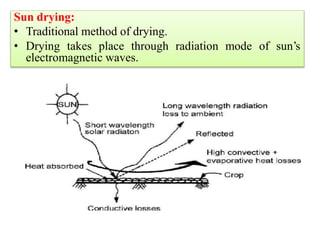

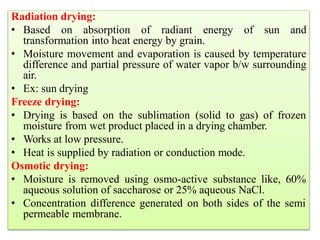

Drying grains is important to allow for safe long-term storage by reducing moisture content to prevent spoilage. There are various drying methods like sun drying, convection drying using hot air or gases, and radiation drying using electromagnetic waves. Common dryers include flat bed dryers, mechanical tray dryers, and solar dryers which utilize the sun's energy. Proper drying is necessary to retain nutrients while sufficiently lowering moisture for storage.