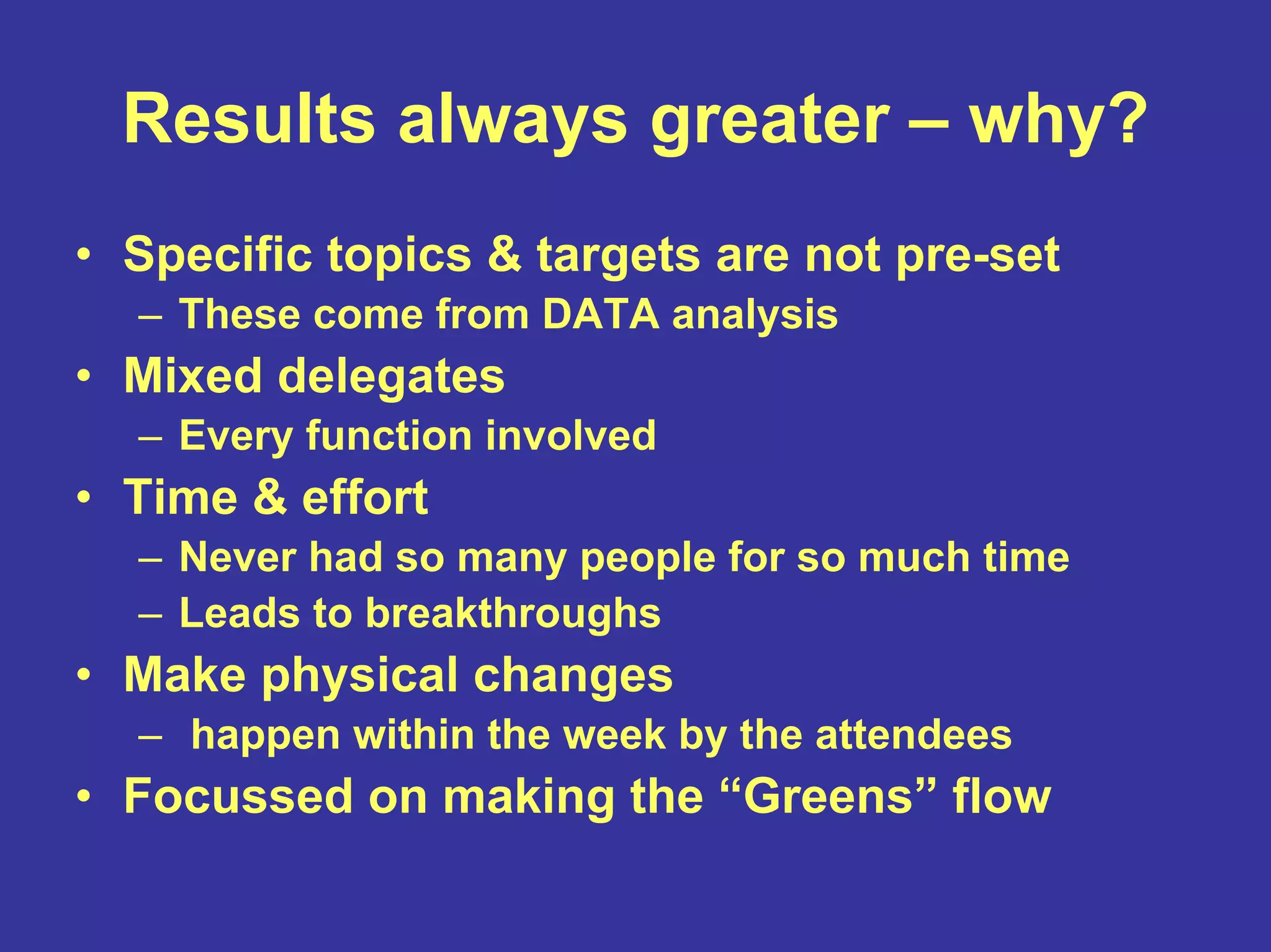

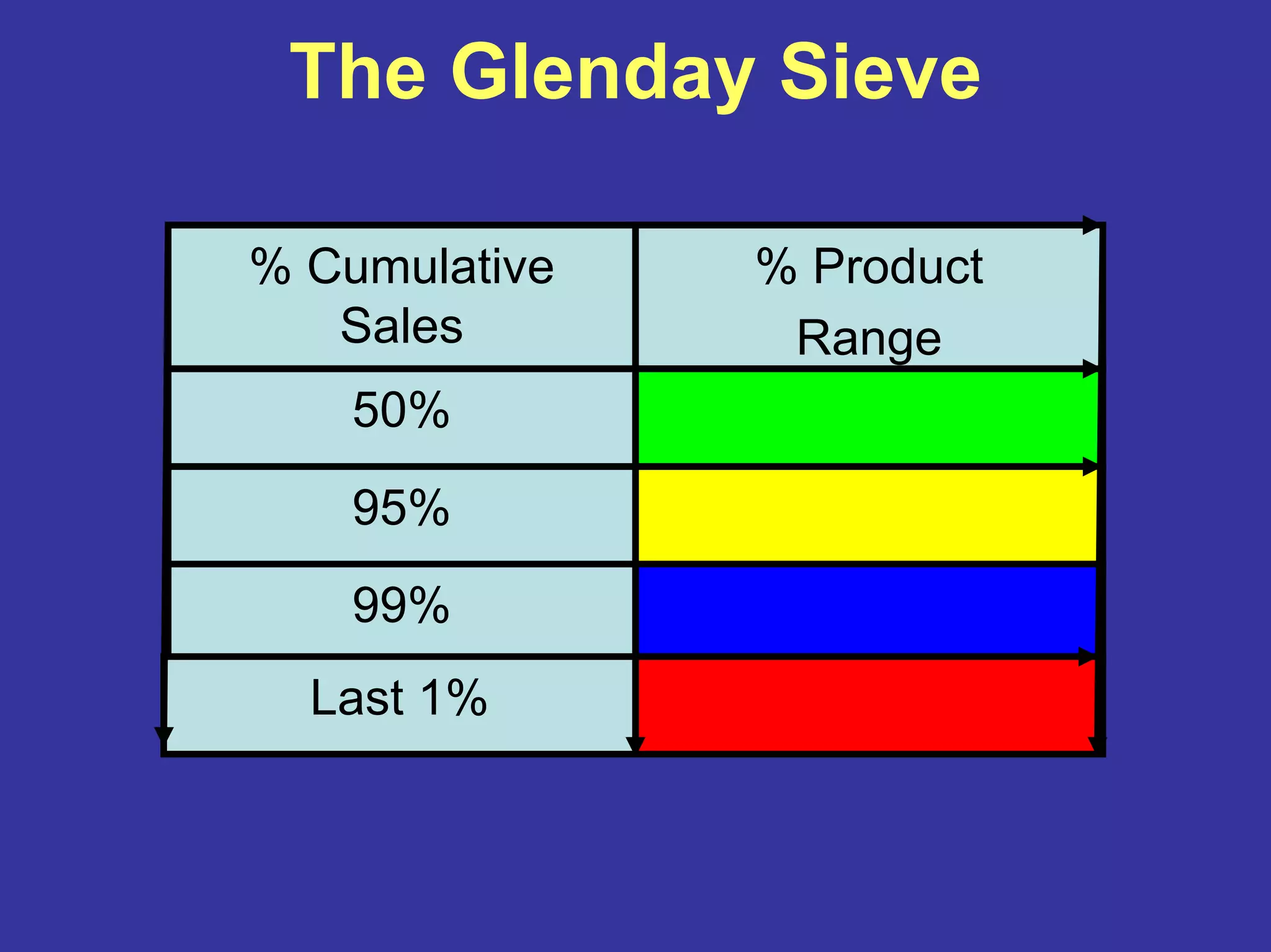

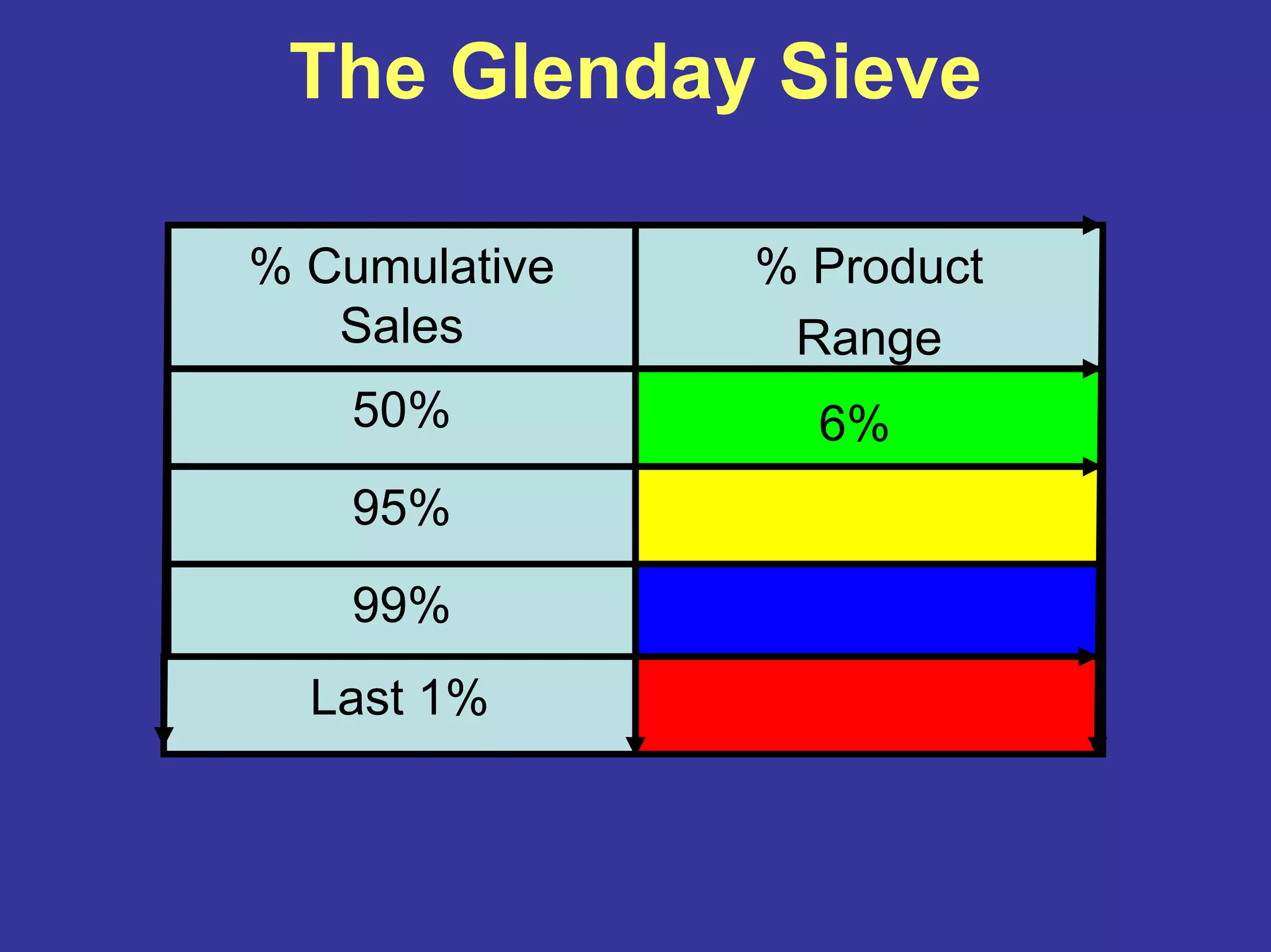

