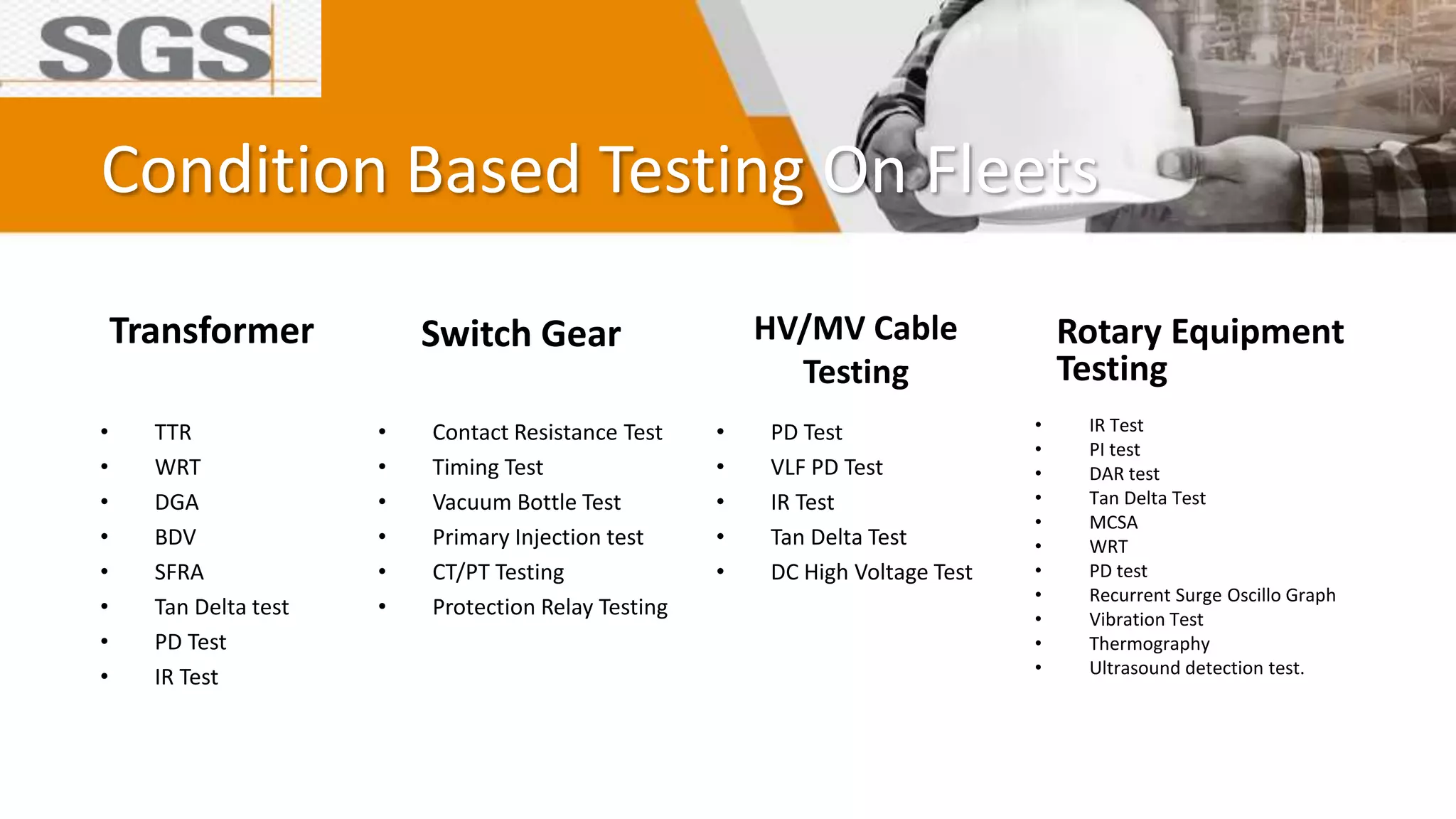

The document discusses asset integrity management and maintenance strategies to achieve ISO 55001 certification for electrical asset fleets. It outlines condition-based testing methods to increase asset reliability and reduce failures. Maintaining assets based on their condition through techniques like predictive maintenance can extend their useful life. Asset health monitoring and life cycle analysis can inform decision making around repair and replacement. The goal is to ensure reliability, availability and maintainability of assets over the long term.