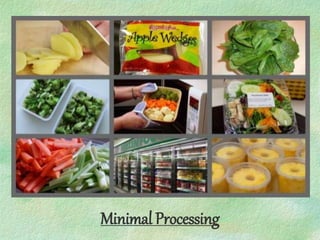

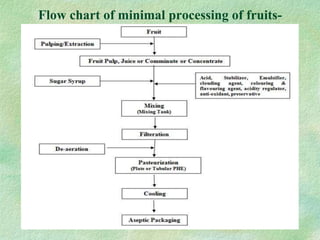

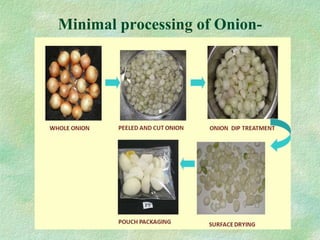

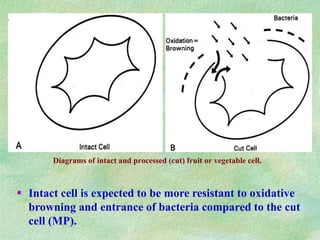

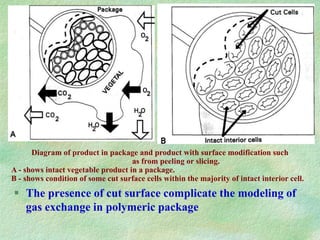

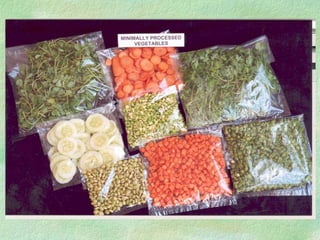

Minimal processing refers to lightly processing fruits and vegetables through operations like trimming, peeling, slicing, and coring that preserve the quality while extending the shelf life. This processing approach has grown in demand due to consumer preferences for convenience, healthfulness, and products containing few additives. However, the cut surfaces exposed through minimal processing can cause physiological and biochemical changes like increased respiration and enzymatic browning as well as microbial spoilage. Controlling these quality deterioration factors is important for maintaining the fresh-like characteristics of minimally processed produce.