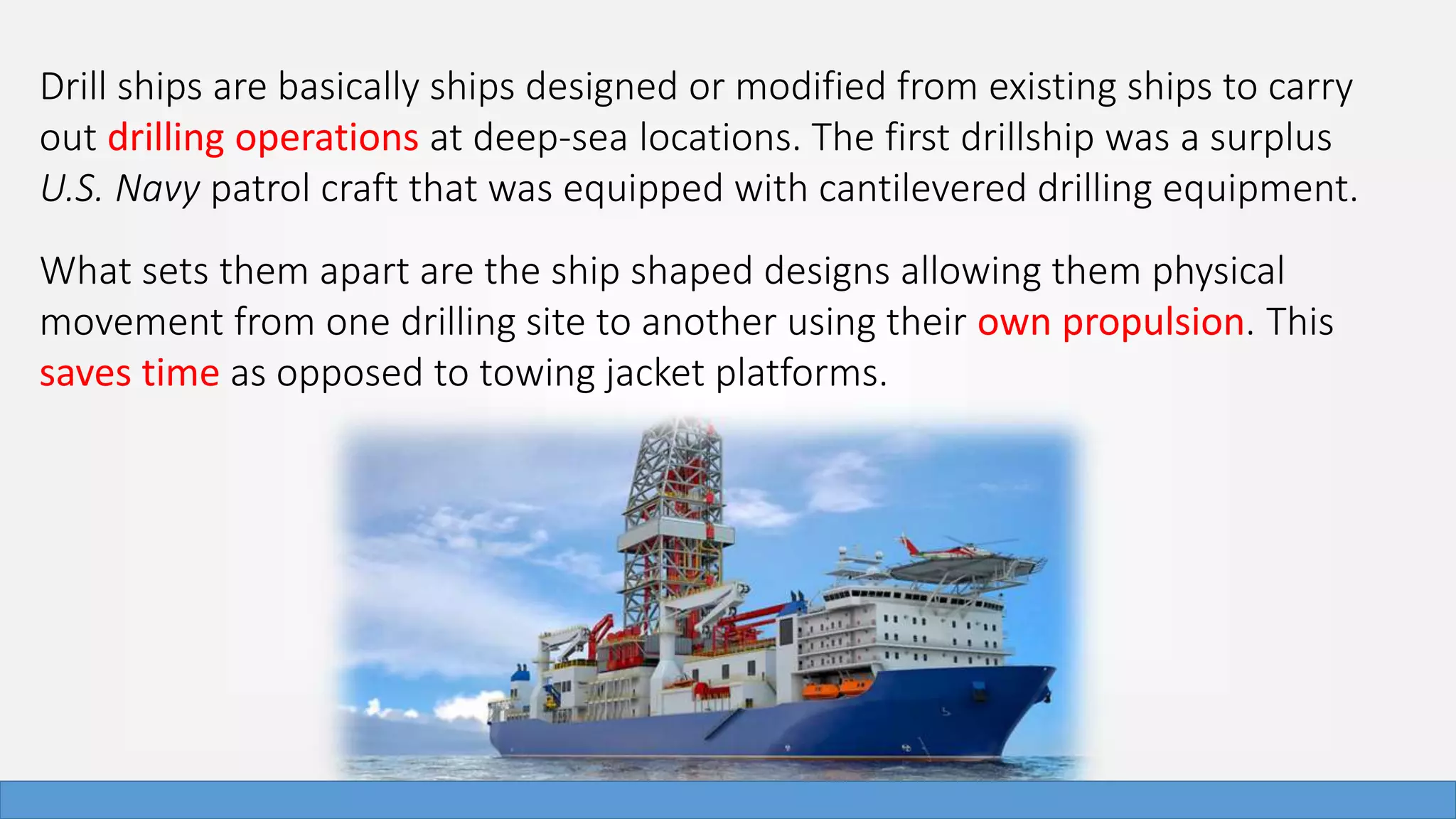

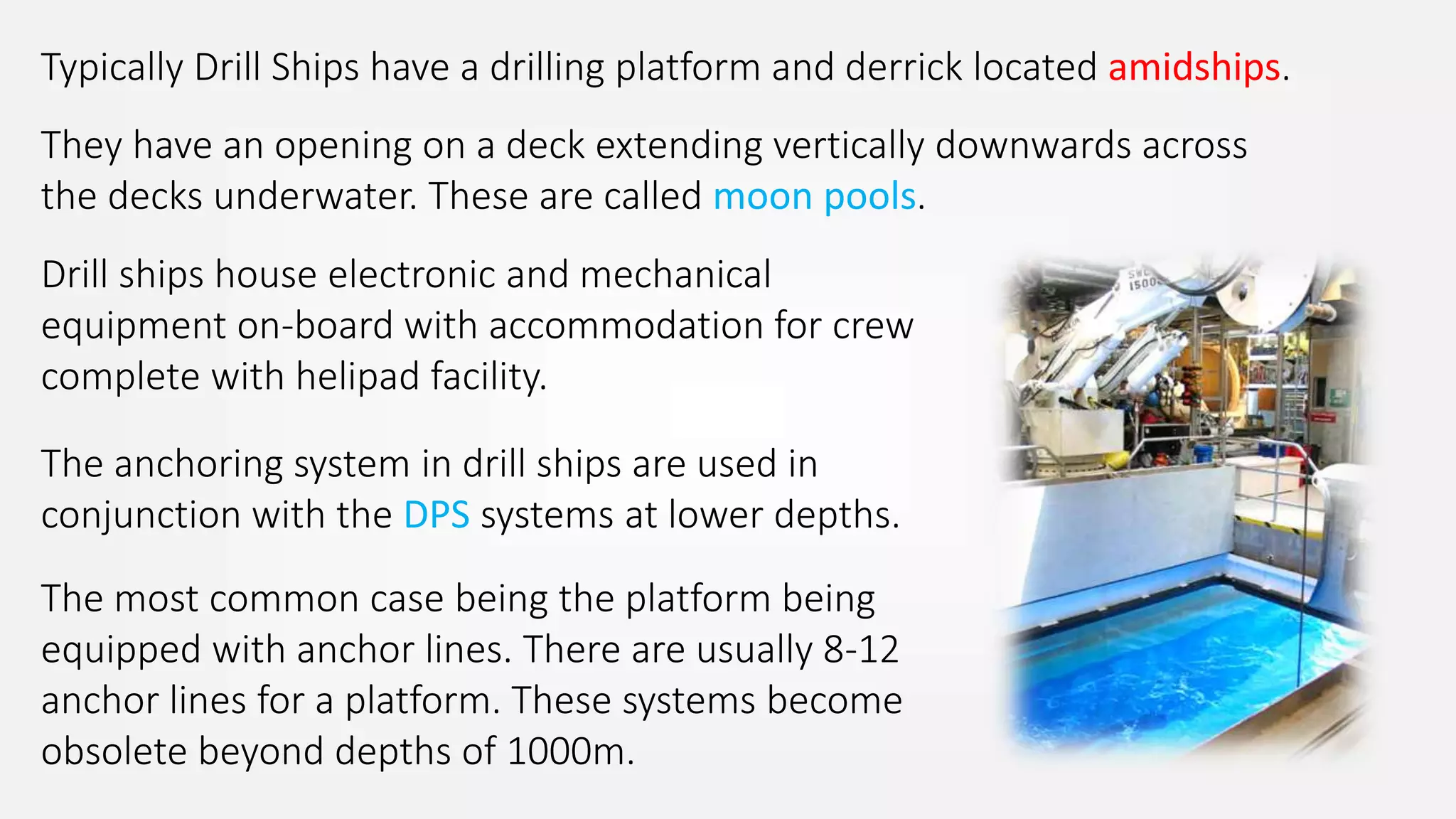

Drill ships are modified ships designed to carry out deep sea drilling operations. They have drilling platforms and derricks amidships, with openings called moon pools that extend down through the decks. Dynamic positioning systems and anchors help stabilize drill ships in deep, turbulent waters where they conduct exploratory drilling. Drill ships can move between drilling sites under their own power, saving time compared to towing semi-submersible platforms. However, drill ships face challenges with stability in rougher seas compared to semi-submersibles.