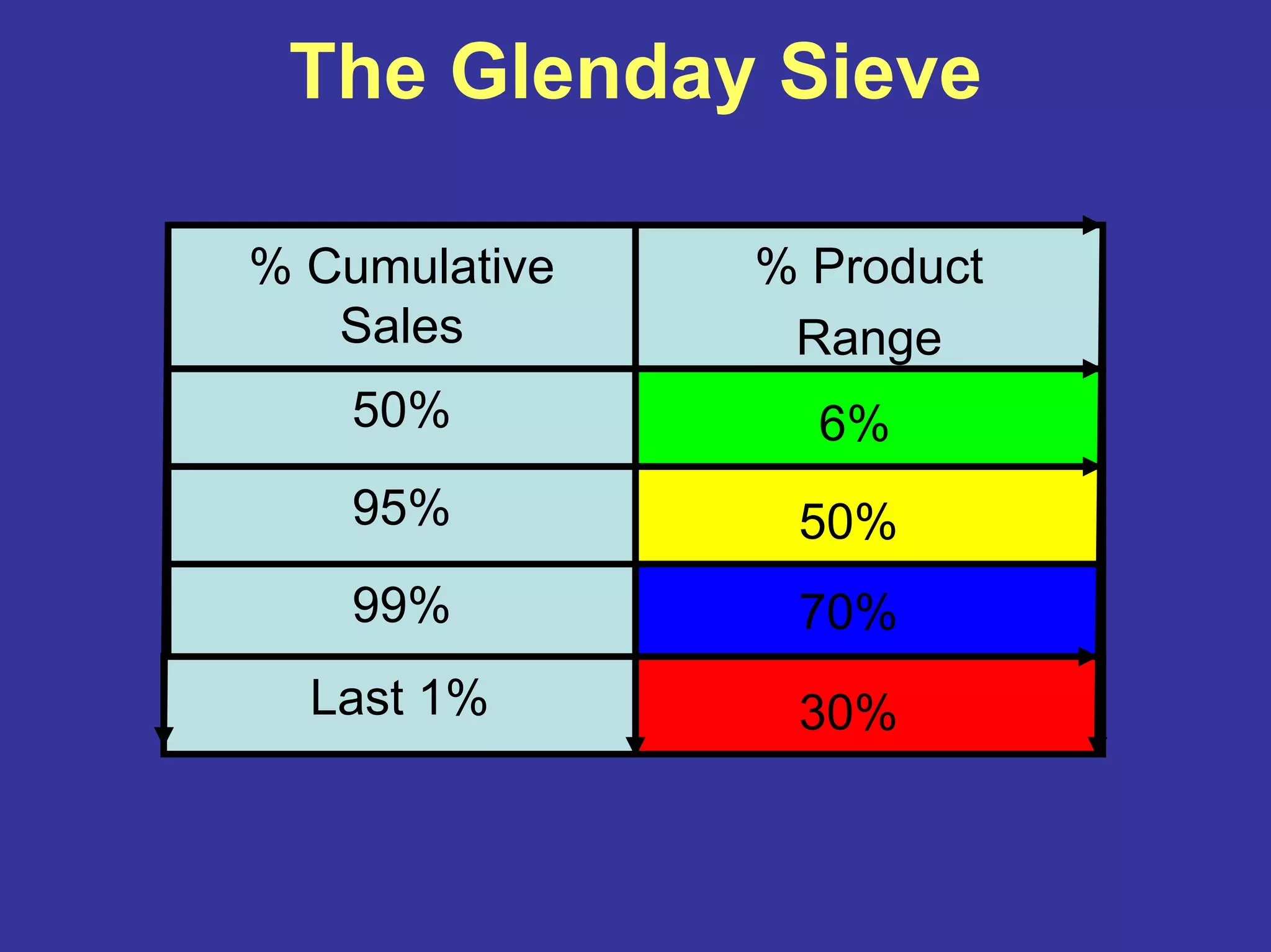

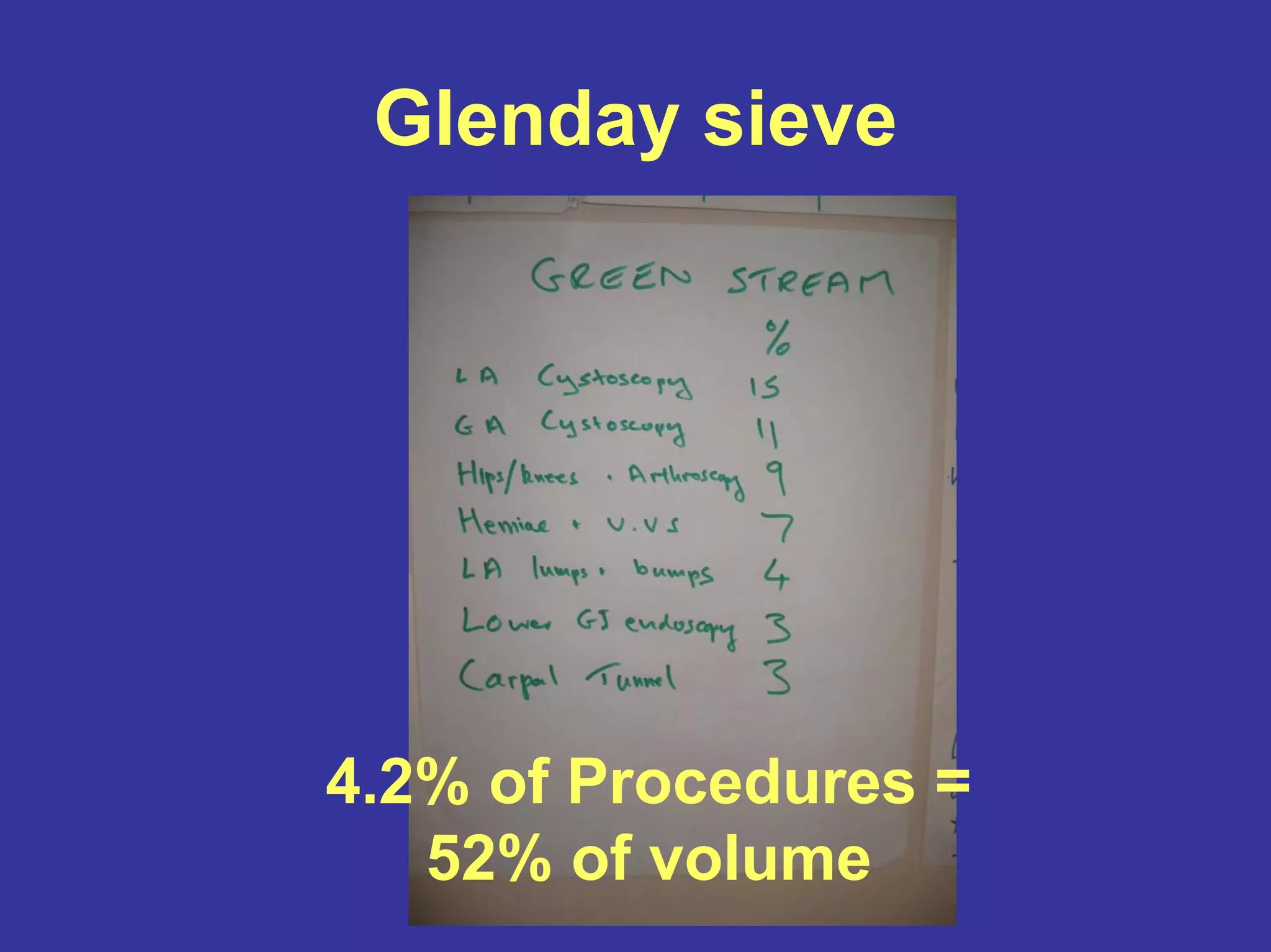

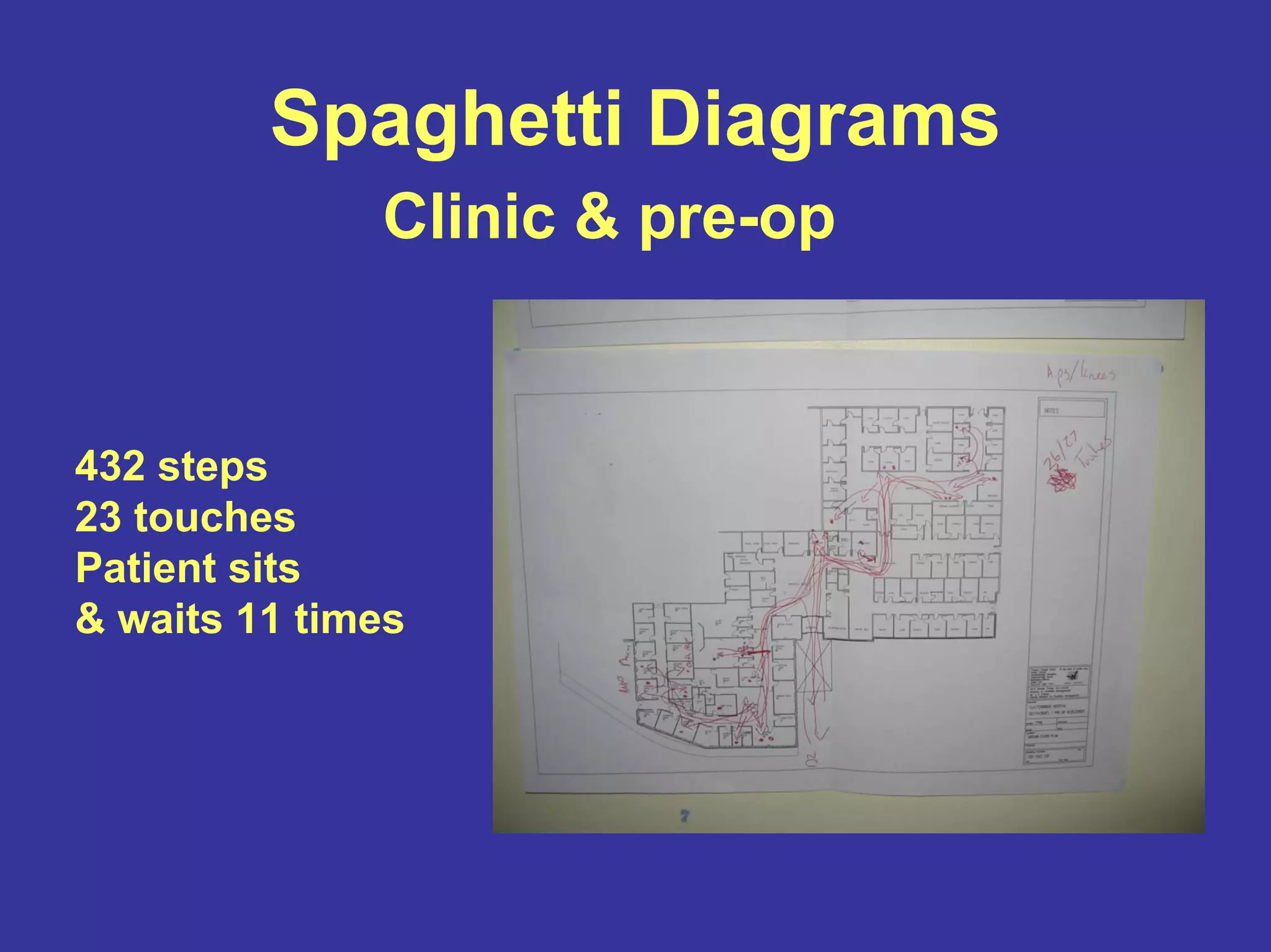

