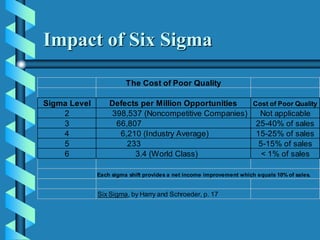

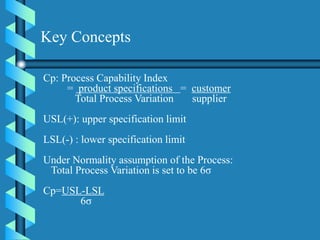

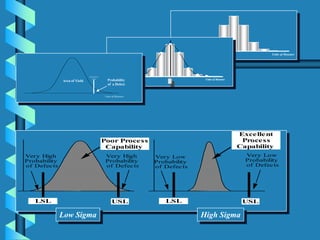

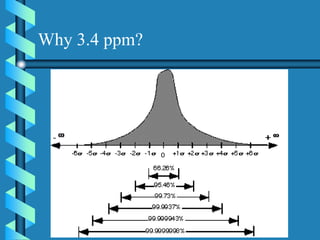

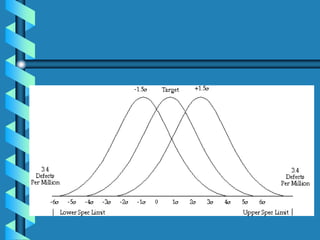

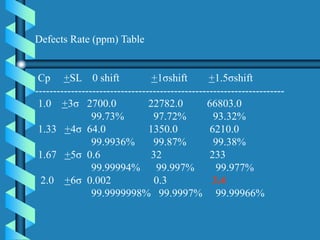

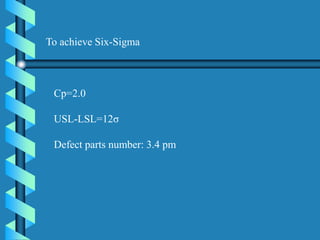

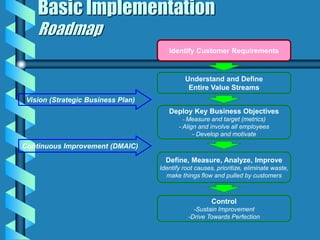

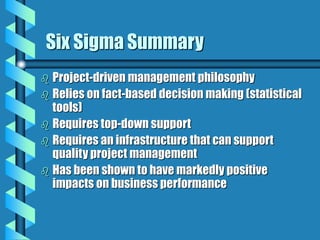

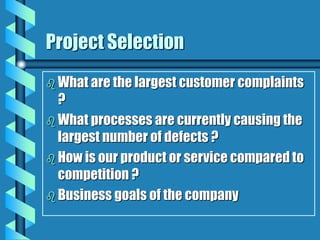

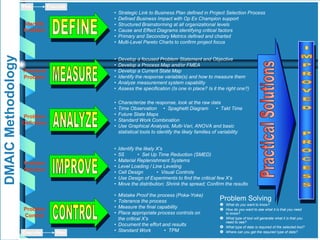

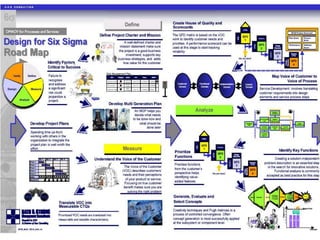

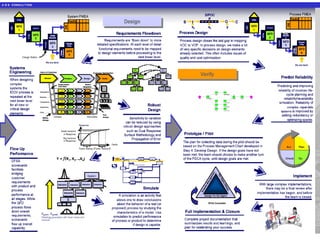

Six Sigma is a data-driven approach to process improvement that aims to reduce defects. It was introduced by Motorola in 1987 and involves defining, measuring, analyzing, improving, and controlling processes to minimize errors. The goal of Six Sigma is to operate processes with as close to zero defects as possible by reducing process variation. A Six Sigma process is one that produces only 3.4 defects per million opportunities. Key aspects include using statistical tools and methodologies, such as DMAIC, to systematically identify and remove sources of errors and variation in order to improve quality, lower costs, and increase customer satisfaction.