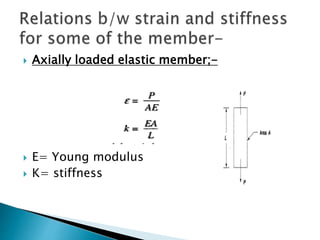

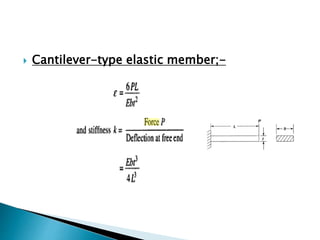

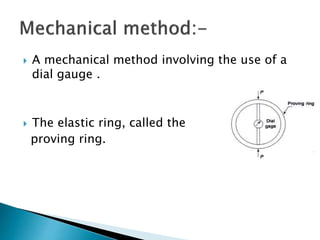

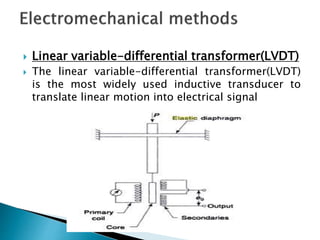

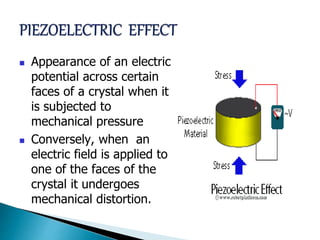

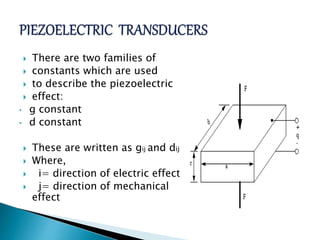

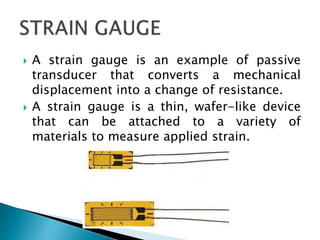

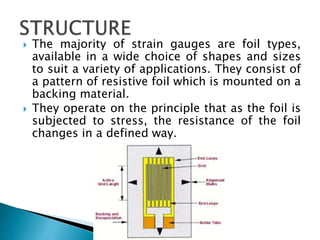

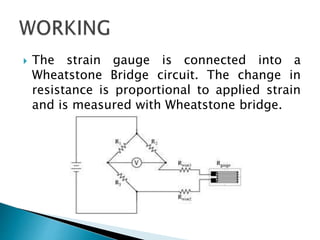

Force transducers use elastic members where applied forces cause displacement or strain that is sensed mechanically or electrically. Common types are axially loaded elastic members and cantilever-type elastic members. Measurement methods include mechanical dial gauges, linear variable differential transformers (LVDTs), piezoelectric transducers, and resistance strain gauges. LVDTs and strain gauges are widely used as they can measure small displacements or strains electrically with high sensitivity and repeatability. Piezoelectric transducers generate electric charges when subjected to mechanical stress.