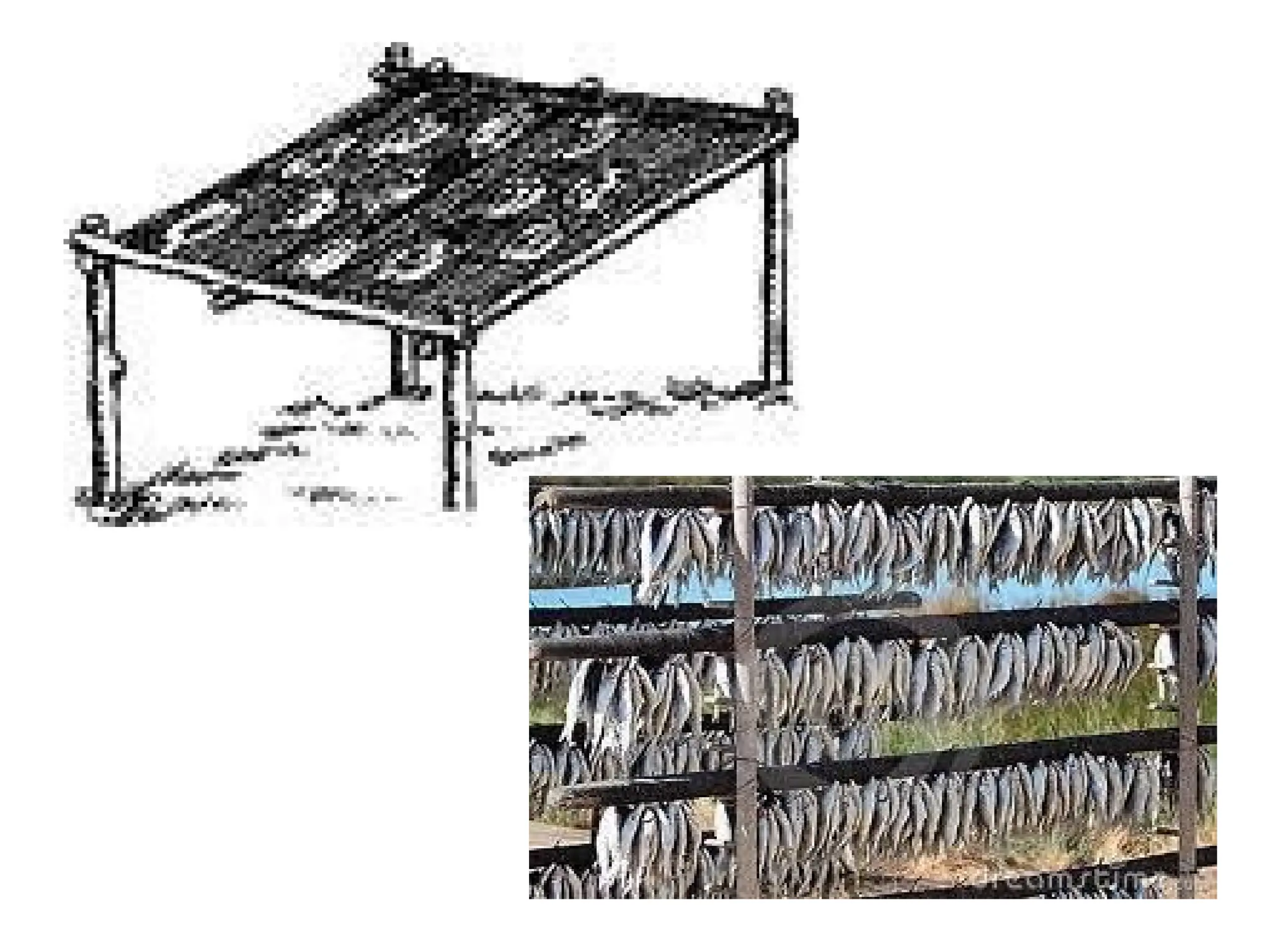

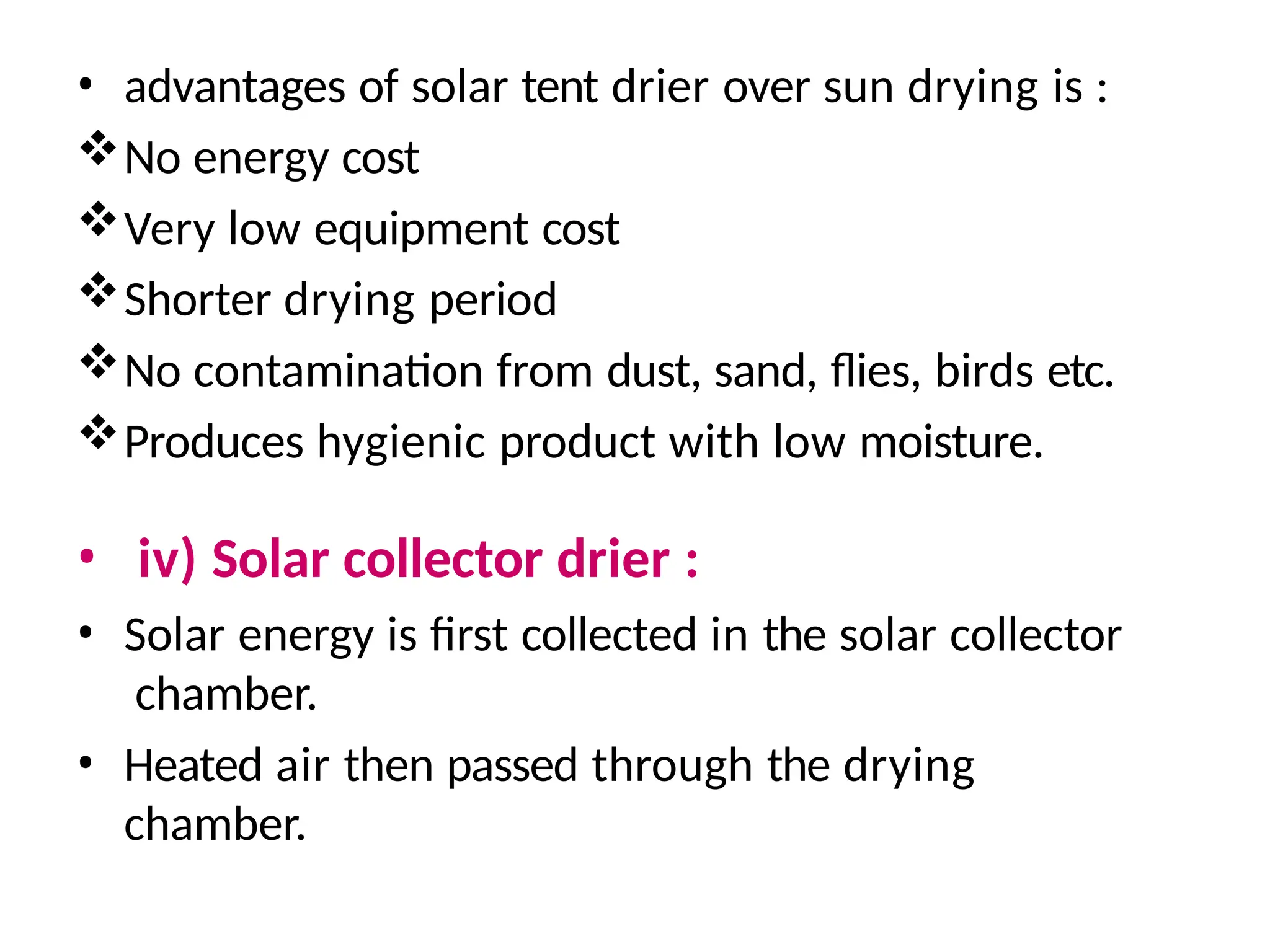