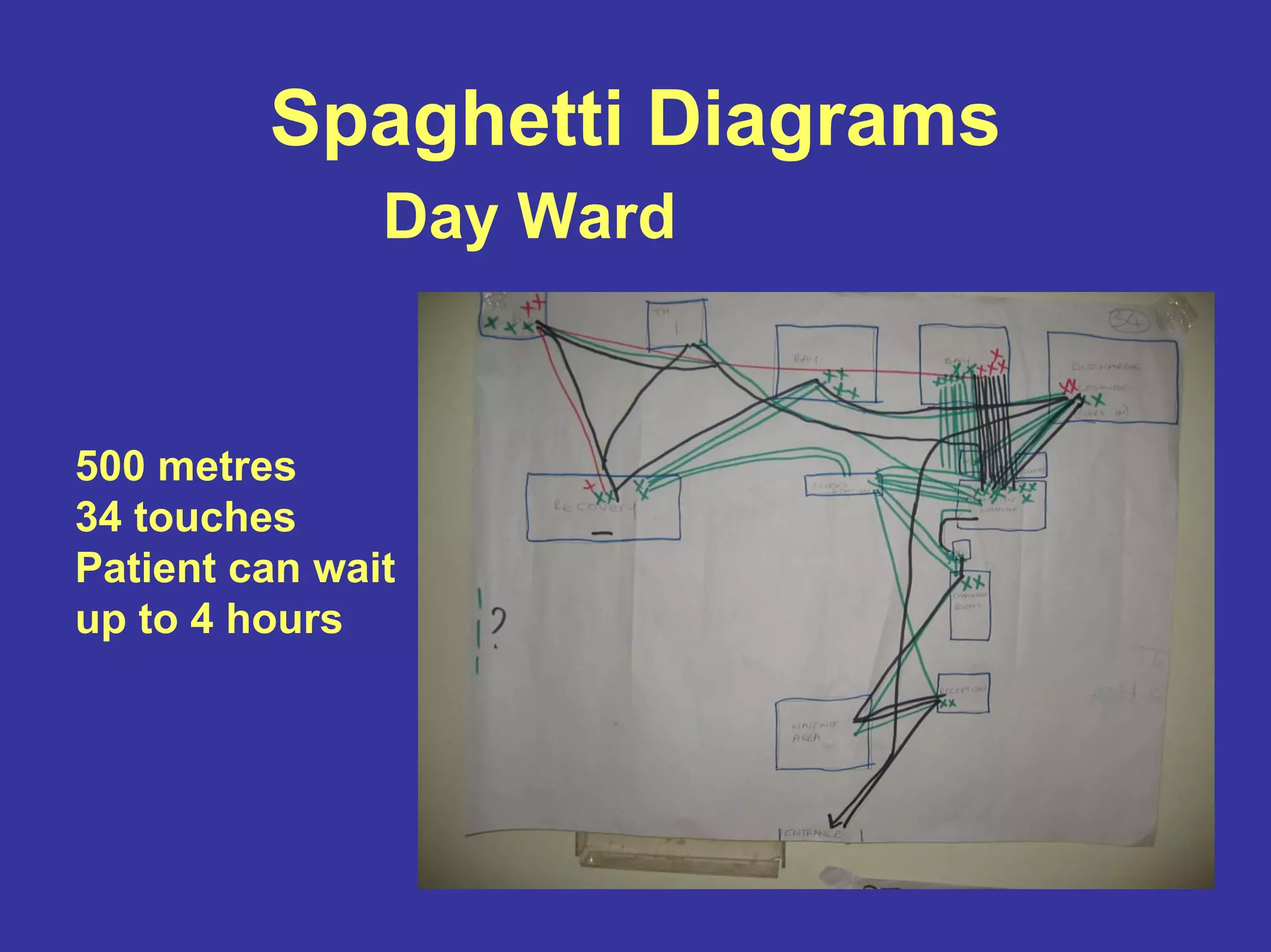

The document outlines the structure and principles of running rapid improvement events (kaizen workshops) aimed at creating flow in value streams and eliminating waste. It describes the process over five days, focusing on analysis, setting objectives, and tangible improvements involving mixed teams, with specific tools like the Glenday sieve and value stream mapping to guide the analysis. Results are often significantly better than expected due to thorough analysis, diverse participation, and collaborative work environment.