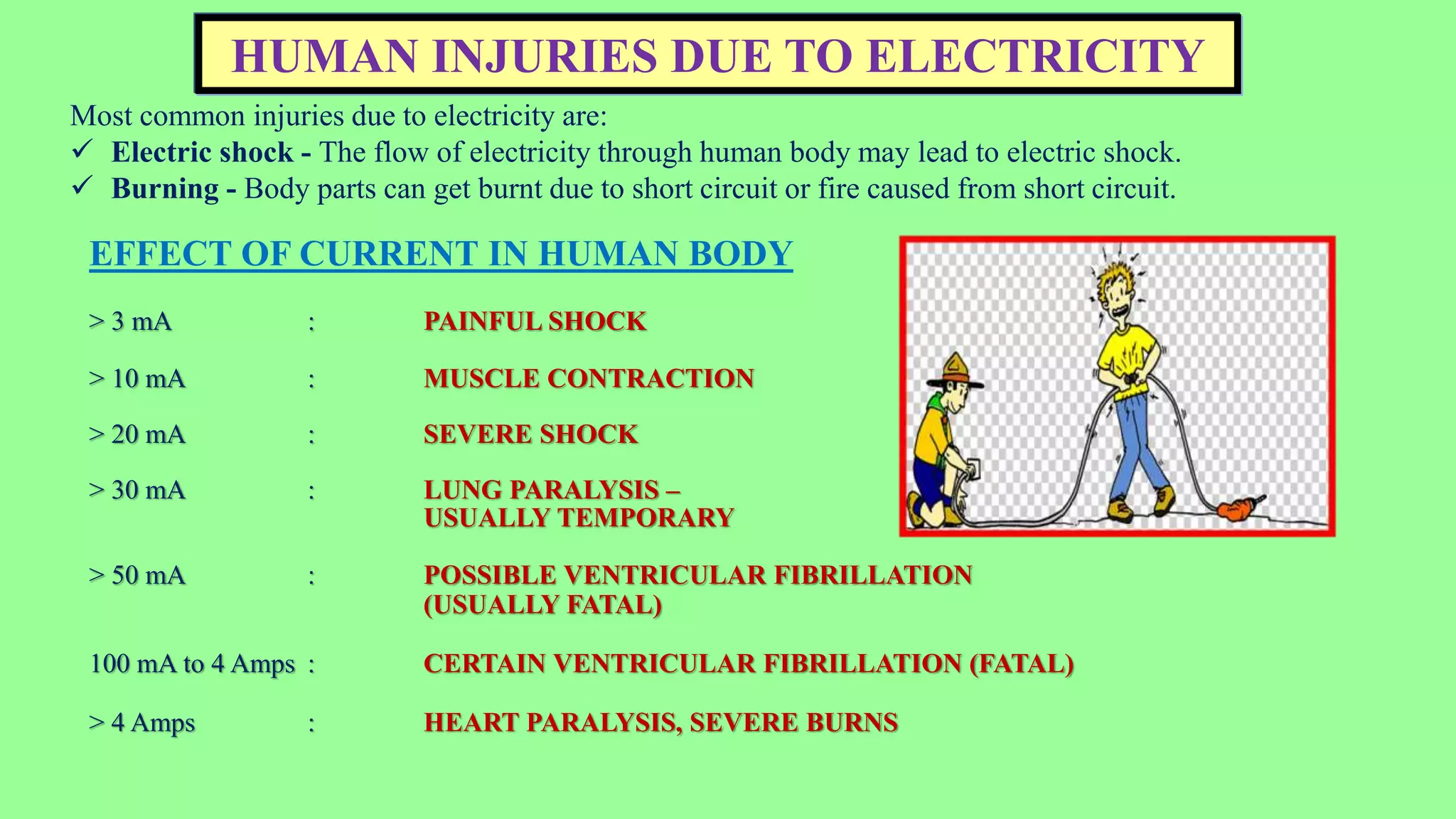

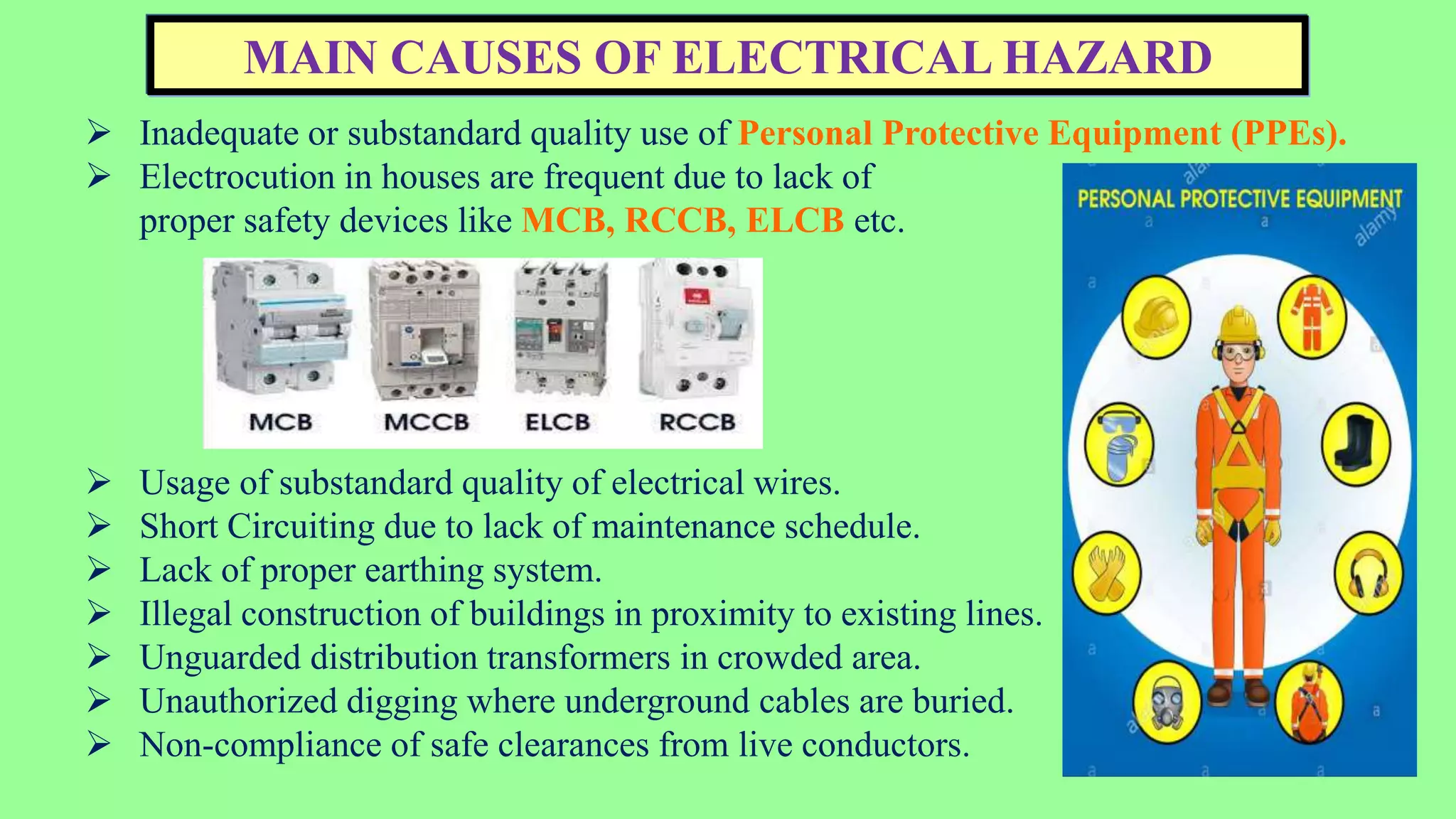

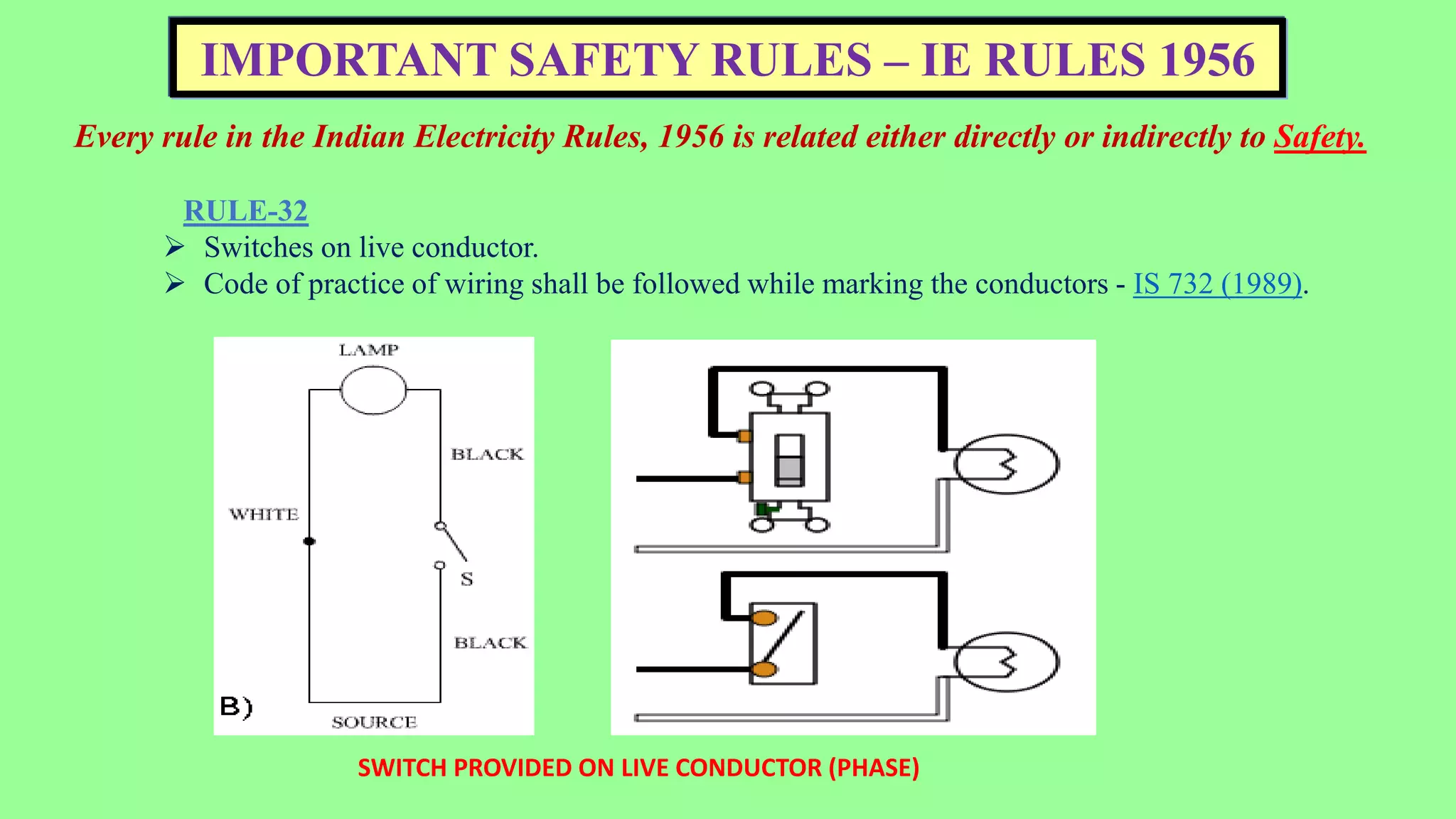

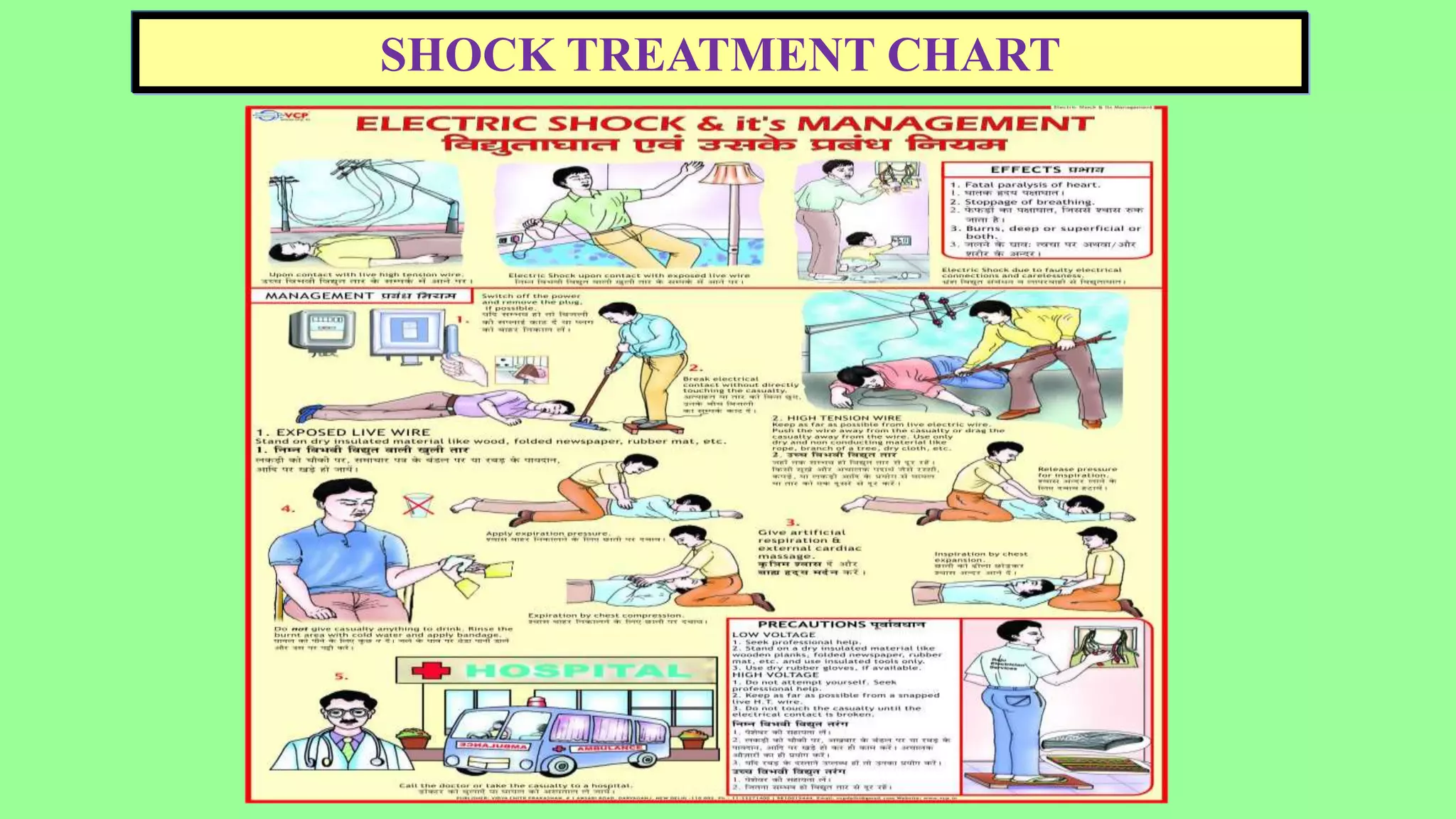

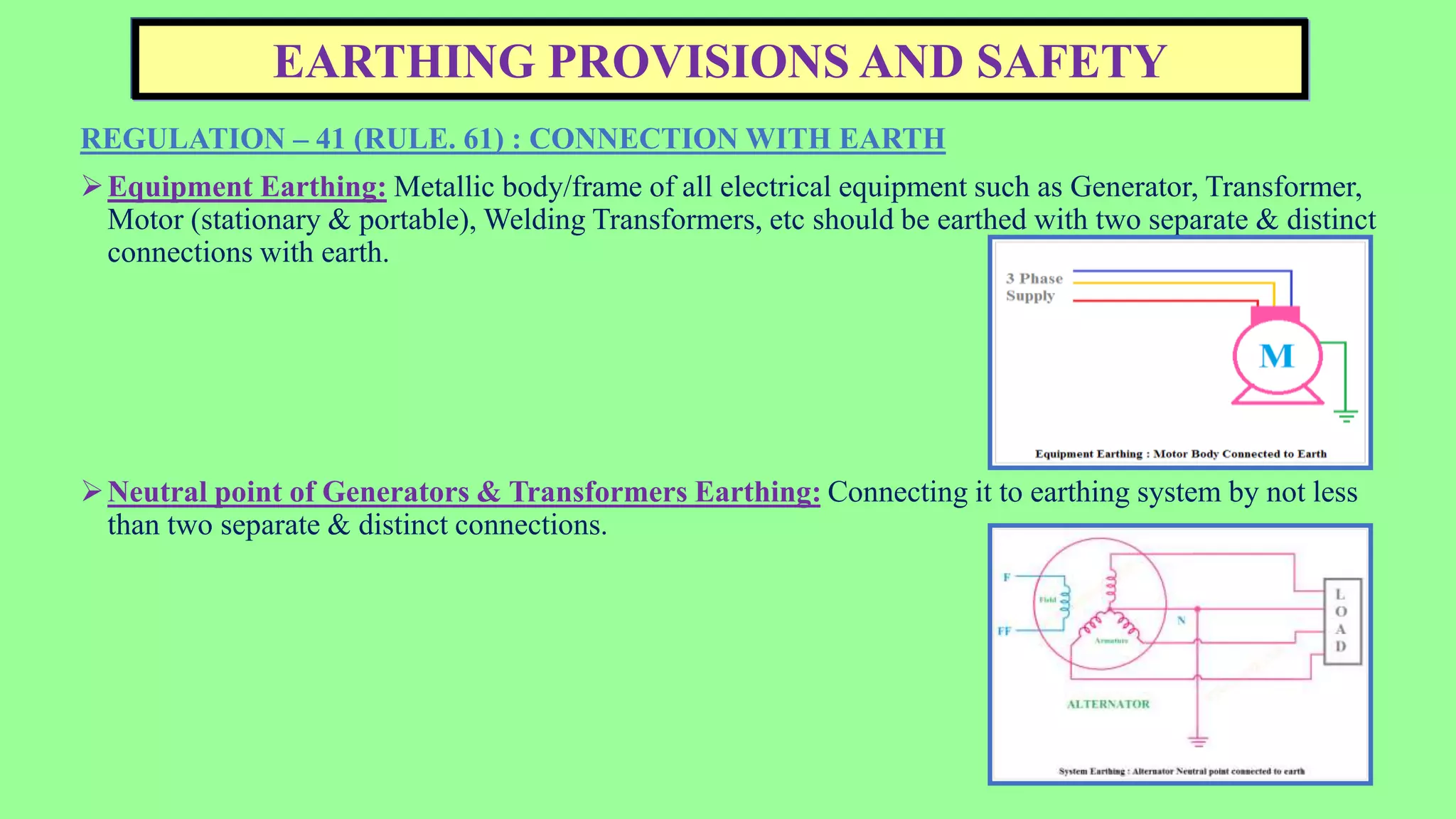

This document discusses electrical safety and provides guidelines on proper safety practices around electricity. It notes that electrocution kills nearly 30 Indians daily, with the highest number of cases among people aged 21-30. Failure to take safety precautions with electricity can cause injury or property damage. Common injuries include electric shocks and burns. The document outlines voltage ranges and the effects of electric current on the human body. It identifies main causes of electrical hazards like lack of protective equipment, earthing, and maintenance. Key safety rules from the Indian Electricity Rules of 1956 are highlighted regarding switches, danger notices, and provisions for high voltage installations. The Central Electricity Authority regulates electrical safety measures in India. The document emphasizes both human safety practices and ensuring