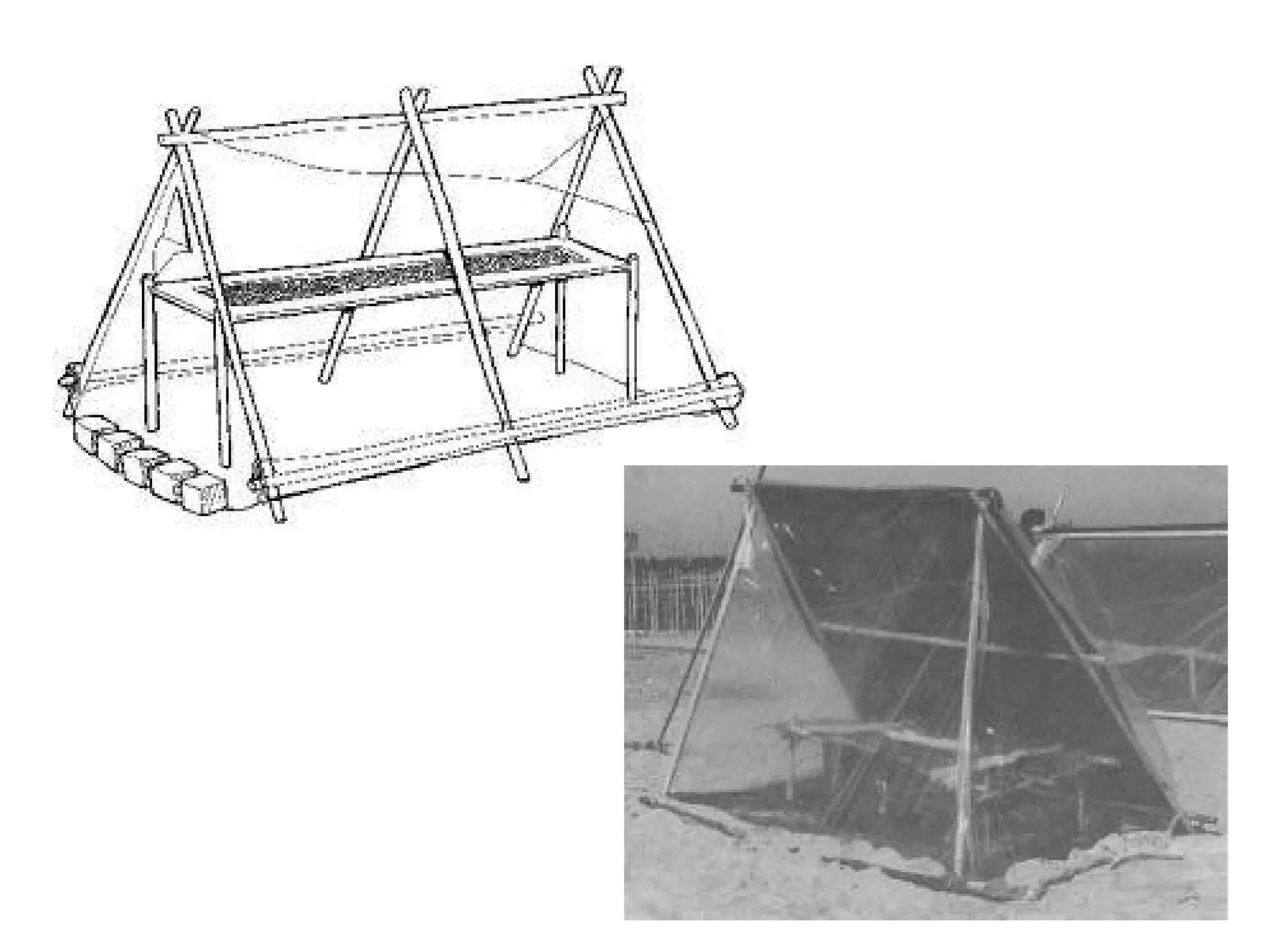

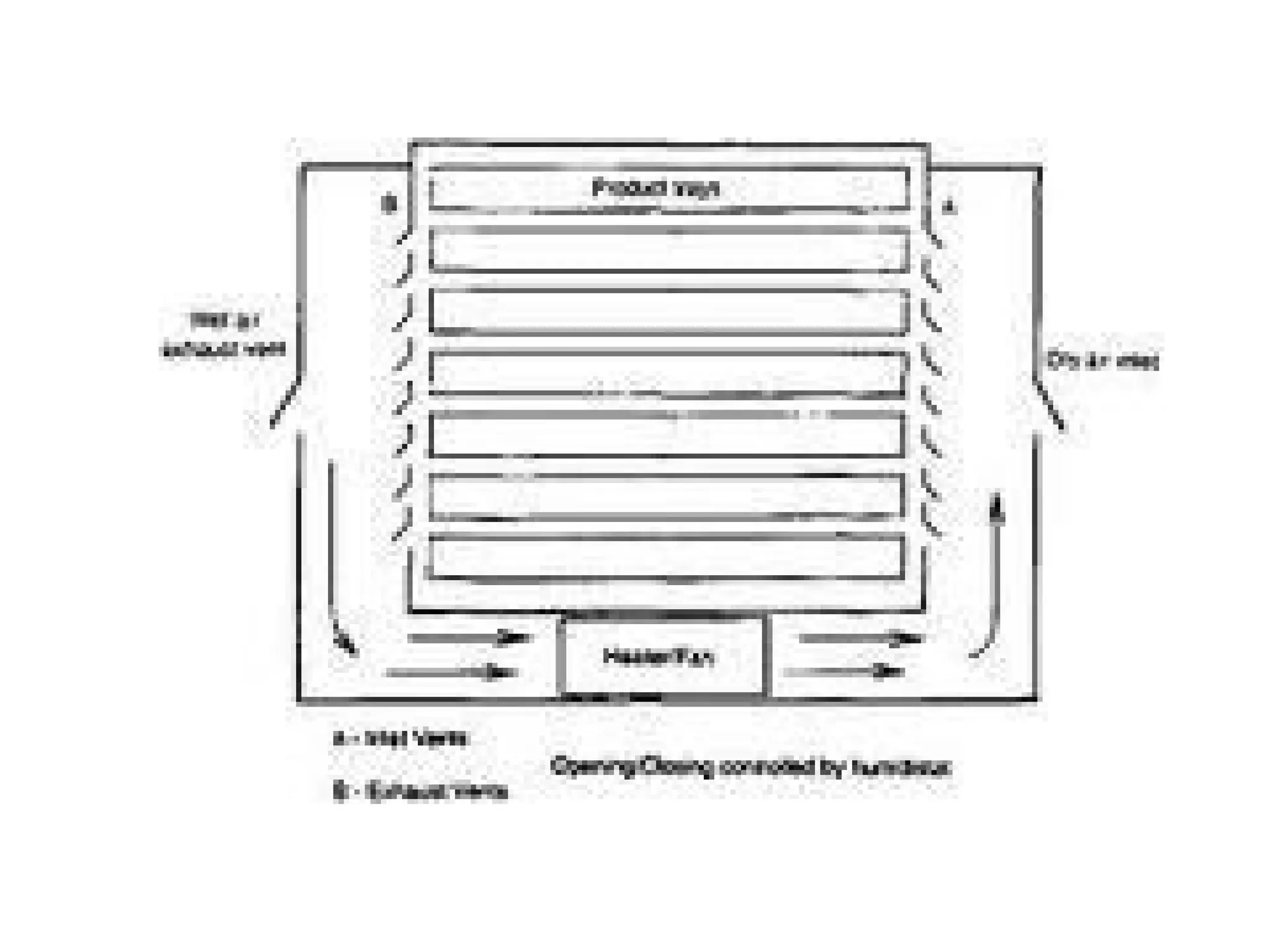

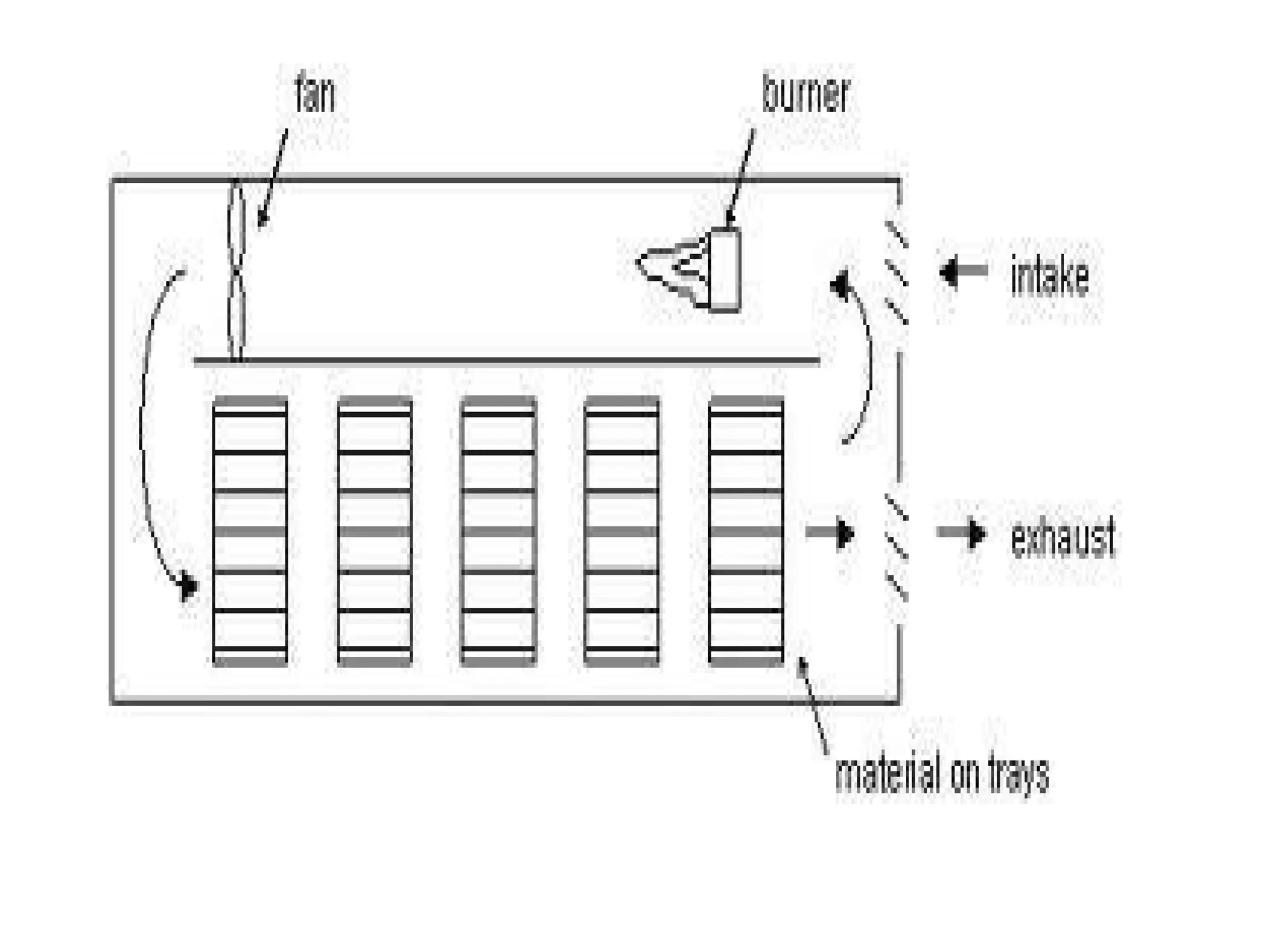

