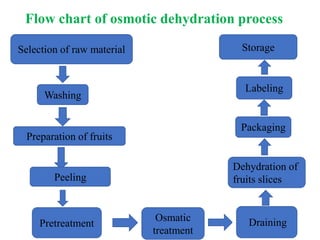

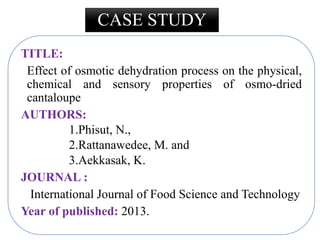

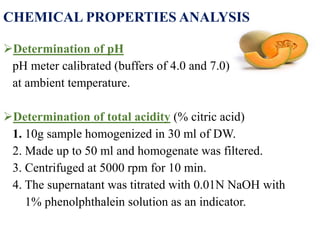

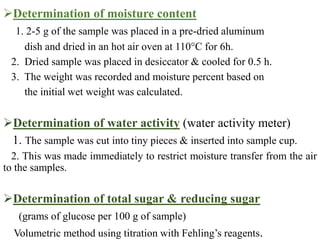

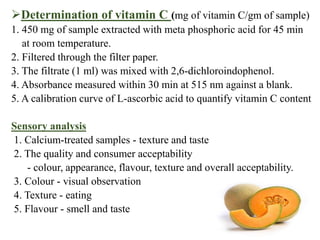

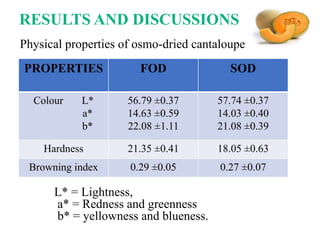

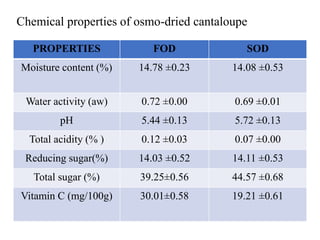

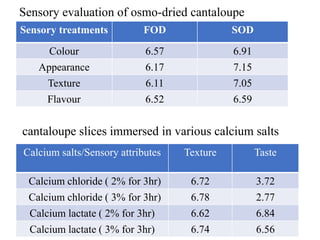

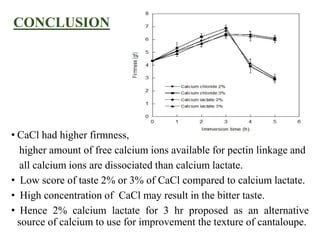

This document summarizes a study on the osmotic dehydration of cantaloupe. It describes how cantaloupe slices were treated with calcium salts then subjected to either fast or slow osmotic dehydration in sucrose solutions. Analysis found the slow method retained more vitamin C and led to higher sensory ratings. Pretreatment with 2% calcium lactate for 3 hours was found to improve texture without affecting taste. The study demonstrated how osmotic dehydration can influence the physical, chemical, and sensory properties of fruits.