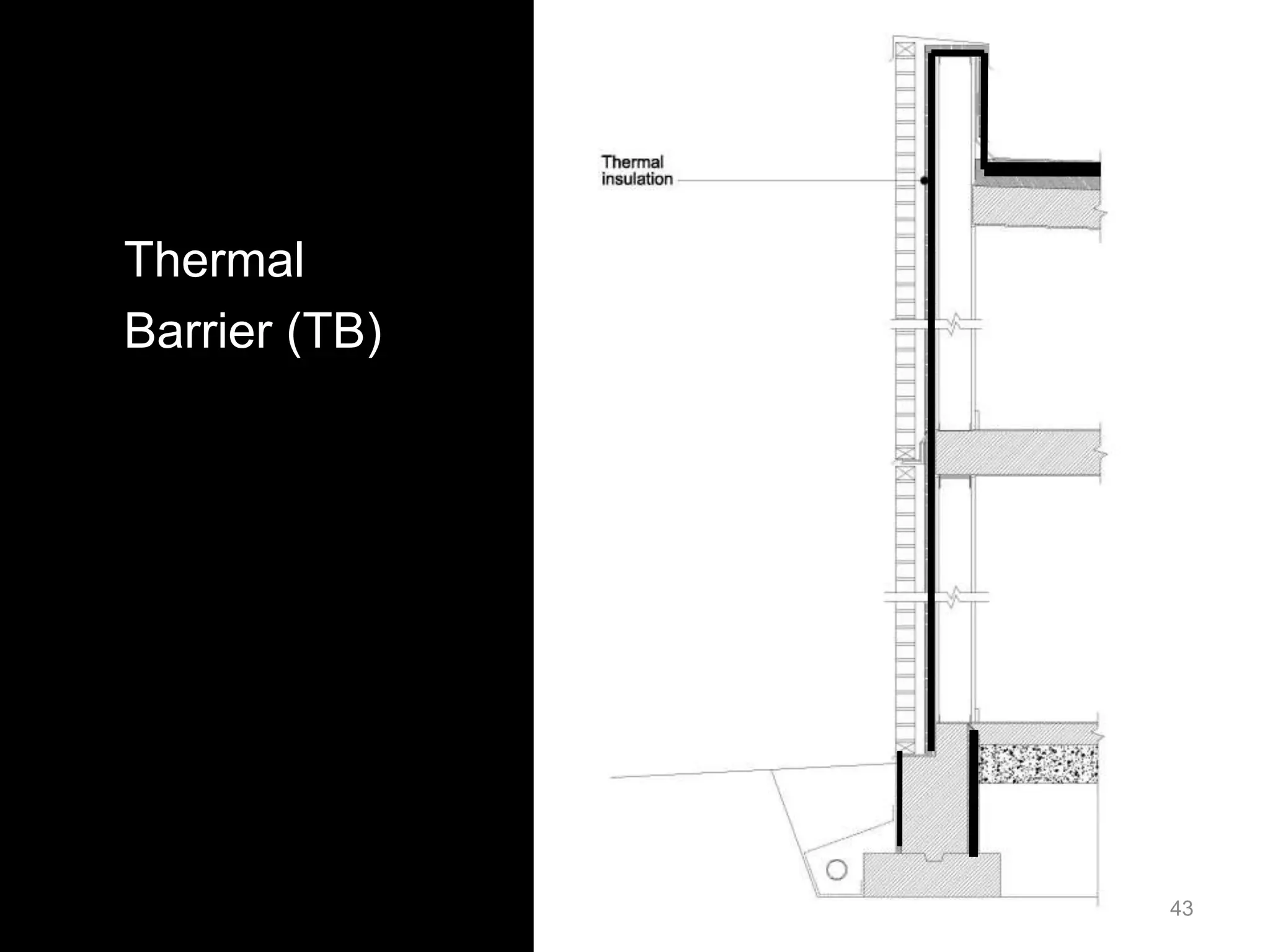

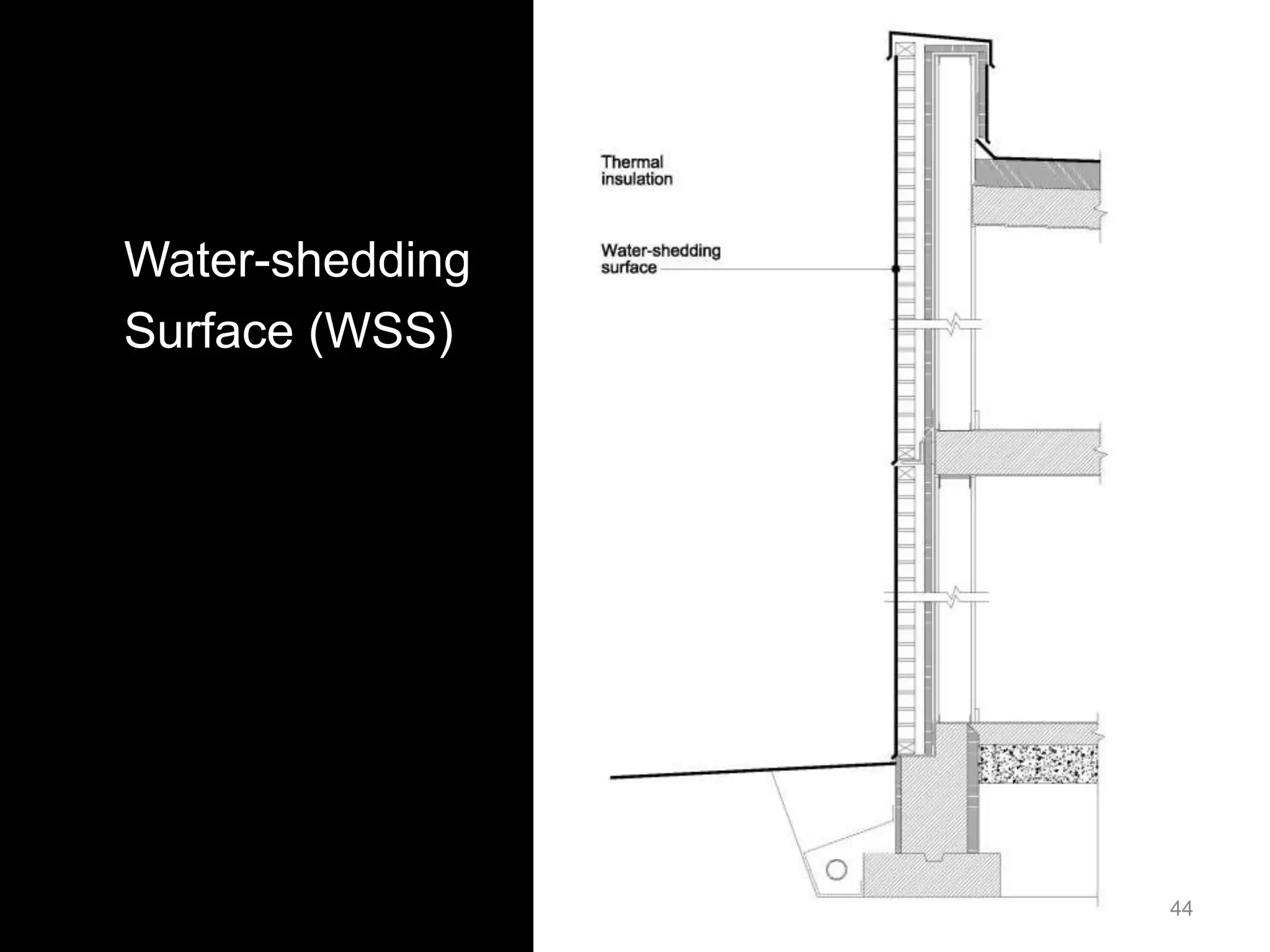

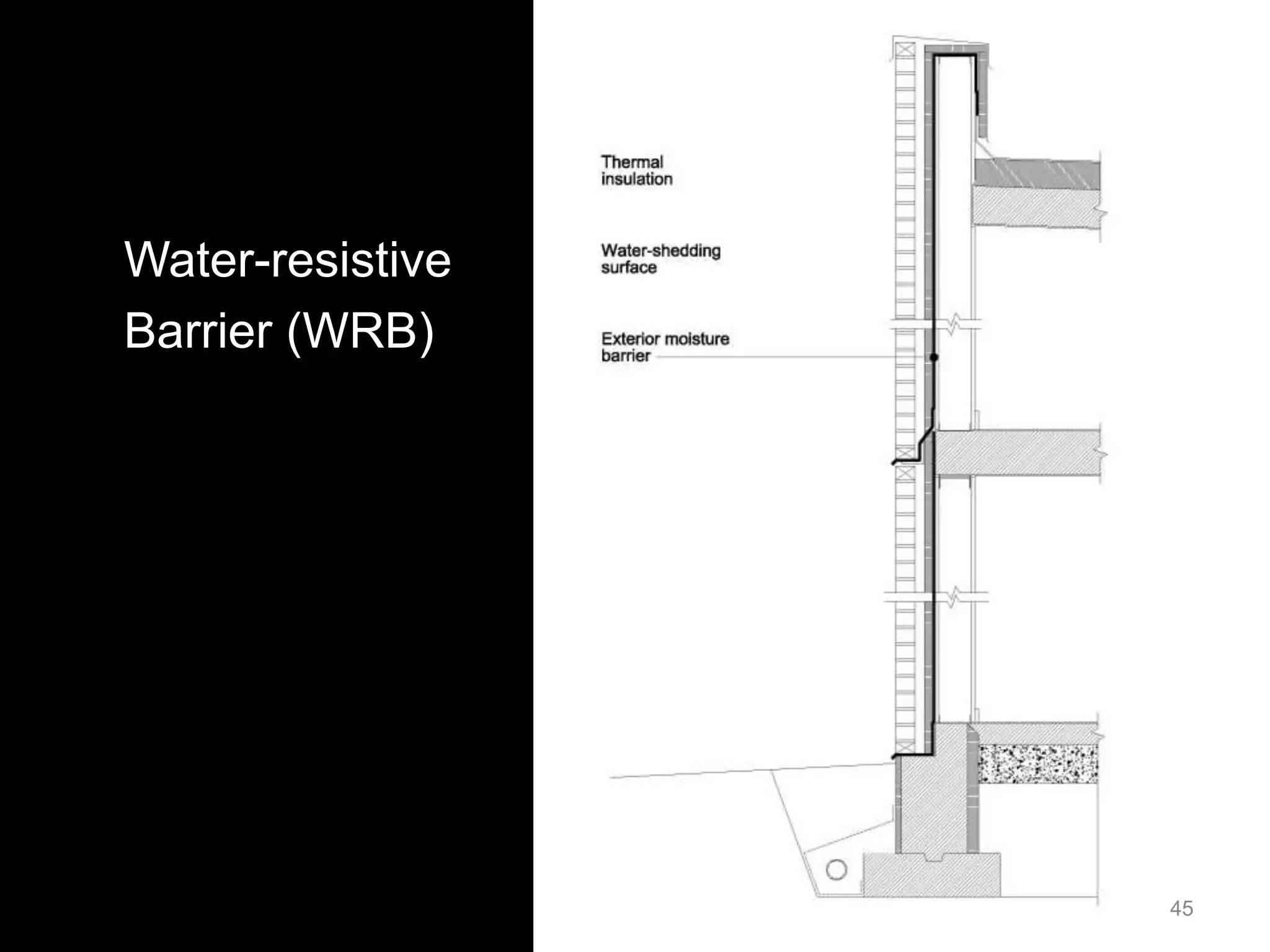

