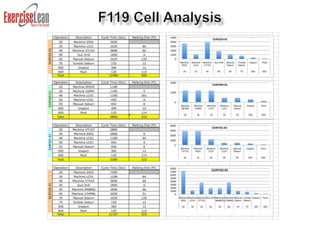

This document summarizes an analysis of cell F119. It identifies four part numbers processed in the cell with travel times. It also lists some manufacturing processes occurring in the cell like lathe and mill. The document recommends reorganizing the cell layout to reduce travel times and balance work content. A rapid assessment was conducted on the cell over three days reviewing processes, defining value-added vs. non-value added work, and developing a future state map and new layout with an U-shape to reduce waste. An action plan was created to implement the changes.