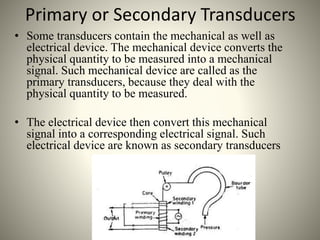

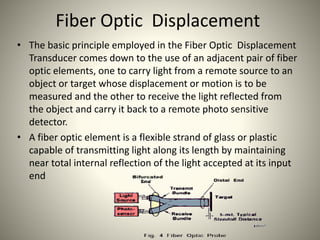

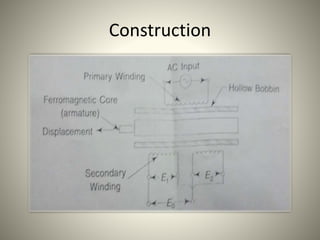

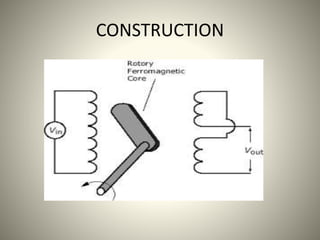

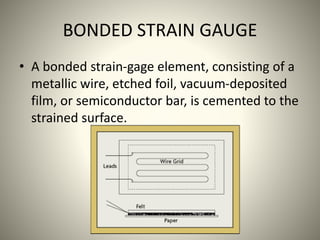

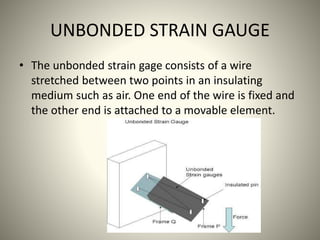

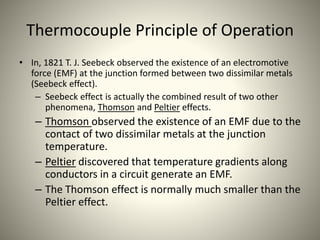

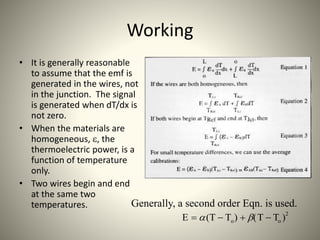

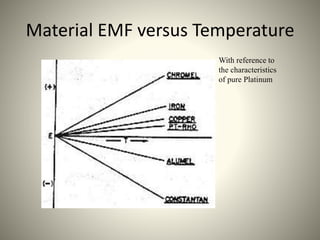

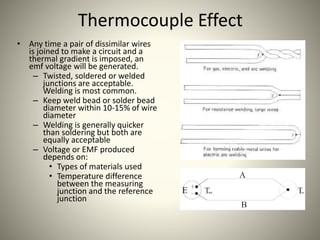

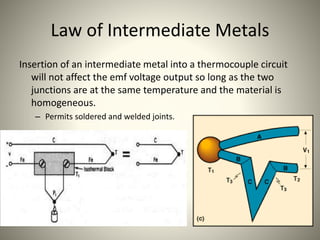

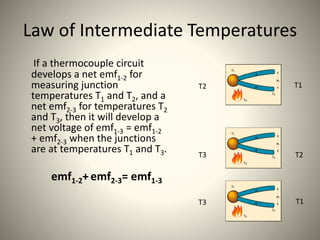

The document provides an in-depth overview of transducers, defining their purpose as devices that convert various forms of energy including mechanical, electrical, and thermal. It classifies transducers into categories such as active and passive, analog and digital, and explains different types like capacitive, electromagnetic, and piezoelectric transducers in terms of their principles and characteristics. Additionally, it discusses applications, measurement techniques, and specific devices like the LVDT and thermocouples, highlighting their advantages and disadvantages.