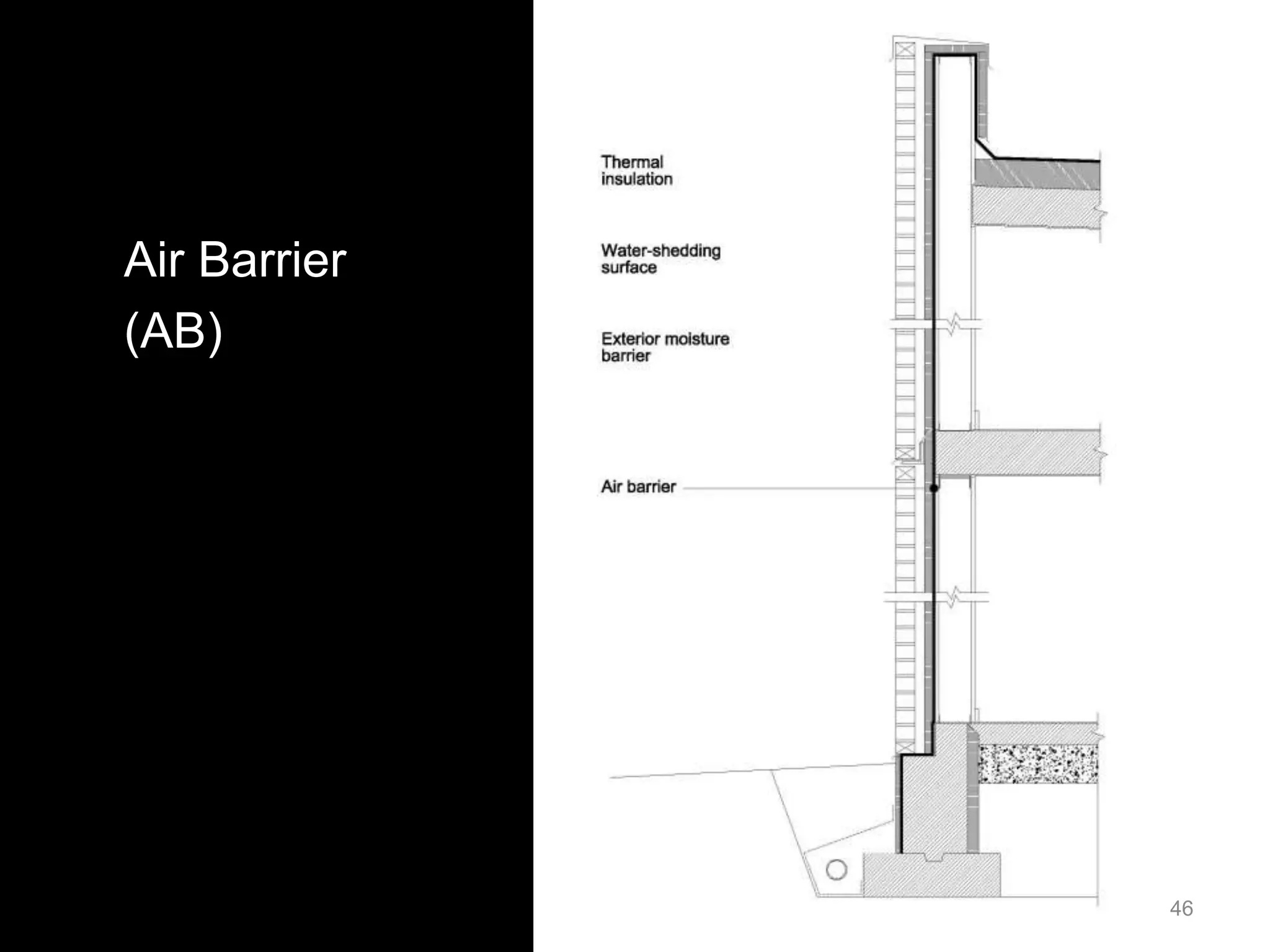

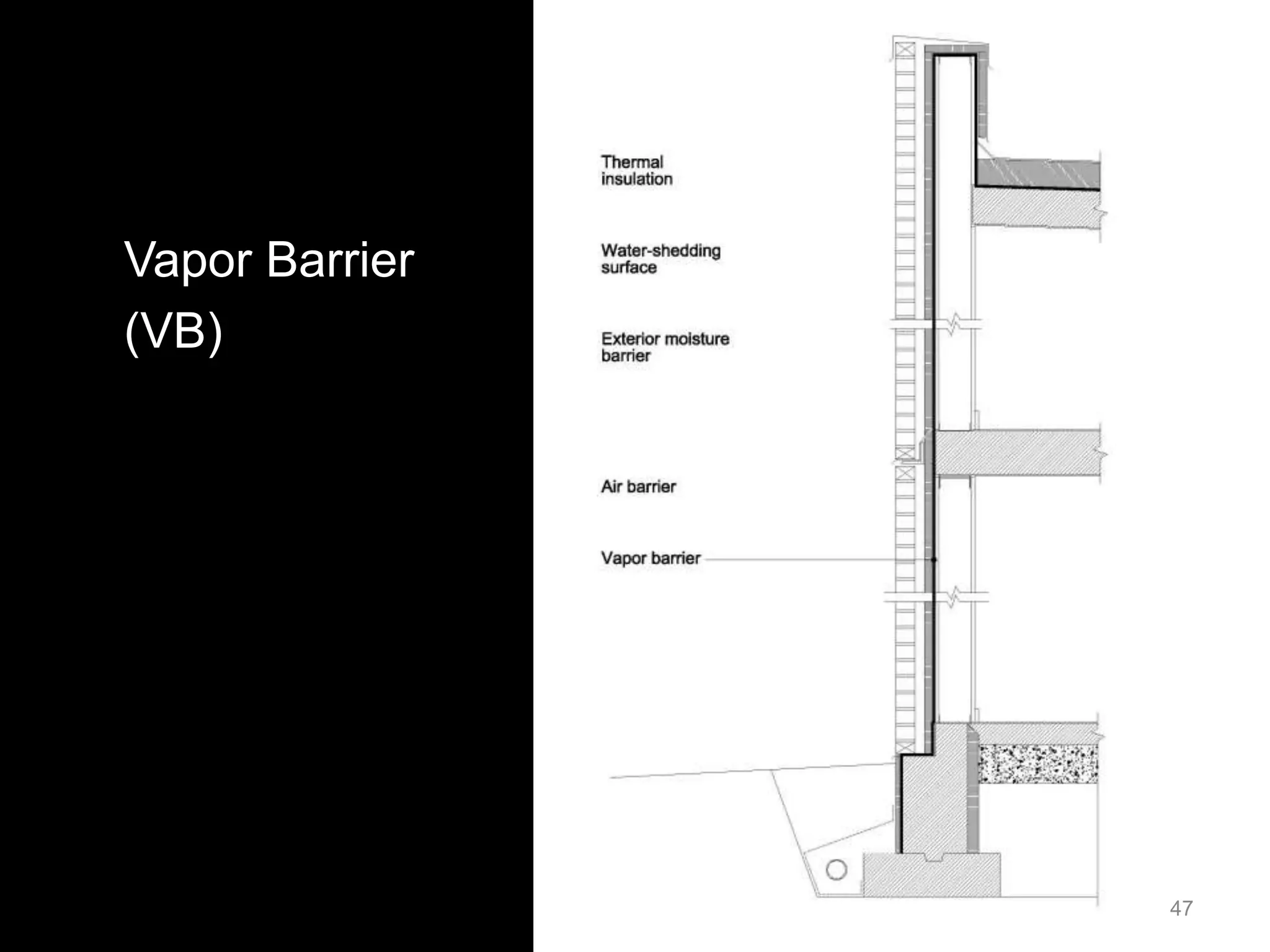

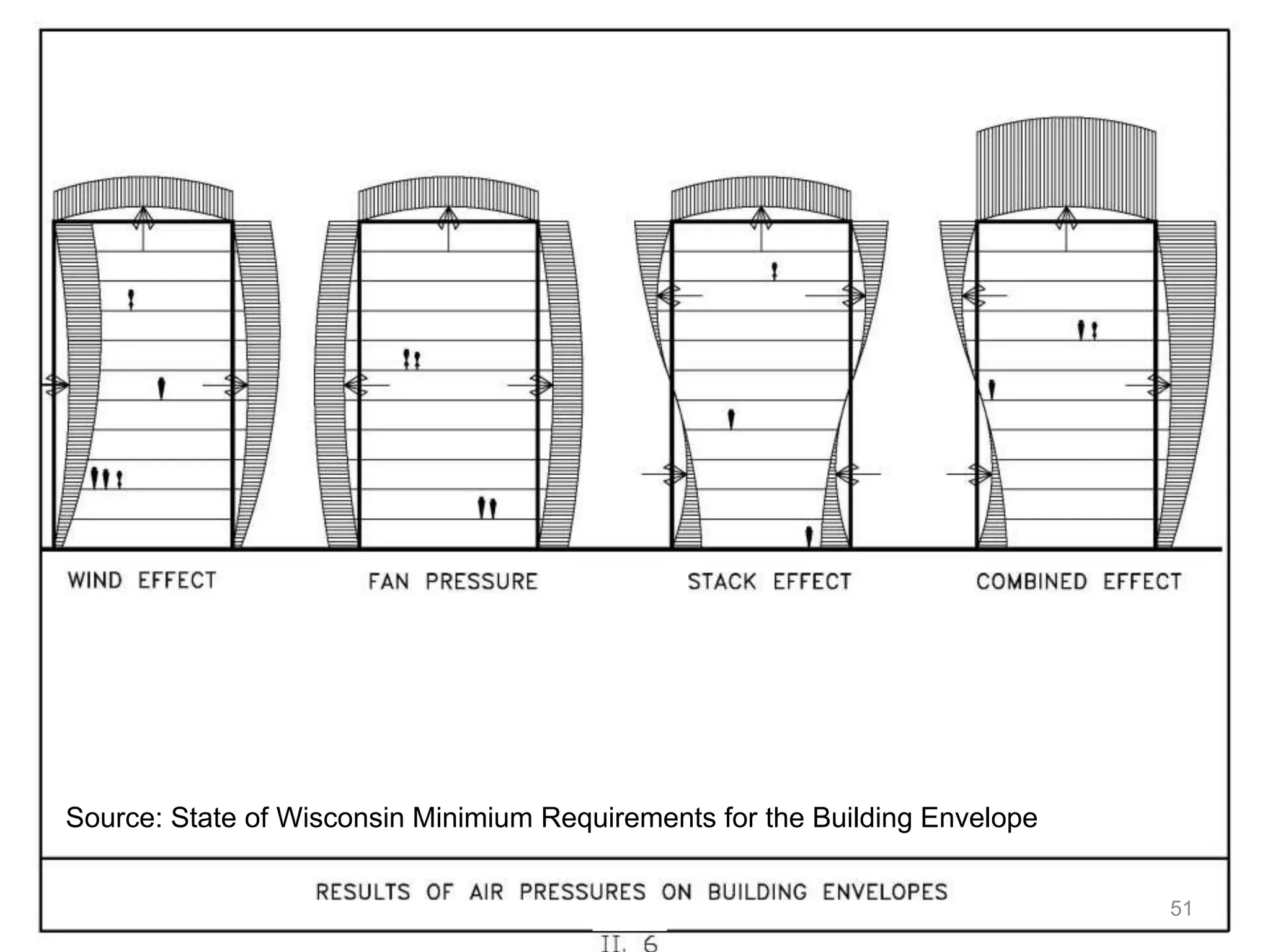

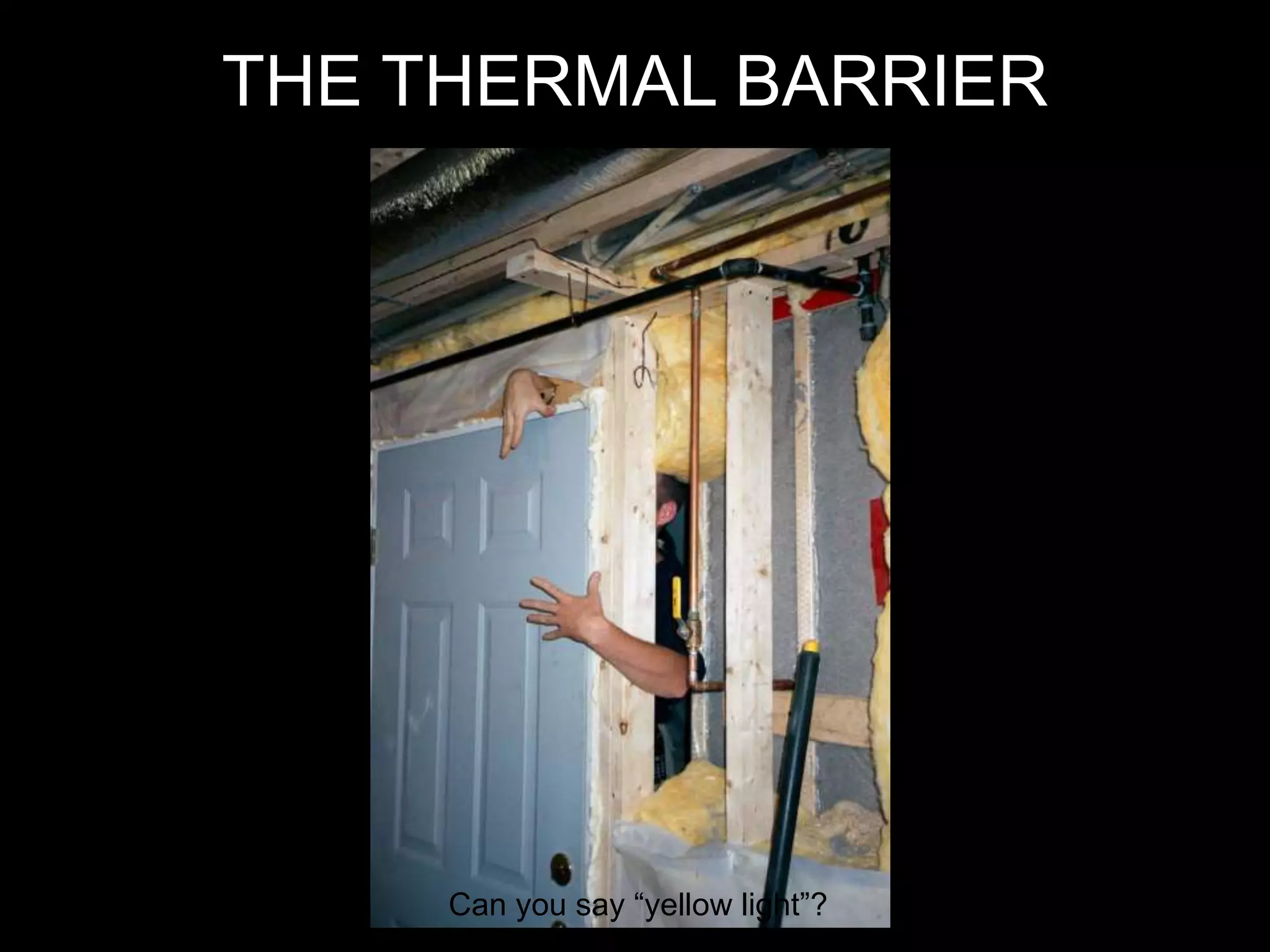

