This document provides information about salting and drying of fish and fish meal processing. It discusses:

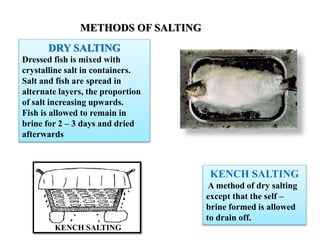

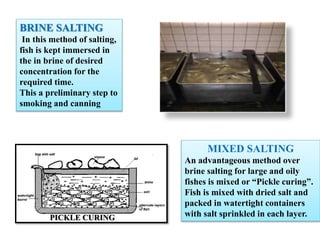

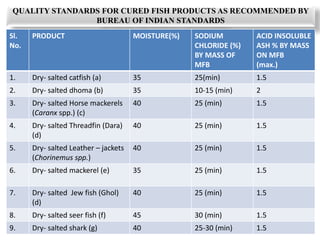

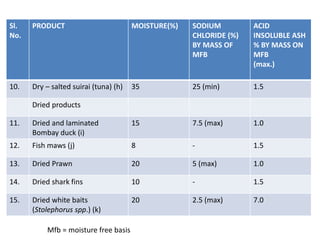

- The theory and methods of salting fish through dry salting, brine salting, and mixed salting.

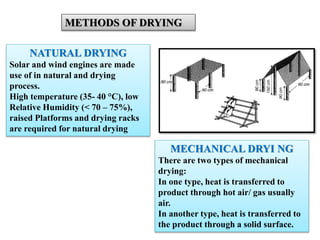

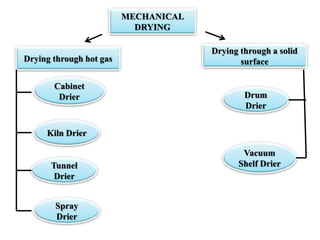

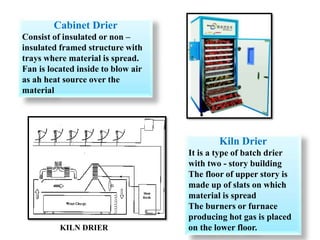

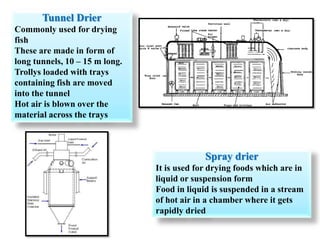

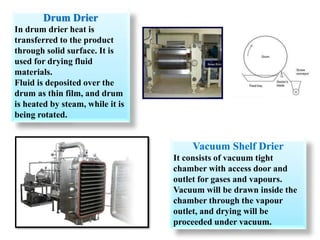

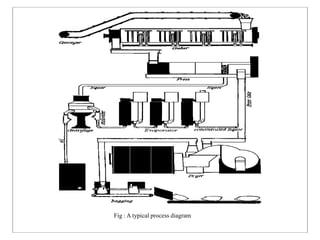

- Methods of drying fish including natural drying, mechanical drying using cabinet driers, kiln driers, tunnel driers, drum driers, and vacuum shelf driers.

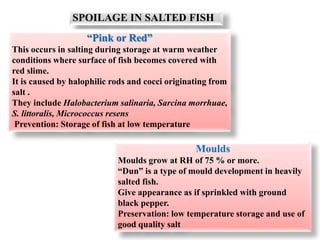

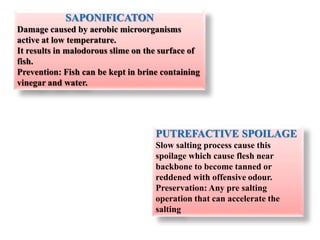

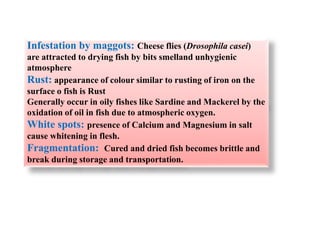

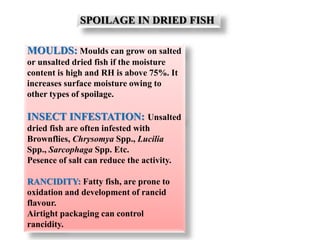

- Potential spoilage issues for salted and dried fish like moulds, insect infestation, and rancidity.

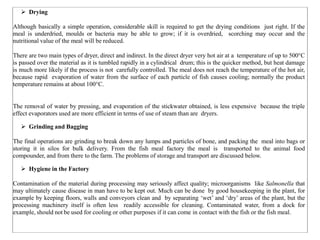

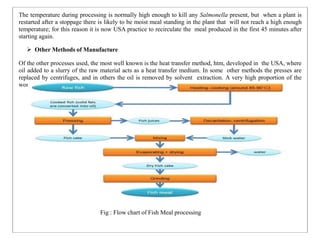

- The process for manufacturing fish meal including cooking, pressing, drying, grinding, and potential risks like spontaneous combustion if not treated with antioxidants.