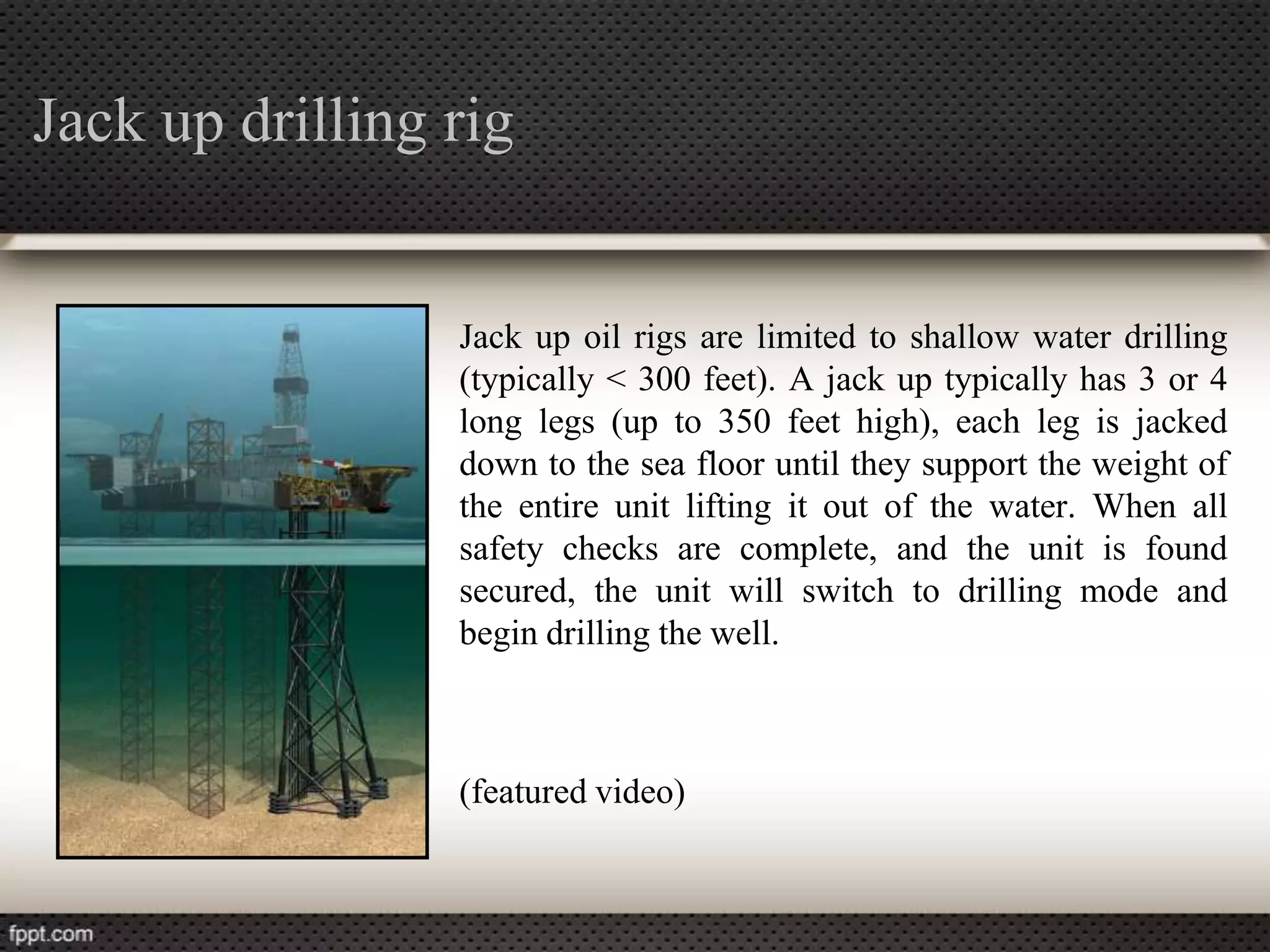

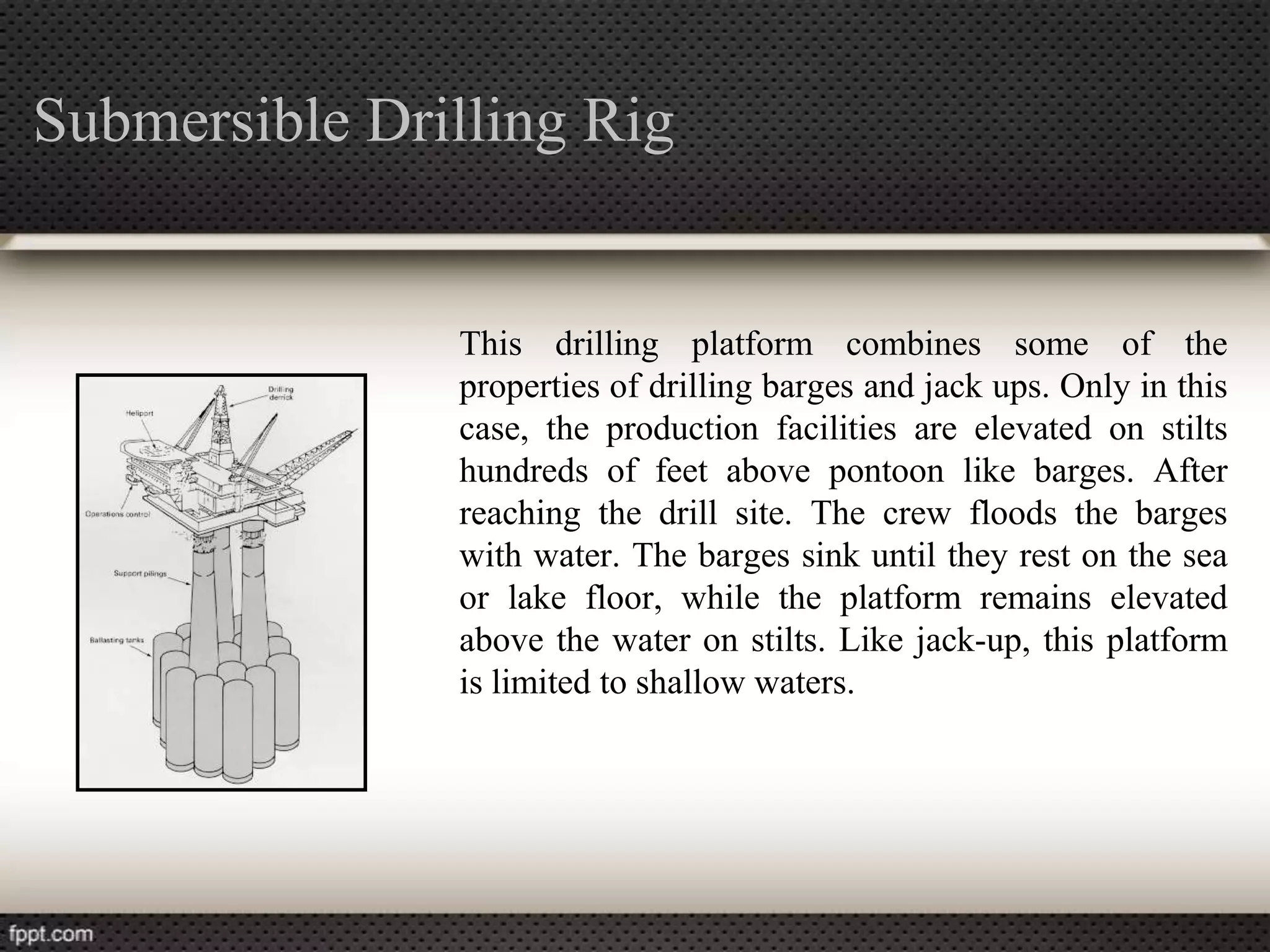

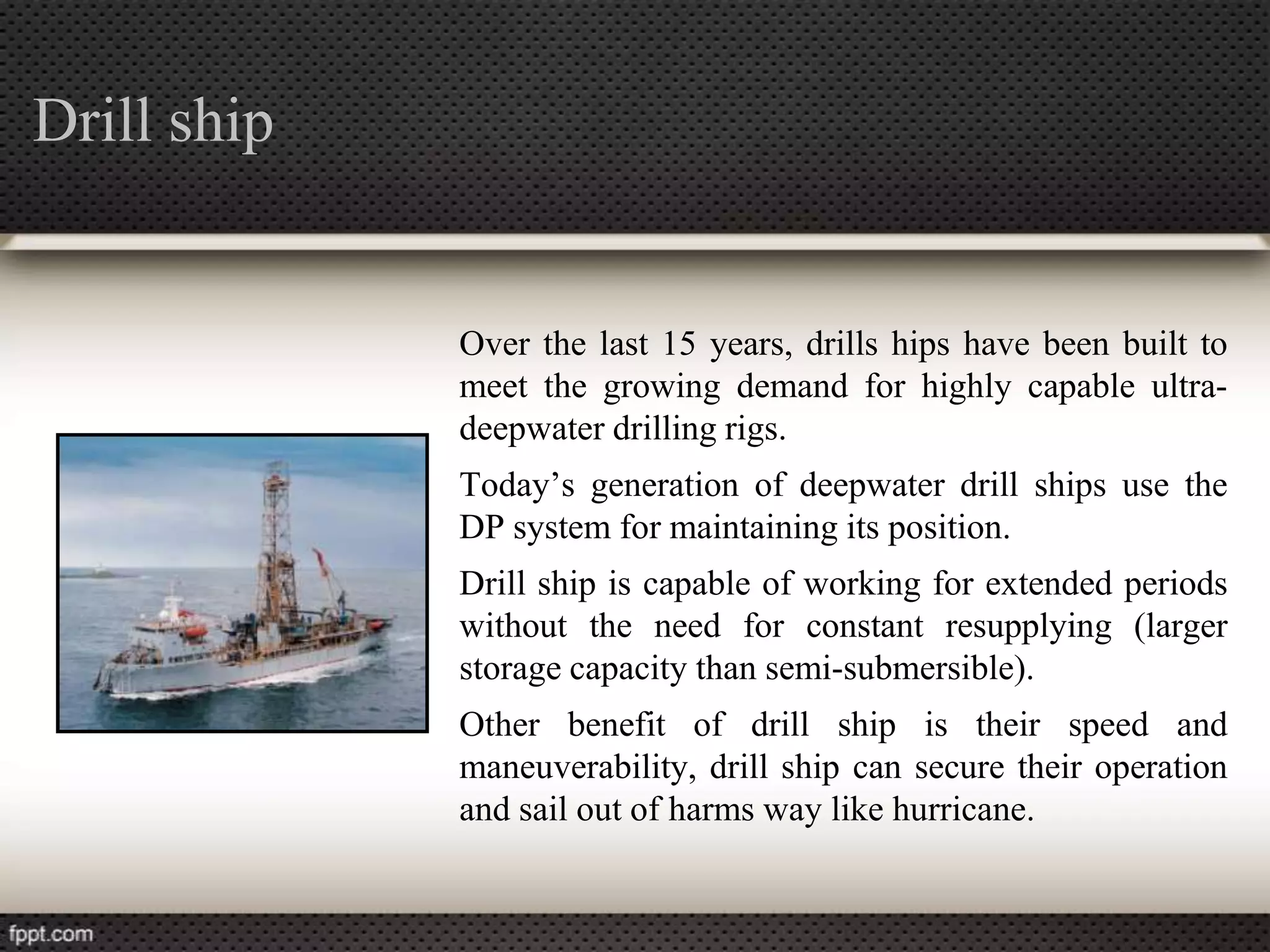

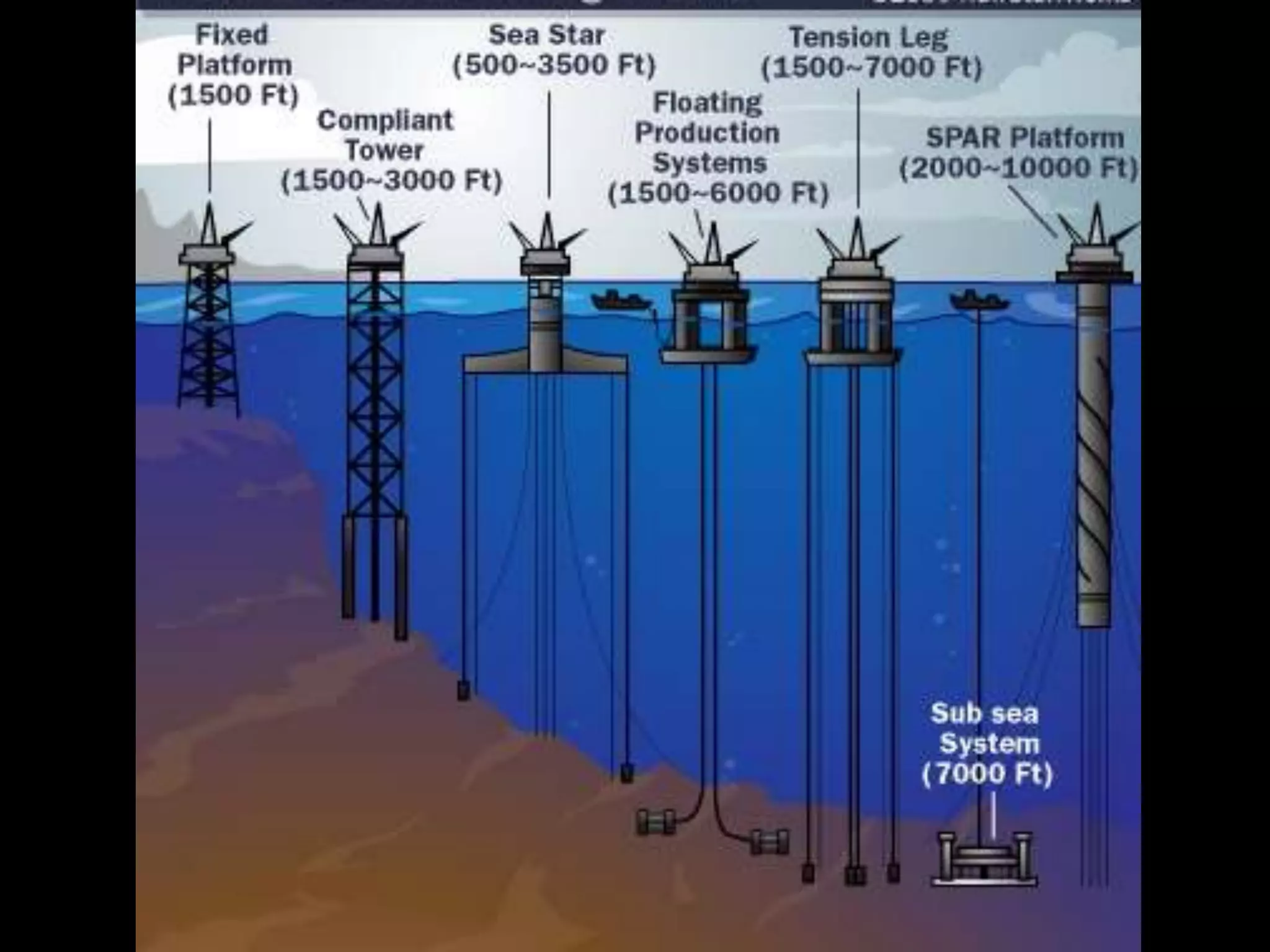

Mobile drilling platforms like jack-ups and semi-submersibles are used to explore for oil in shallow and deep waters. They can drill new wells and then move to new locations. Semi-submersibles maintain position over well sites using anchors or dynamic positioning systems. Production platforms are used to extract and process oil from reservoir wells. Offshore engineers work onshore and offshore, designing these structures and overseeing drilling, completions, production and more. Their work requires skills in math, science, teamwork and handling remote, hazardous conditions.