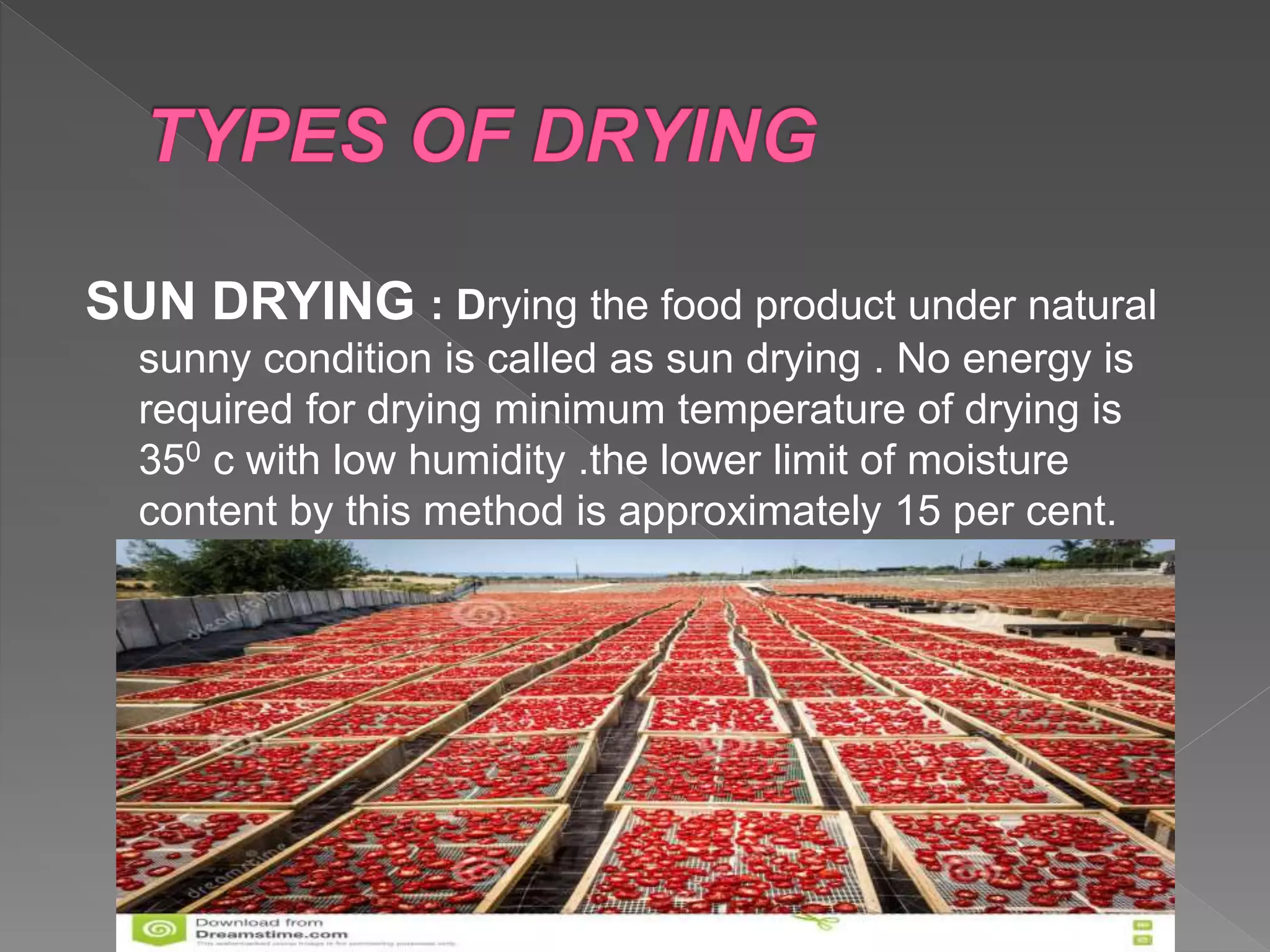

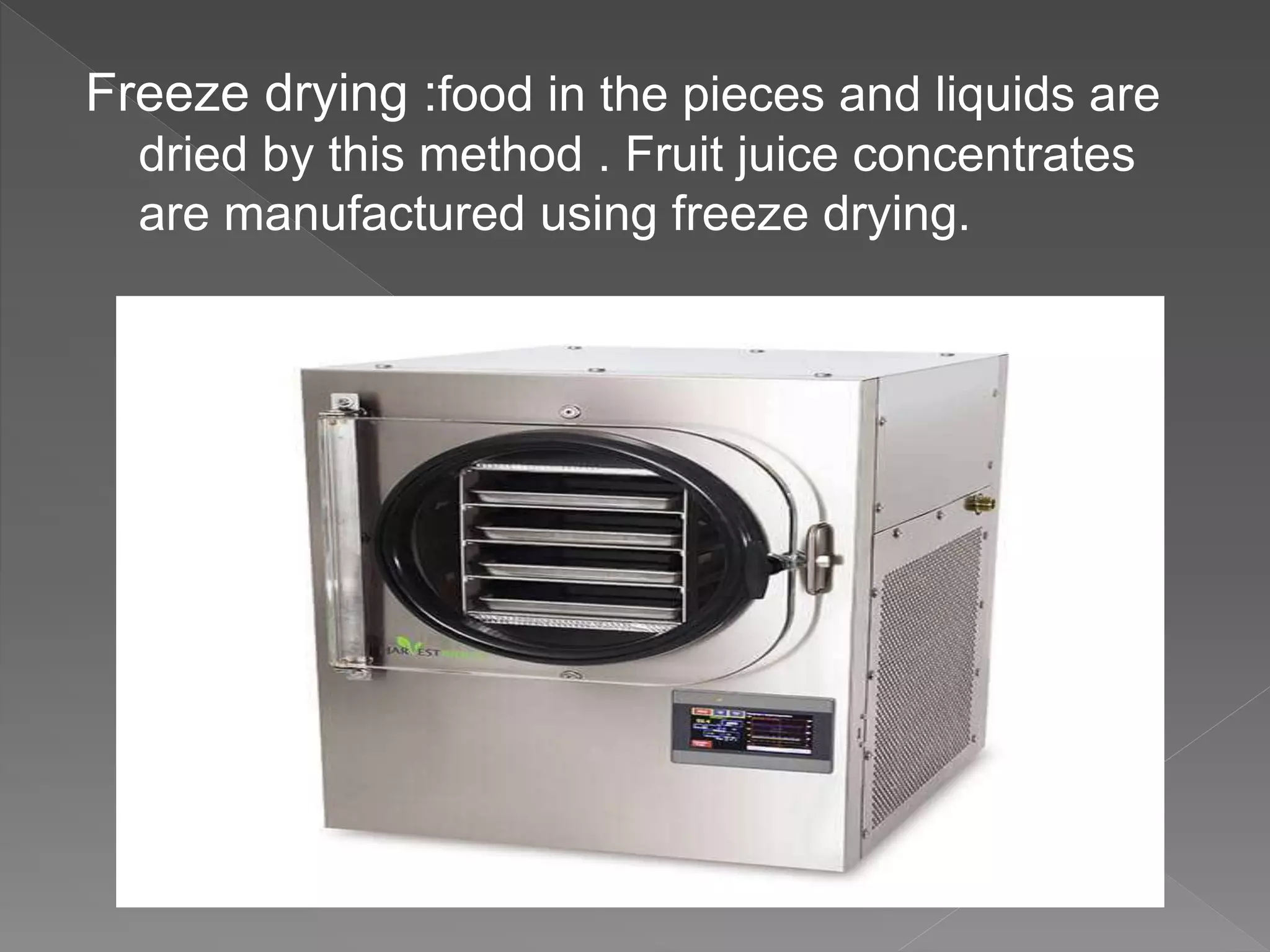

Drying is the oldest method of food preservation and involves reducing the water content of foods to levels low enough to prevent microbial growth. There are several methods of drying foods, including sun drying, solar drying, shade drying, oven drying, drum drying, spray drying, freeze drying and more. Proper drying techniques help retain the nutritional value, flavor and texture of foods. Drying requires controlling factors like temperature, humidity, air velocity and heat transfer during the process.