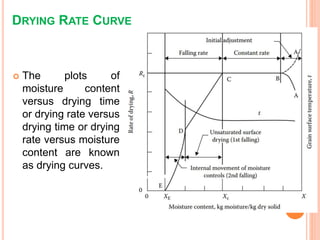

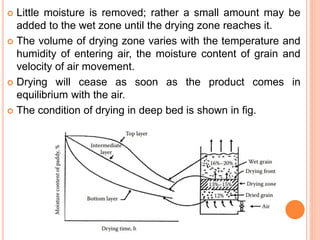

Drying removes moisture from agricultural products to allow for safe storage. There are two main drying periods - a constant rate period where drying is dependent on conditions like temperature/humidity differences, and a falling rate period where moisture moves more slowly within the product. Drying curves plot moisture content or drying rate over time/moisture content. Thermal properties like specific heat and thermal conductivity also impact drying. Drying can occur in thin layers, with full air exposure, or in deep beds with changing internal conditions.