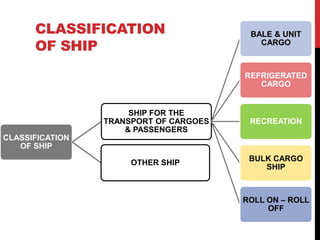

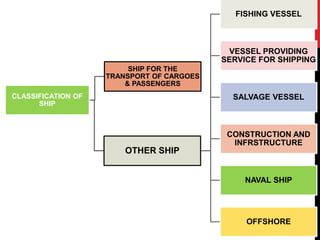

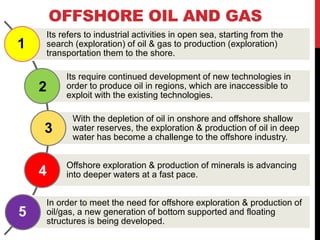

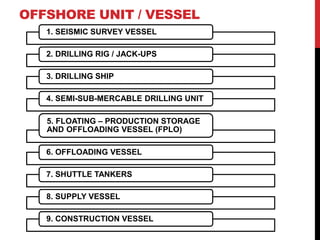

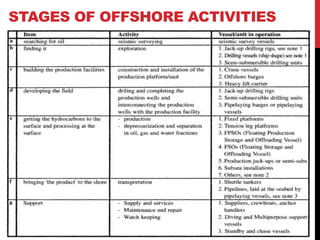

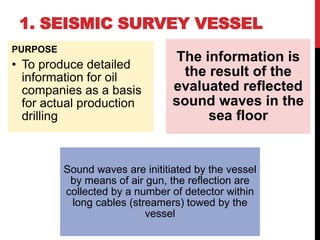

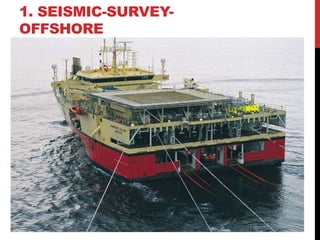

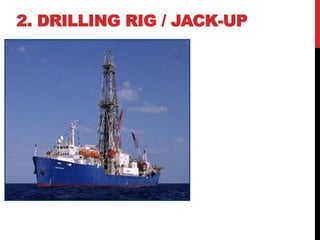

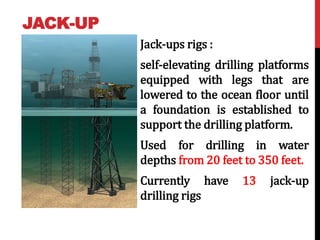

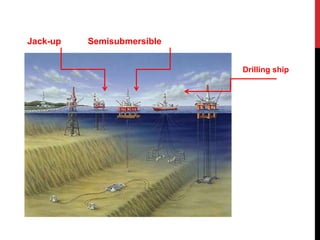

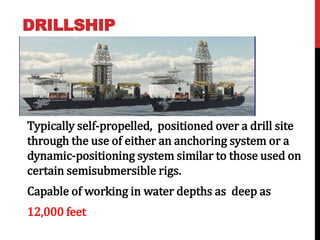

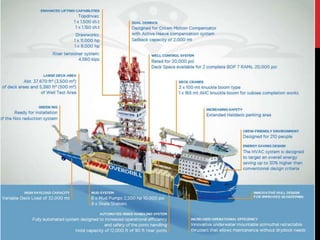

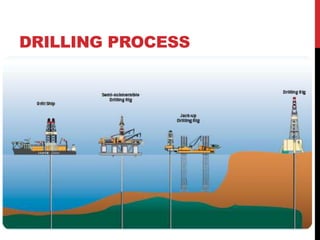

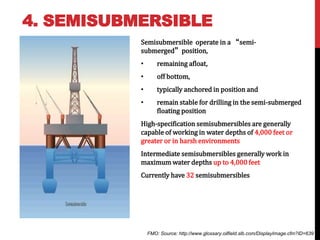

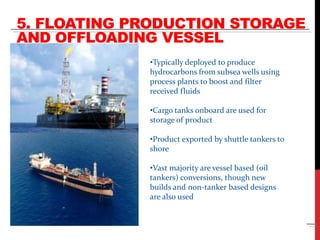

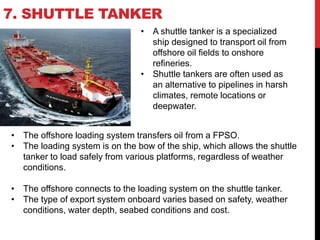

The document classifies various types of ships used for transporting cargo and passengers, including specialized vessels for offshore oil and gas exploration. It details the functions of different offshore vessels such as seismic survey ships, drilling rigs, and floating production storage and offloading vessels, as well as naval ships and their missions. The need for advanced technologies in deep-water exploration and production due to depleting resources is also highlighted.