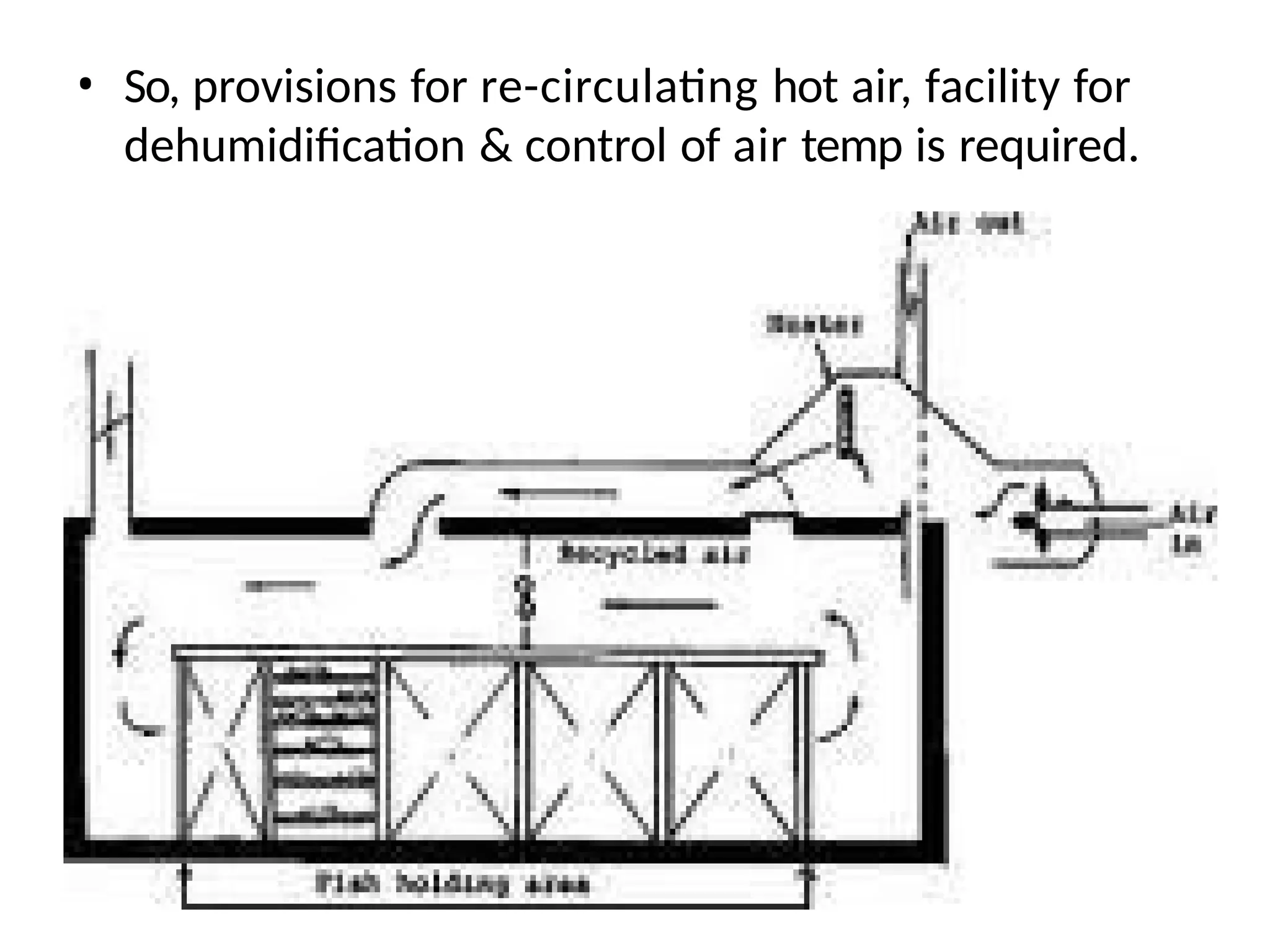

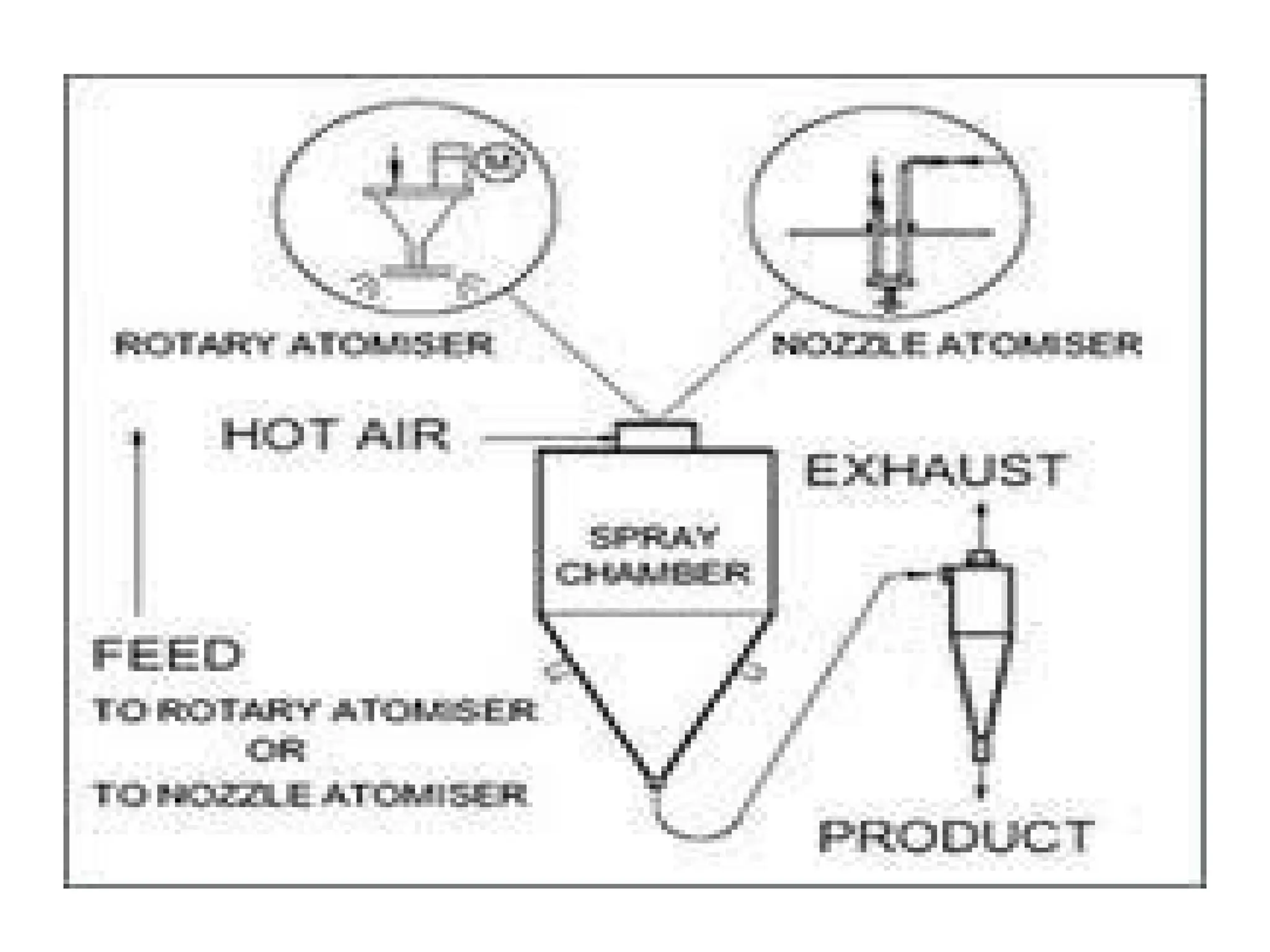

