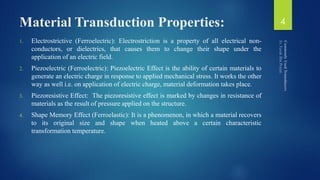

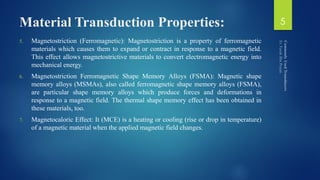

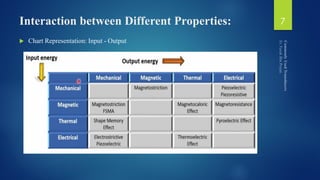

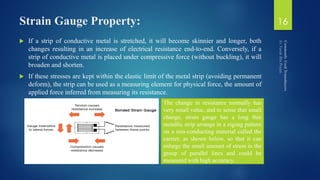

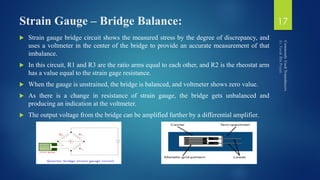

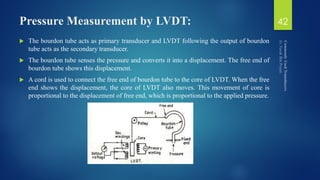

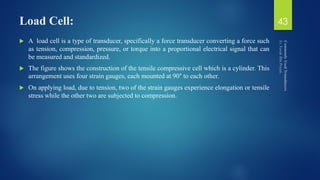

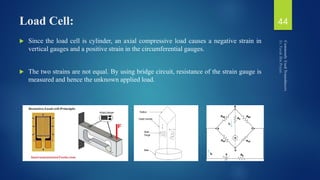

The document discusses various types of transducers used in electrical and electronic measurement, detailing their material properties, operational principles, and applications. It categorizes transducers as active or passive, with examples like strain gauges, potentiometers, and LVDTs, and provides insights into their working mechanisms. Key material properties such as piezoelectric effect, thermoelectric effect, and magnetostriction are also explained, along with their relevance in transducer functionality.