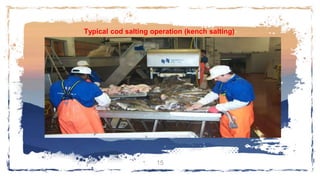

This document discusses salting as a method of food preservation. It describes salting as lowering the moisture content of fish through osmosis to inhibit bacterial and enzymatic activity. The document outlines that salting is usually combined with other preservation methods and discusses factors that affect salt penetration such as fat content, thickness of flesh, and temperature. Common salting methods like dry salting and wet salting are also summarized. Potential spoilage issues from improper salting like pink discoloration and sliminess are also highlighted.