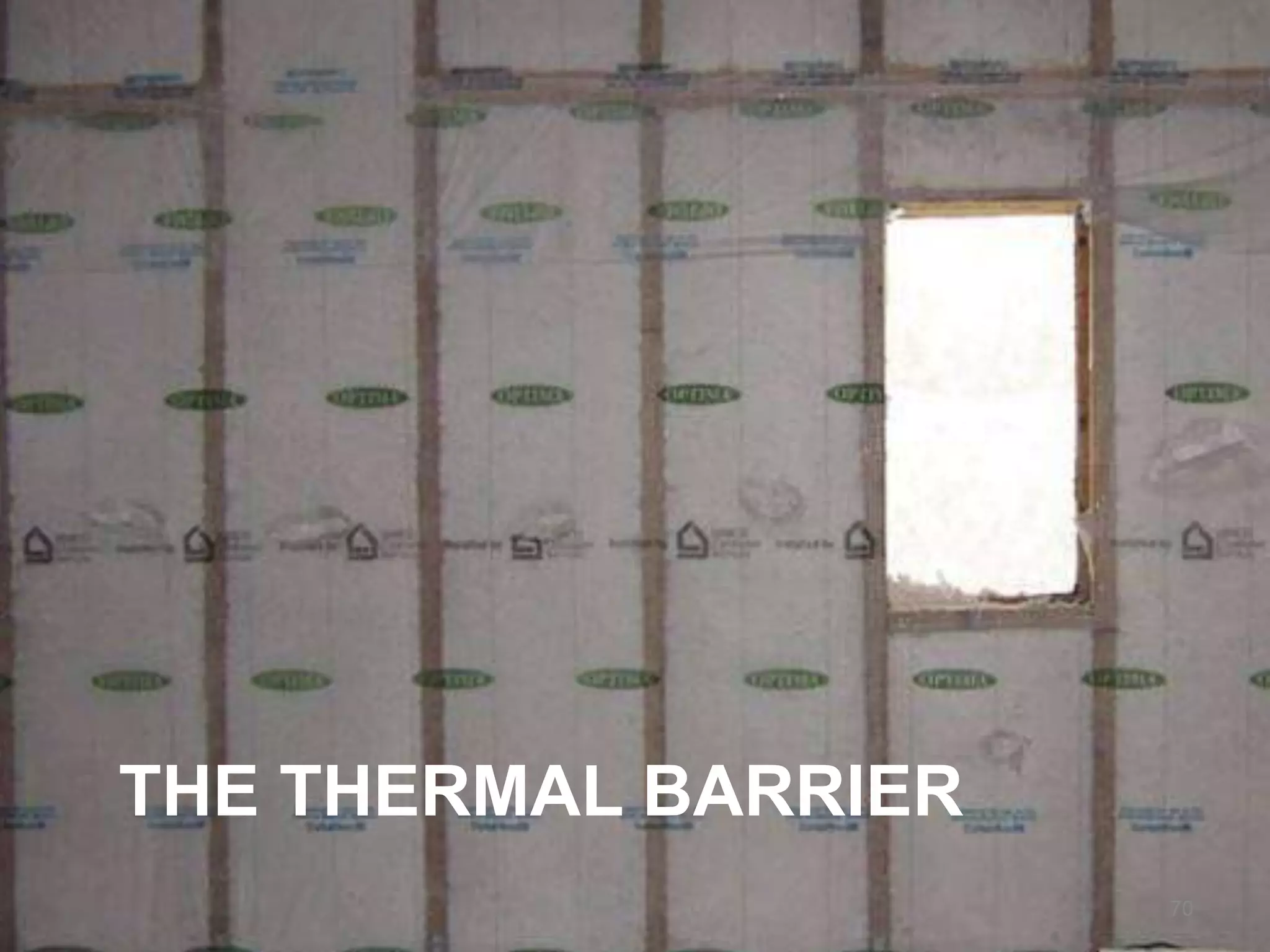

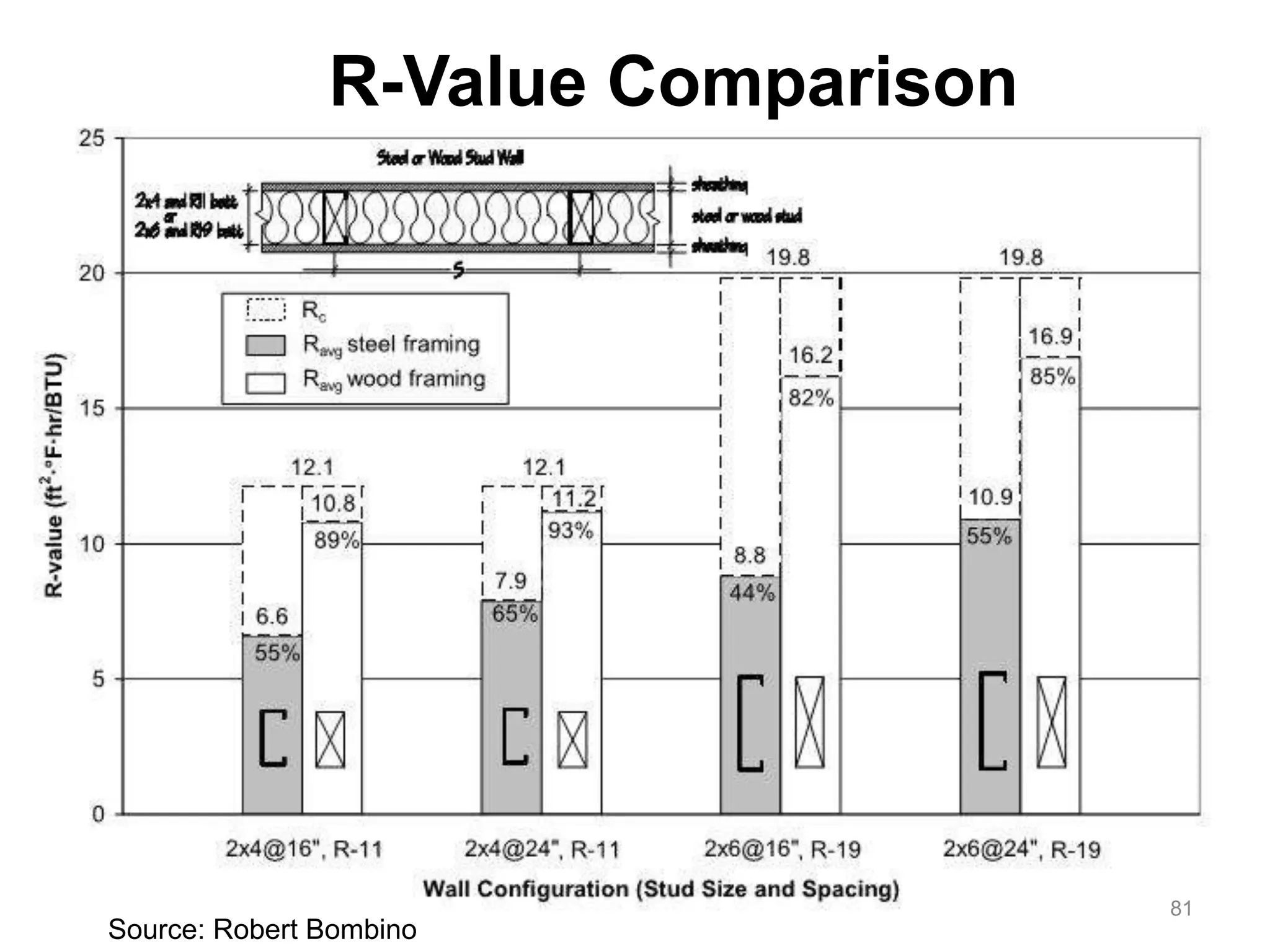

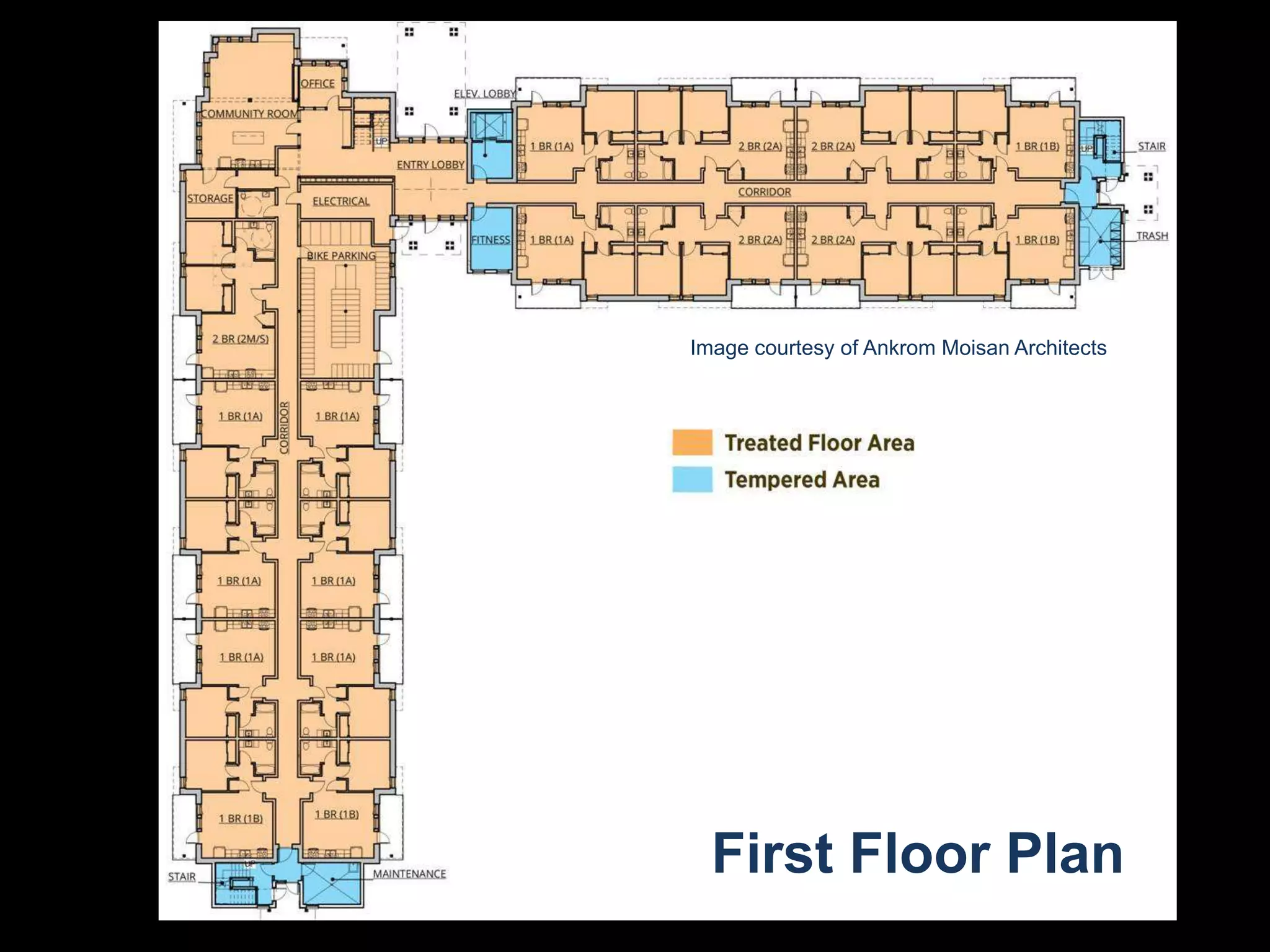