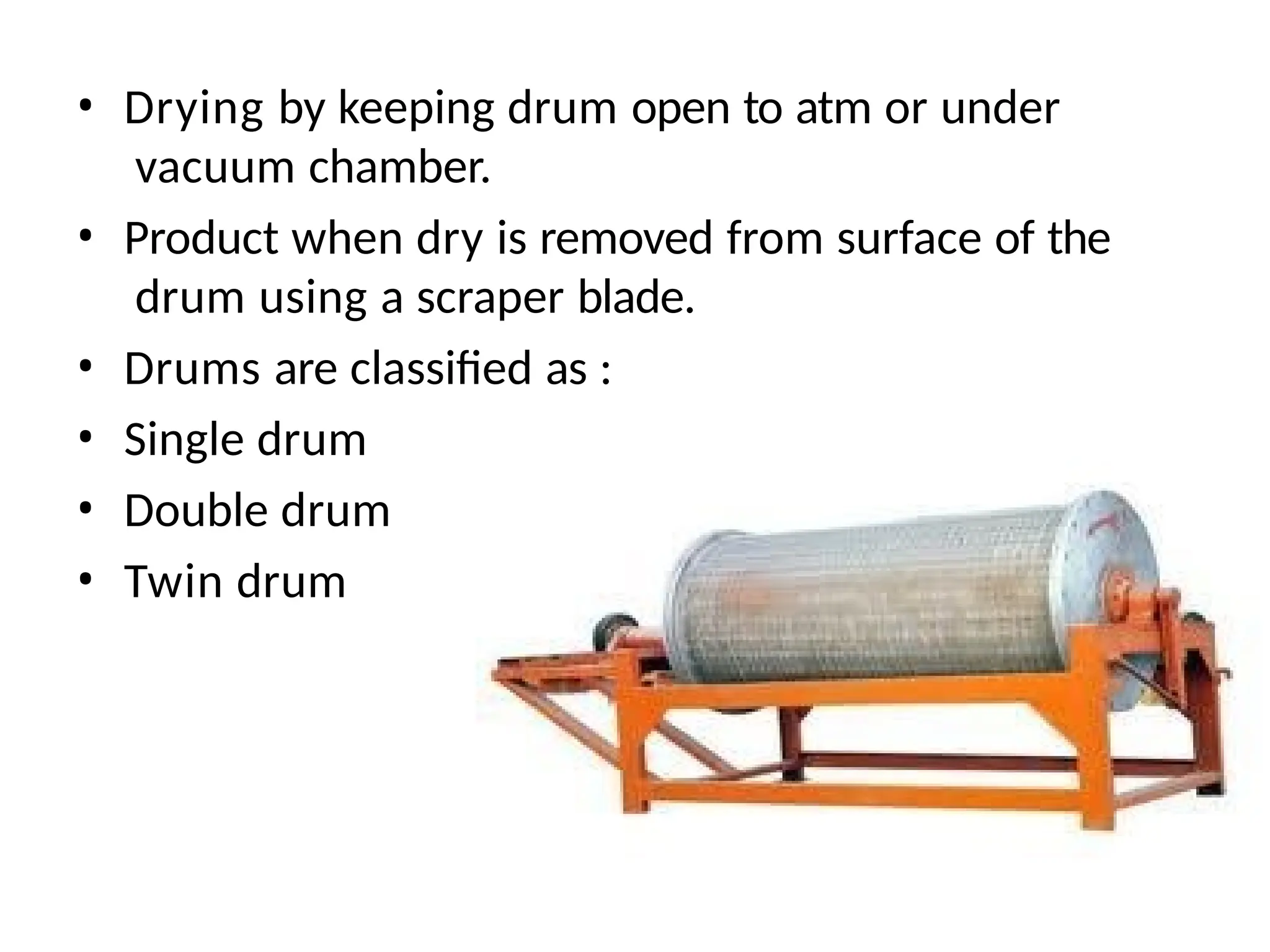

The document outlines various methods of fish drying, including natural methods like sun drying and several artificial techniques such as mechanical dryers. It details the advantages and disadvantages of each method, focusing on factors like temperature control, contamination risks, and product quality. Additionally, it addresses the effects of drying on fish quality, spoilage issues, and packaging concerns to ensure product safety and longevity.