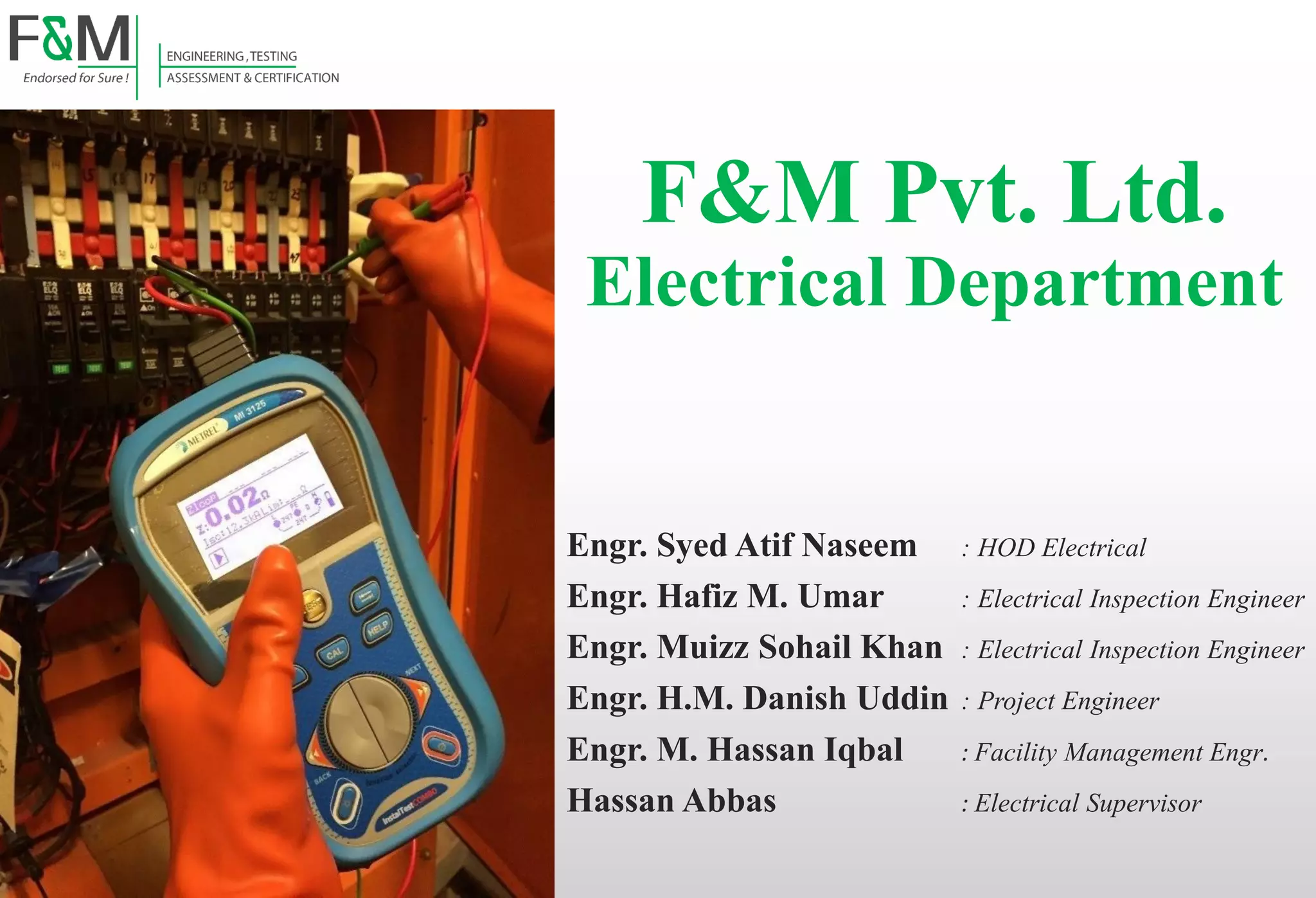

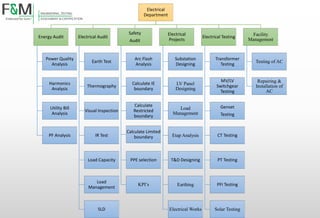

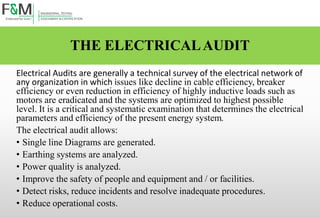

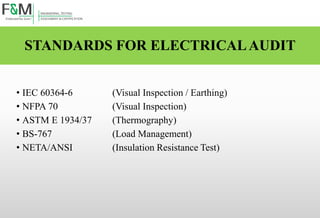

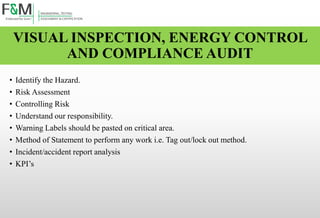

This document provides information on the electrical department of F&M Pvt. Ltd., including a list of engineers and their roles. It then discusses various services offered by the department, such as electrical audits, safety audits, load analysis, and projects. Electrical audits are described as examining the electrical parameters and efficiency of an energy system to identify issues and optimize performance. Safety audits ensure compliance with standards to improve safety and reduce risks. The department uses various tools and follows international standards in conducting its services.