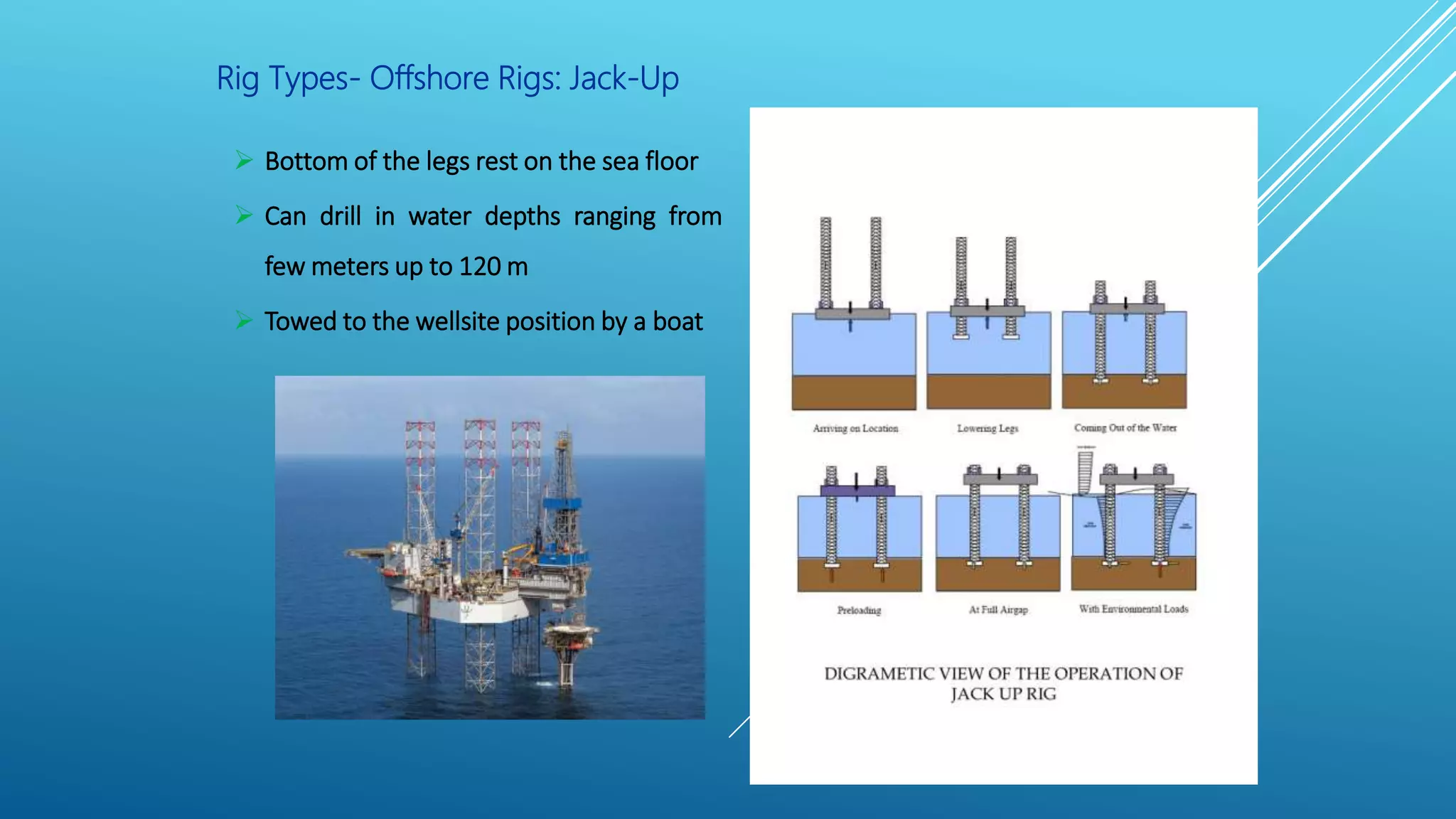

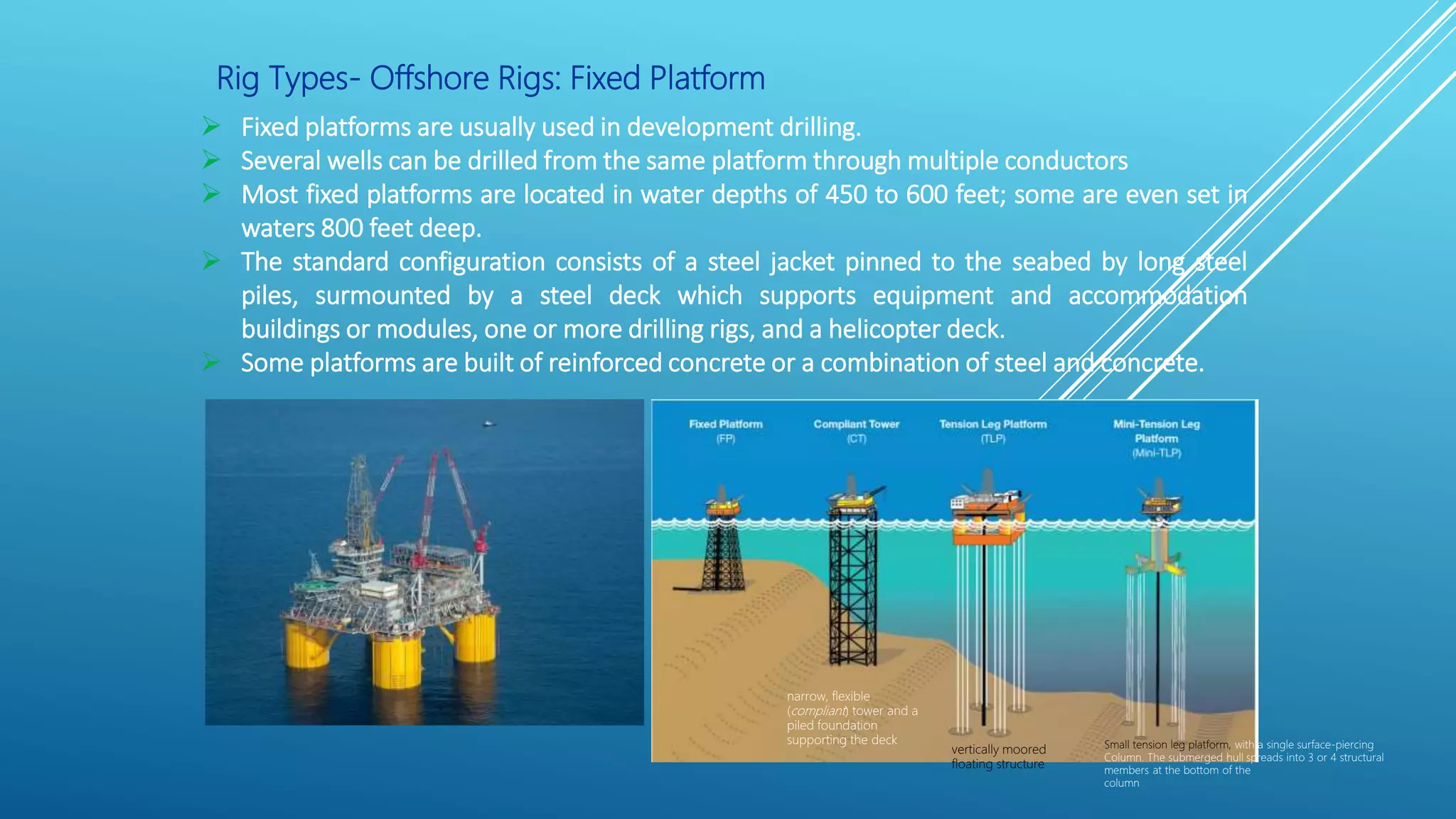

This presentation outlines the various types of drilling rigs, including onshore and offshore rigs, detailing their design, capabilities, and specific uses. Onshore rigs can drill depths of 1,000 to 7,500 meters, while offshore rigs include five types: bottom-supported, jack-up, fixed platform, submersible, and drillship, each suited for different underwater environments. The presentation also mentions the next topics on drilling rig systems, including power, circulating, rotary, hoisting, and well control systems.