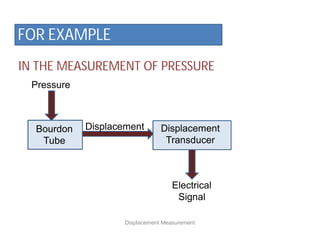

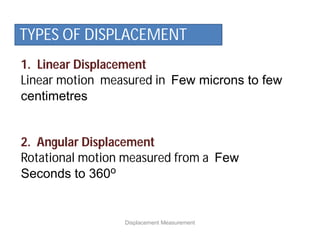

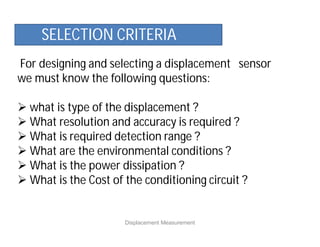

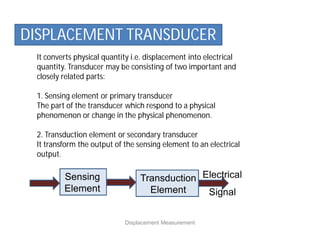

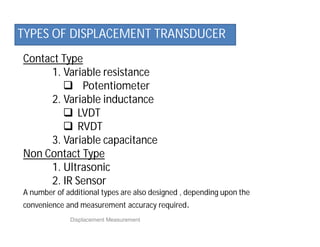

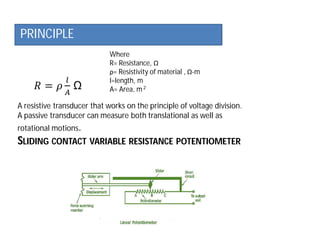

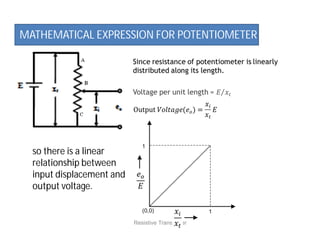

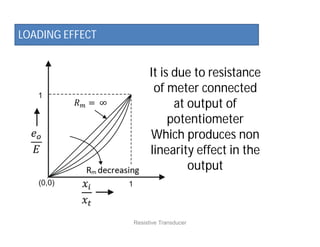

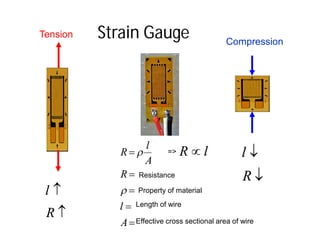

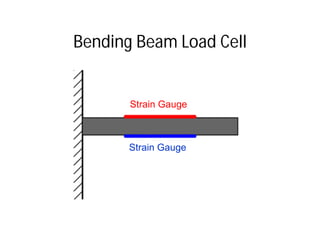

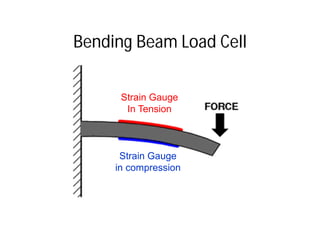

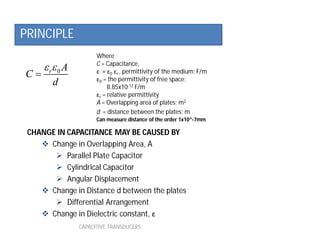

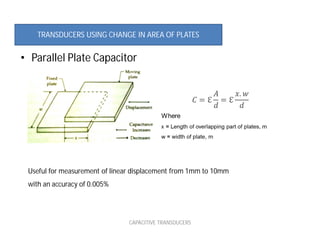

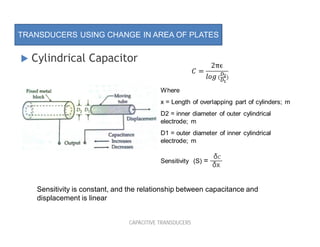

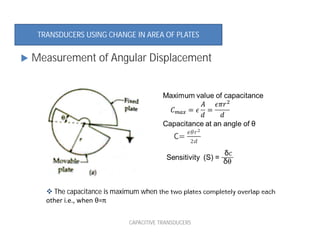

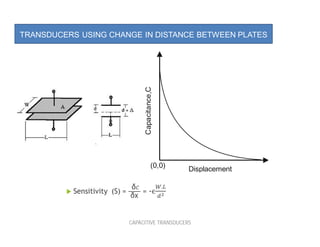

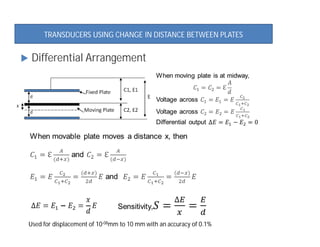

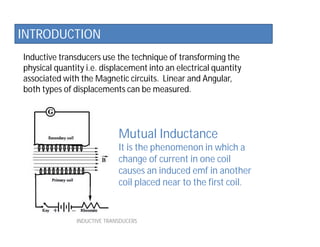

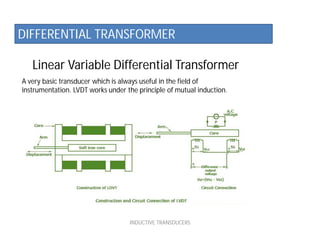

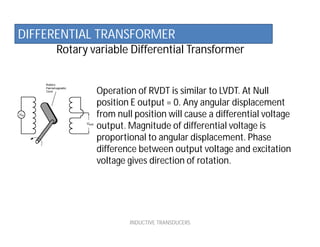

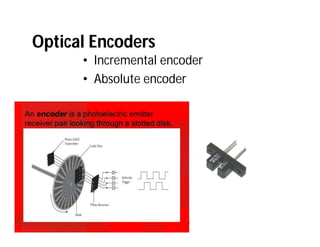

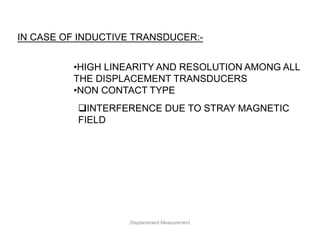

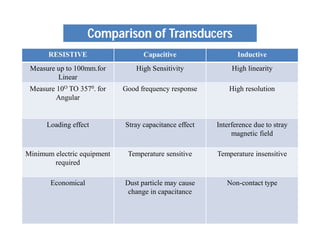

The document provides an overview of displacement measurement, including its definition, types, and transducer selection criteria. It discusses various types of displacement transducers, such as resistive, capacitive, and inductive, each with their advantages and disadvantages. The importance of understanding the measurement requirements and the characteristics of different transducers is emphasized for effective application in instrumentation.