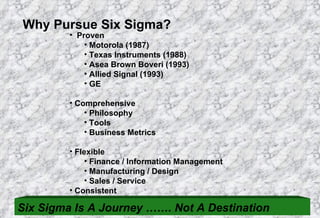

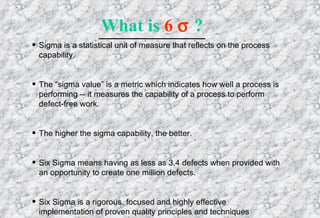

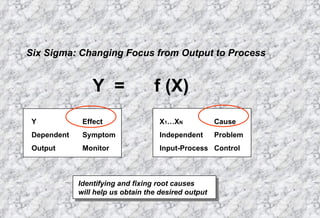

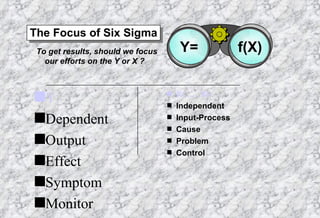

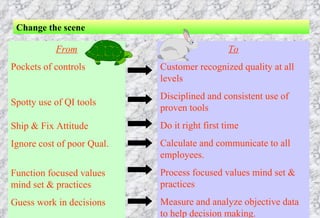

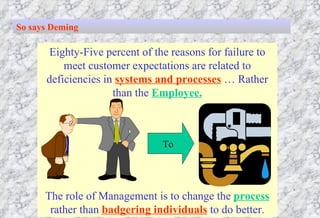

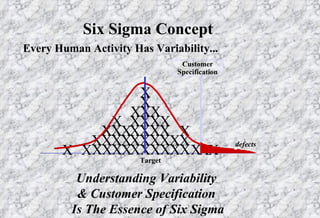

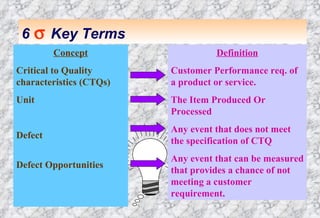

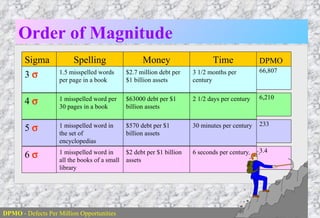

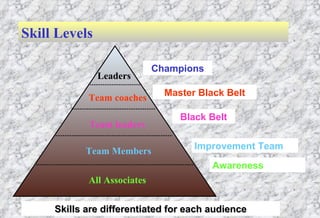

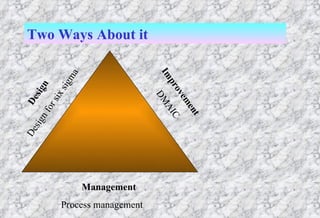

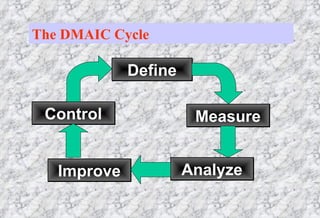

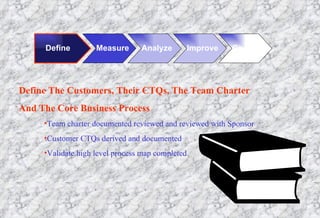

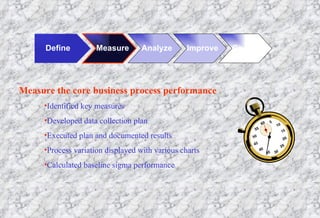

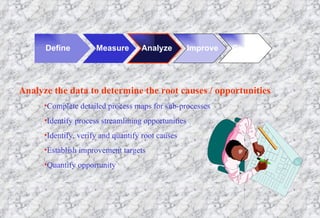

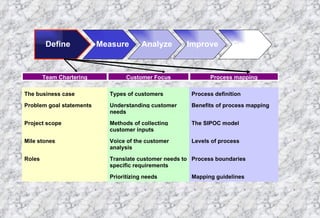

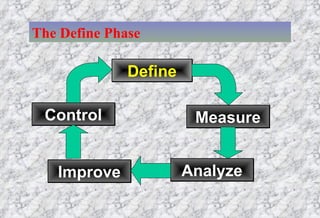

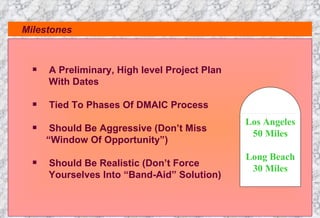

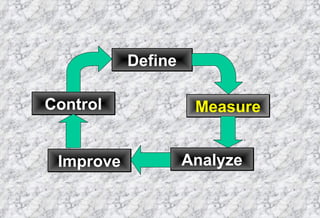

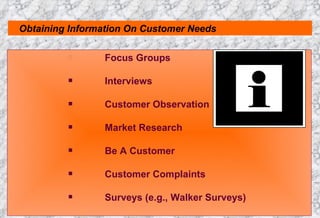

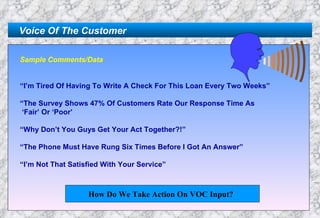

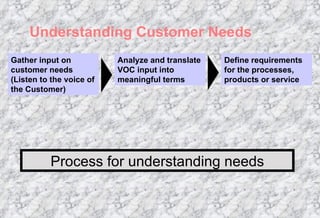

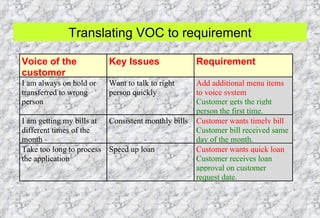

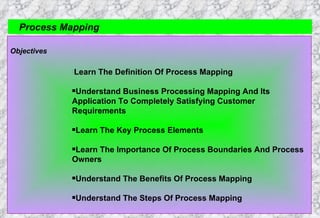

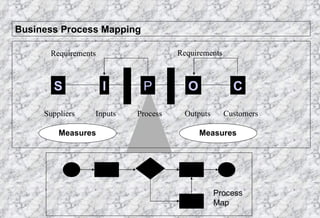