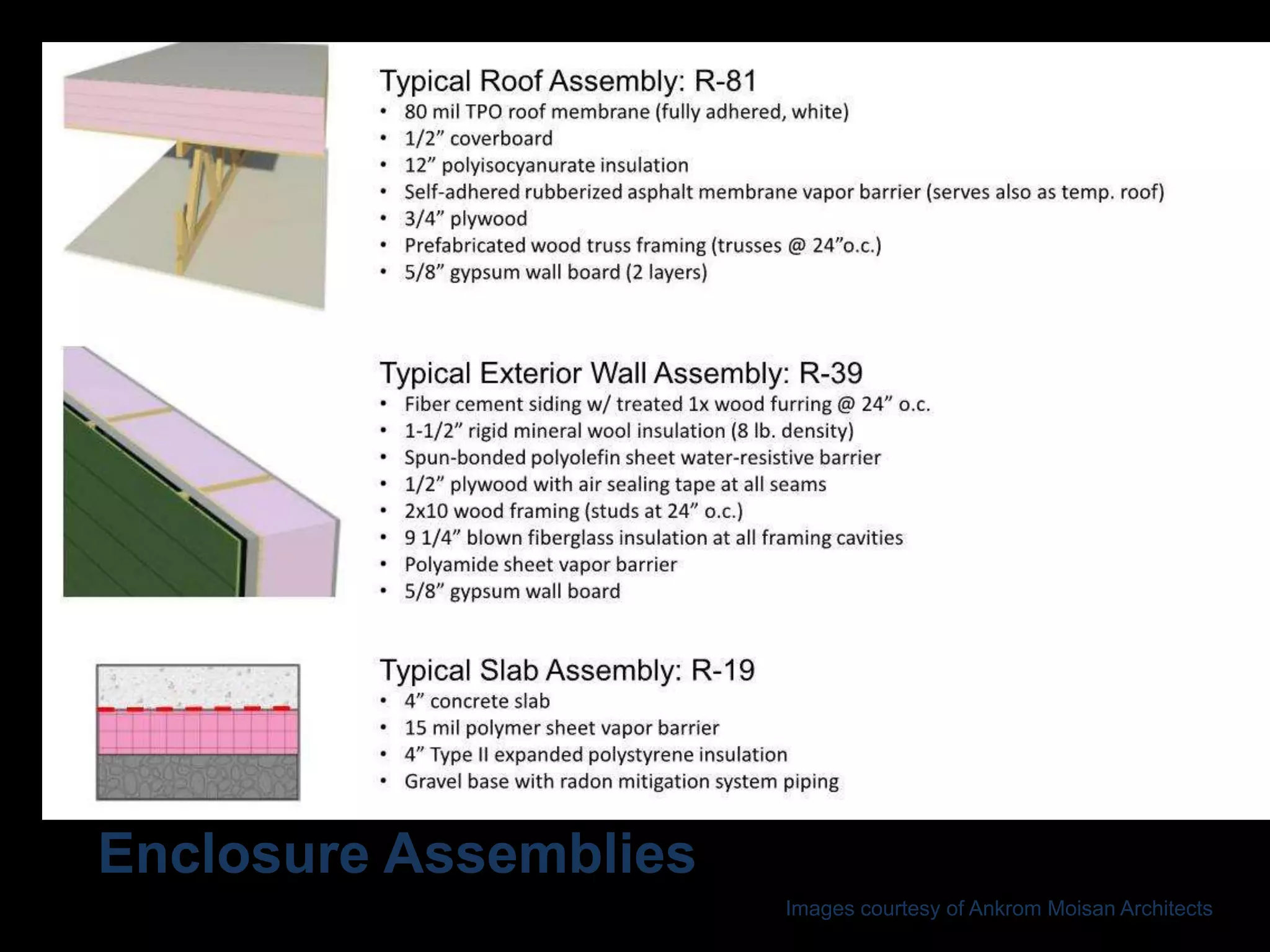

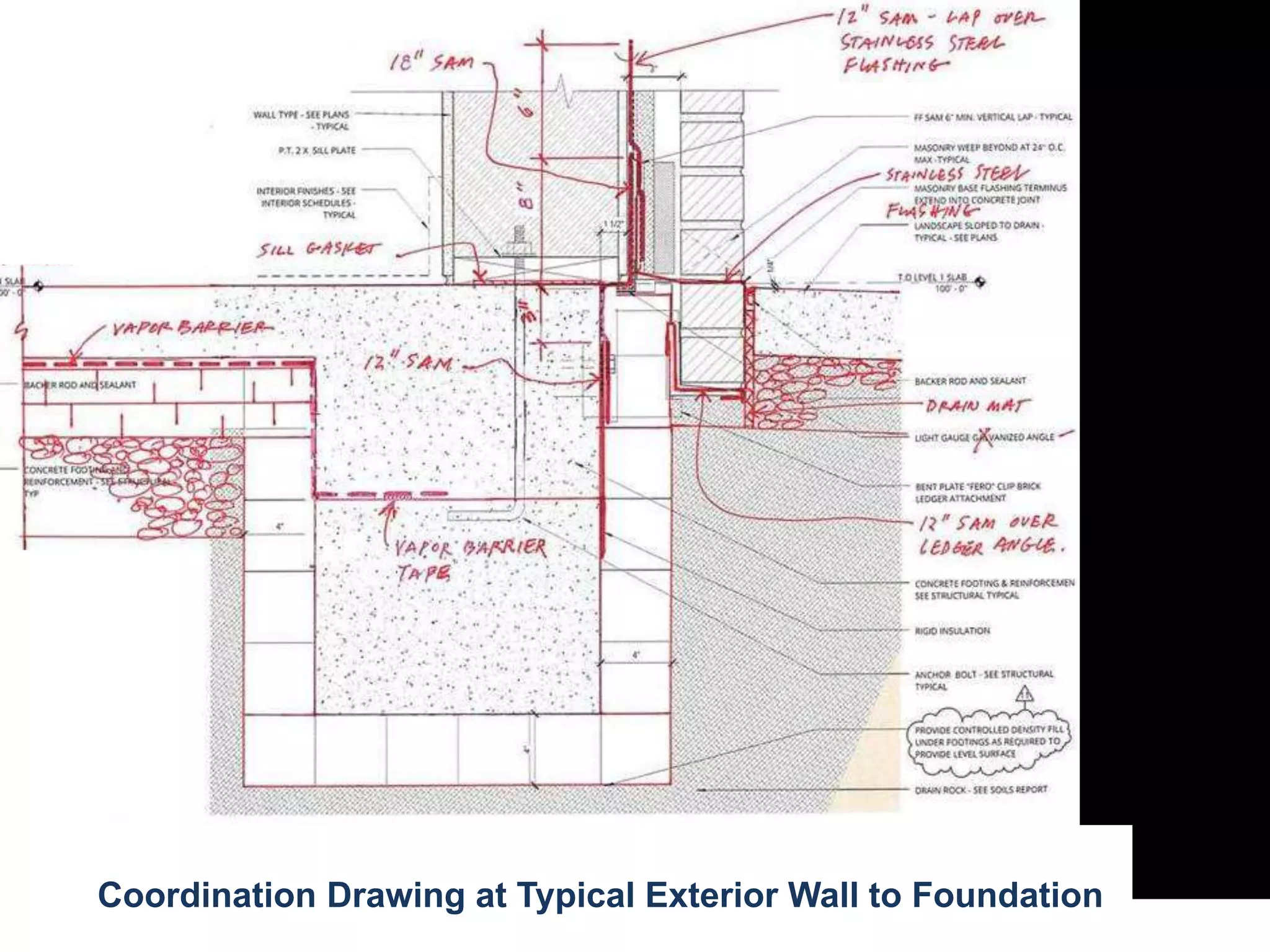

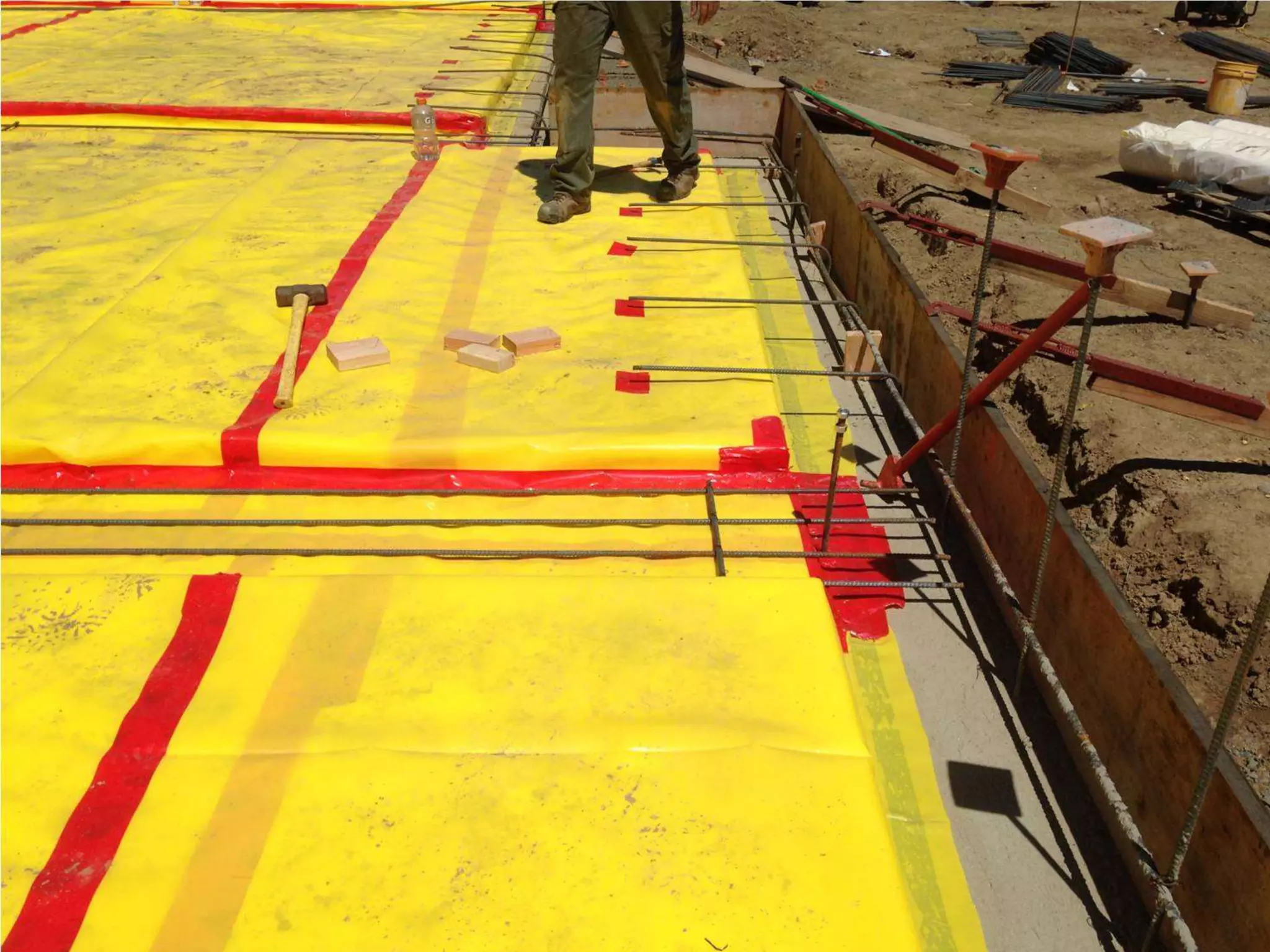

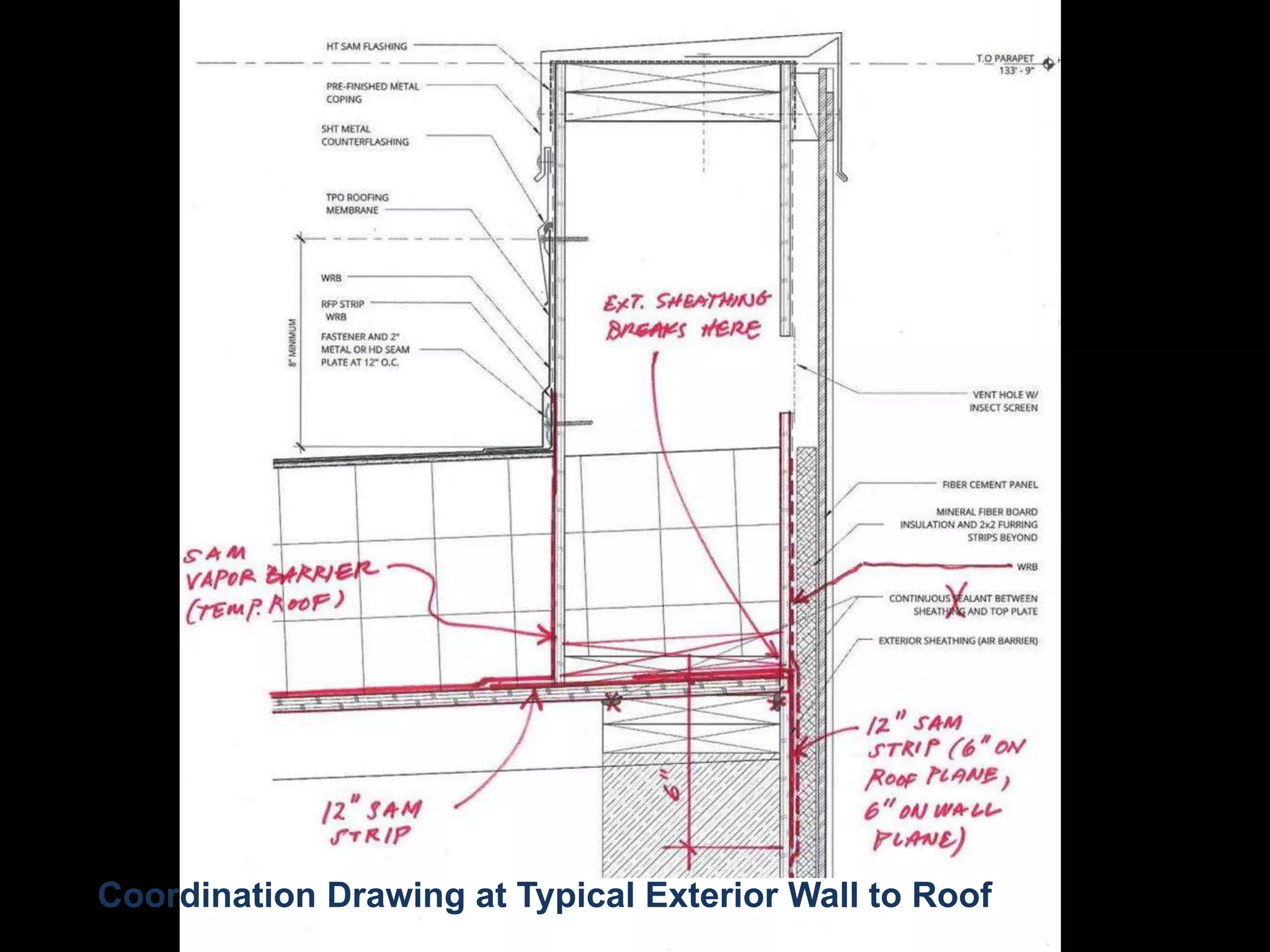

This document provides an overview of an enclosure design training presentation focused on low energy buildings. The presentation covers definitions of key terms, the five critical barriers in enclosure design including the thermal and air barriers, approaches to designing continuous barriers, and details of enclosure assemblies. It emphasizes the importance of continuity, airtightness, insulation, and coordination between building systems in achieving energy efficiency and durability. Case studies are presented on high performance building enclosures and MEP designs.