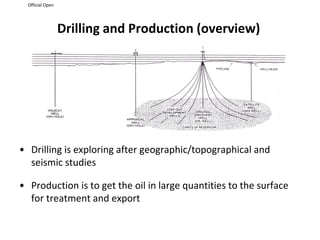

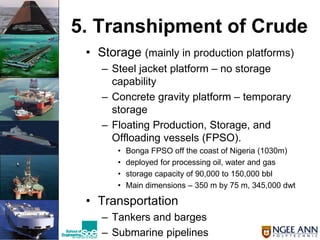

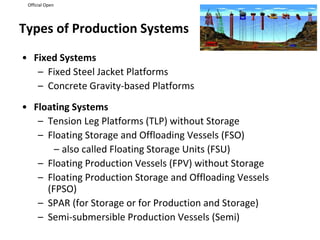

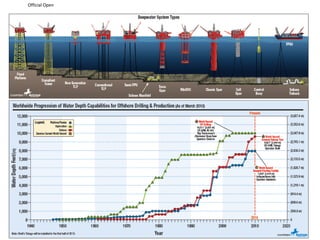

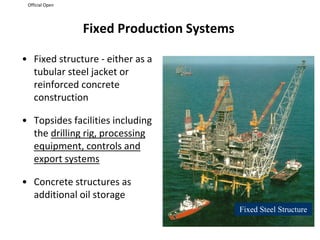

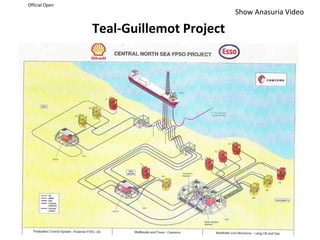

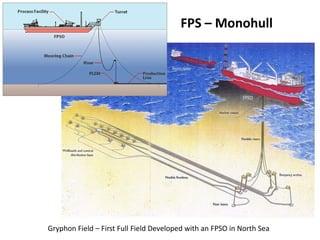

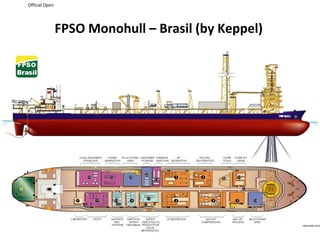

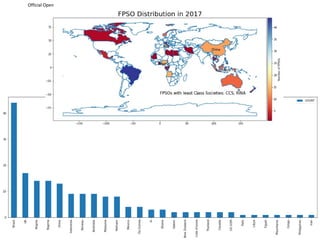

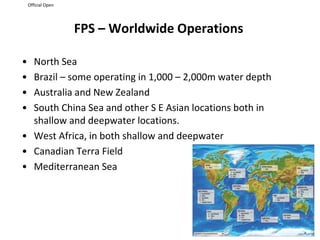

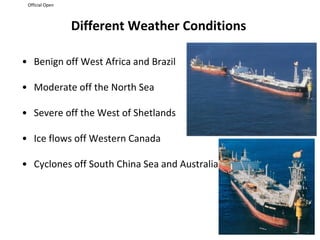

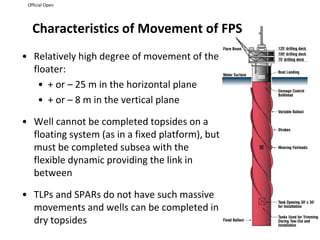

The document discusses offshore oil and gas production and focuses on floating production storage and offloading (FPSO) platforms. It describes FPSOs as having four key functions - floating, production, storage, and offloading. FPSOs are preferred for remote locations, smaller marginal fields, deep waters where fixed platforms are not viable, and areas where mobility is needed to avoid harsh weather. Their modular, self-contained design also makes them easier to decommission and reuse compared to fixed platforms.