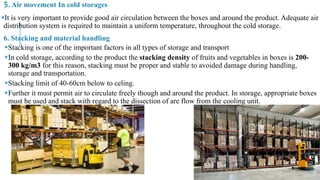

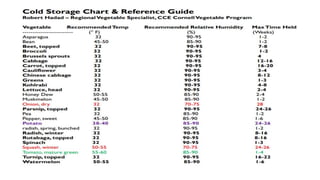

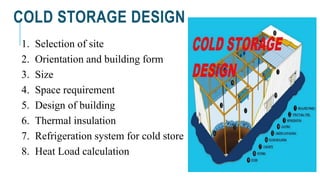

Cold storage facilities store perishable foods at controlled temperatures to extend their shelf life. They range from +10°C to -20°C, with different temperature requirements for different products like ice cream, milk, fruits and vegetables. Cold storage allows food to be stored when plentiful and used when scarce, facilitates transportation, and reduces food spoilage and costs. Proper temperature, humidity, sanitation and air circulation are needed to safely store foods in cold storage.