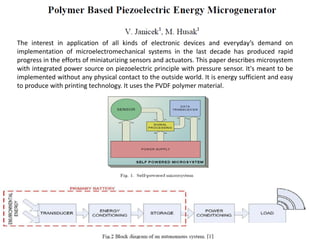

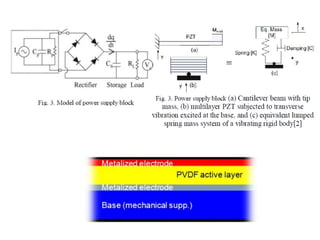

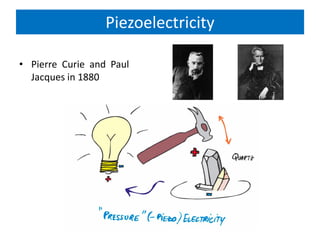

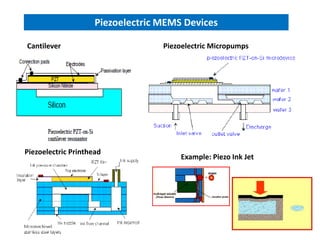

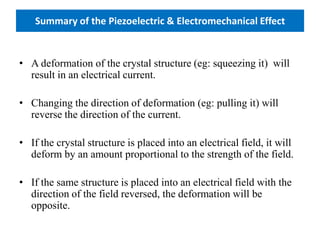

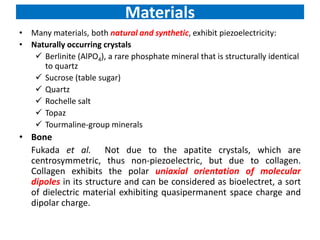

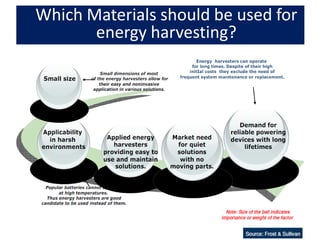

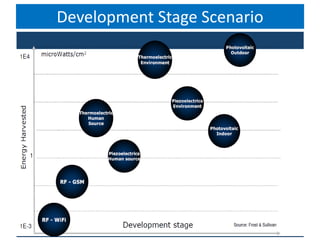

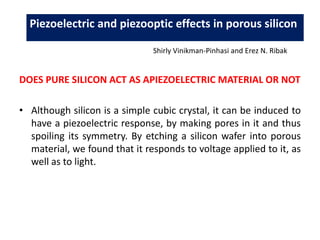

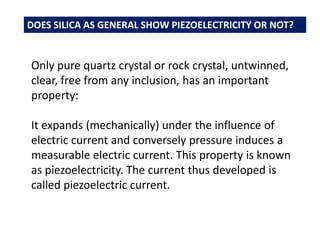

Piezoelectricity involves using crystals that generate an electric charge in response to applied mechanical stress. Some materials that exhibit piezoelectricity include quartz, bone, wood, and synthetic ceramics. The document discusses the piezoelectric effect and electromechanical effect at the crystal structure level. It also provides the mathematical descriptions and constitutive equations for relating mechanical and electrical behavior in piezoelectric materials. The main applications discussed are piezoelectric actuators and transducers used in microelectromechanical systems.

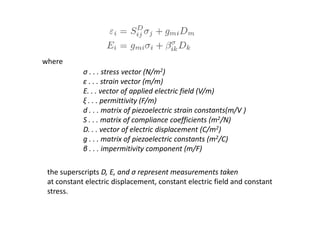

![Other natural materials

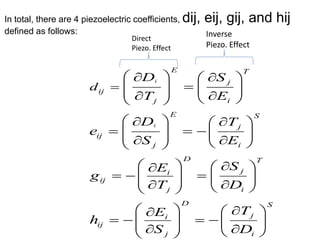

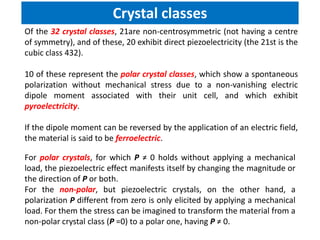

Biological materials exhibiting piezoelectric properties include:

Tendon

Silk

Wood due to piezoelectric texture

Enamel

Dentin

DNA

Synthetic crystals

Gallium orthophosphate (GaPO4), a quartz analogic crystal

Langasite (La3Ga5SiO14), a quartz analogic crystal

Synthetic

ceramics

Barium titanate (BaTiO3)

Lead titanate (PbTiO3)

Lead zirconate titanate (Pb[ZrxTi1−x]O3 0≤x≤1)

Polymers

Polyvinylidene fluoride (PVDF)](https://image.slidesharecdn.com/piezoelectricity-130726144833-phpapp02/85/Piezoelectricity-Think-Locally-Act-Globally-14-320.jpg)

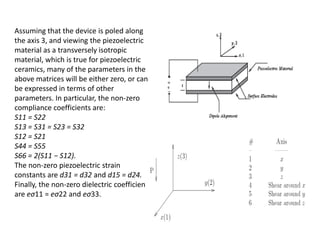

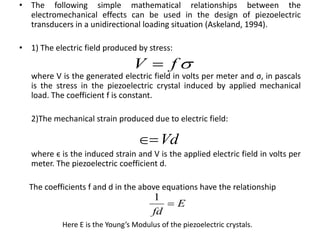

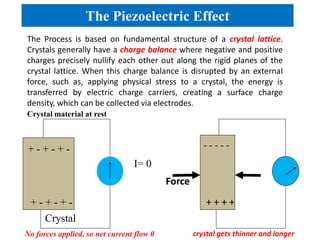

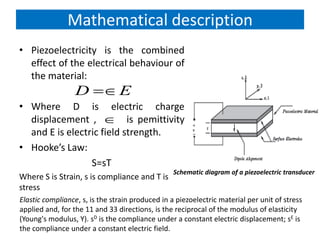

![• These may be combined into so called coupled equations, of which the

strain-charge form is:

Where [d] is the matrix for the direct piezoelectric effect and [dt] is the matrix for the

converse piezoelectric effect. The superscript E indicates a zero, or constant, electric field; the

superscript T indicates a zero, or constant, stress field; and the superscript t stands for

transposition of a matrix.

t T

E

S s T d E

D d T E

where the indexes i, j = 1, 2, . . . ,6

and m, k = 1, 2, 3 refer to different

directions within the material

coordinate system.](https://image.slidesharecdn.com/piezoelectricity-130726144833-phpapp02/85/Piezoelectricity-Think-Locally-Act-Globally-22-320.jpg)