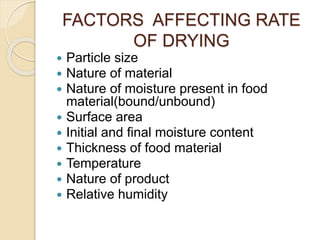

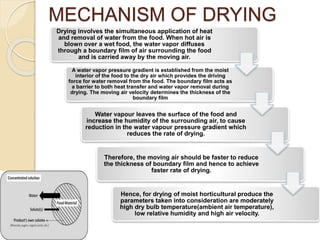

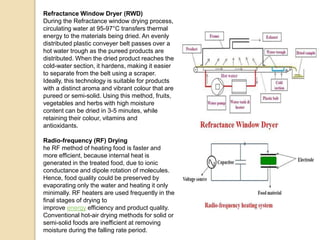

The document discusses advancements in food processing and preservation techniques, particularly focusing on drying and dehydration methods. It highlights the differences between drying and dehydration, the benefits of drying, factors that affect drying rates, and the mechanisms involved. Recent innovations like heat pump drying, microwave drying, and freeze drying are also examined, emphasizing their role in improving quality and efficiency in food preservation.