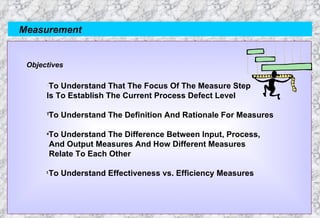

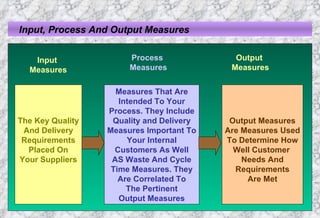

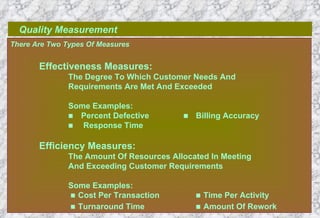

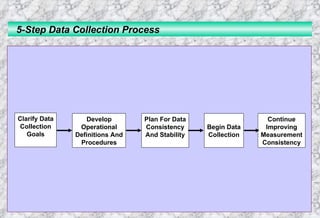

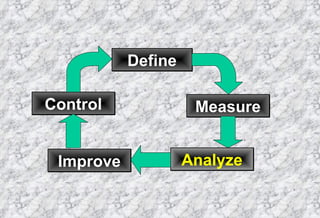

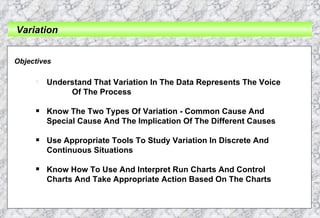

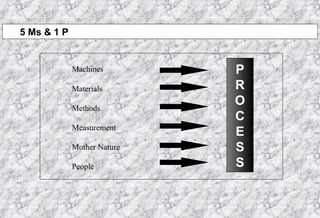

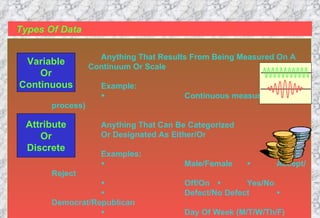

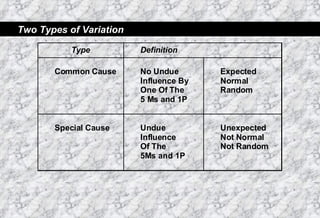

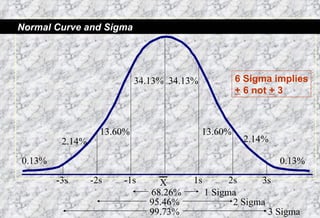

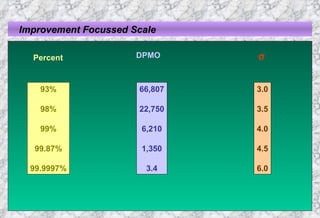

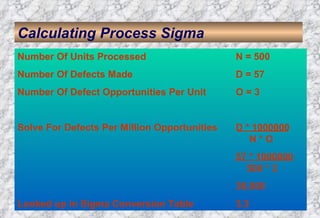

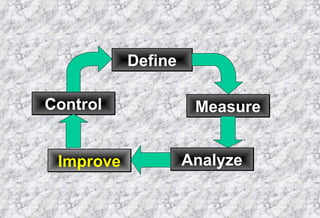

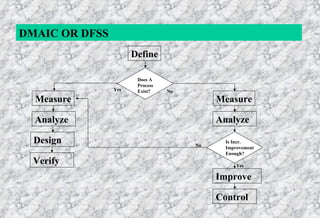

The document provides an overview of Six Sigma and quality management. It defines Six Sigma as a methodology that aims for 3.4 defects per million opportunities by reducing variation and defects in processes. It explains the DMAIC cycle of Define, Measure, Analyze, Improve, and Control used in Six Sigma to systematically improve processes. It also discusses understanding customer requirements, process mapping, and measuring process performance as key aspects of Six Sigma.