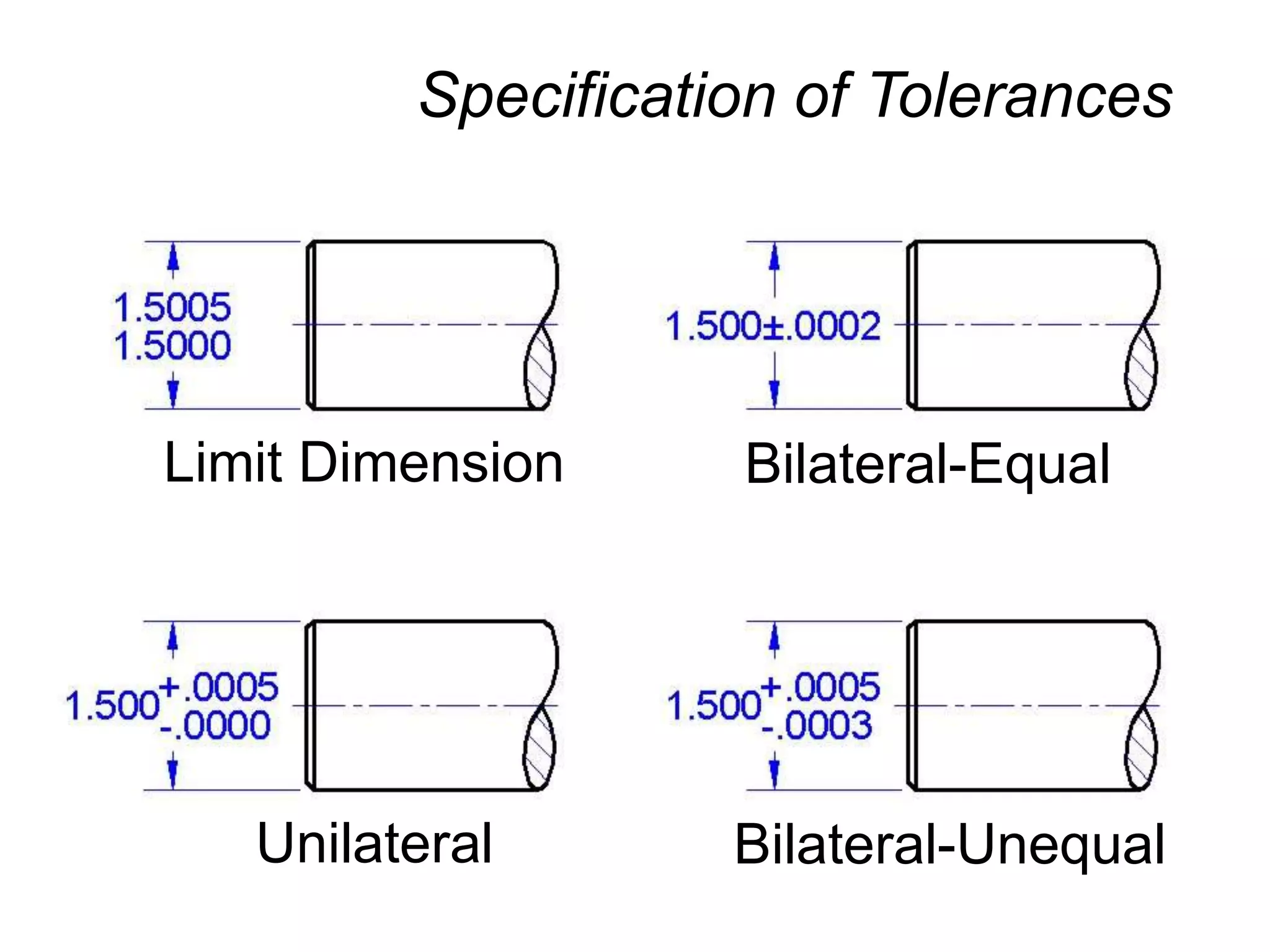

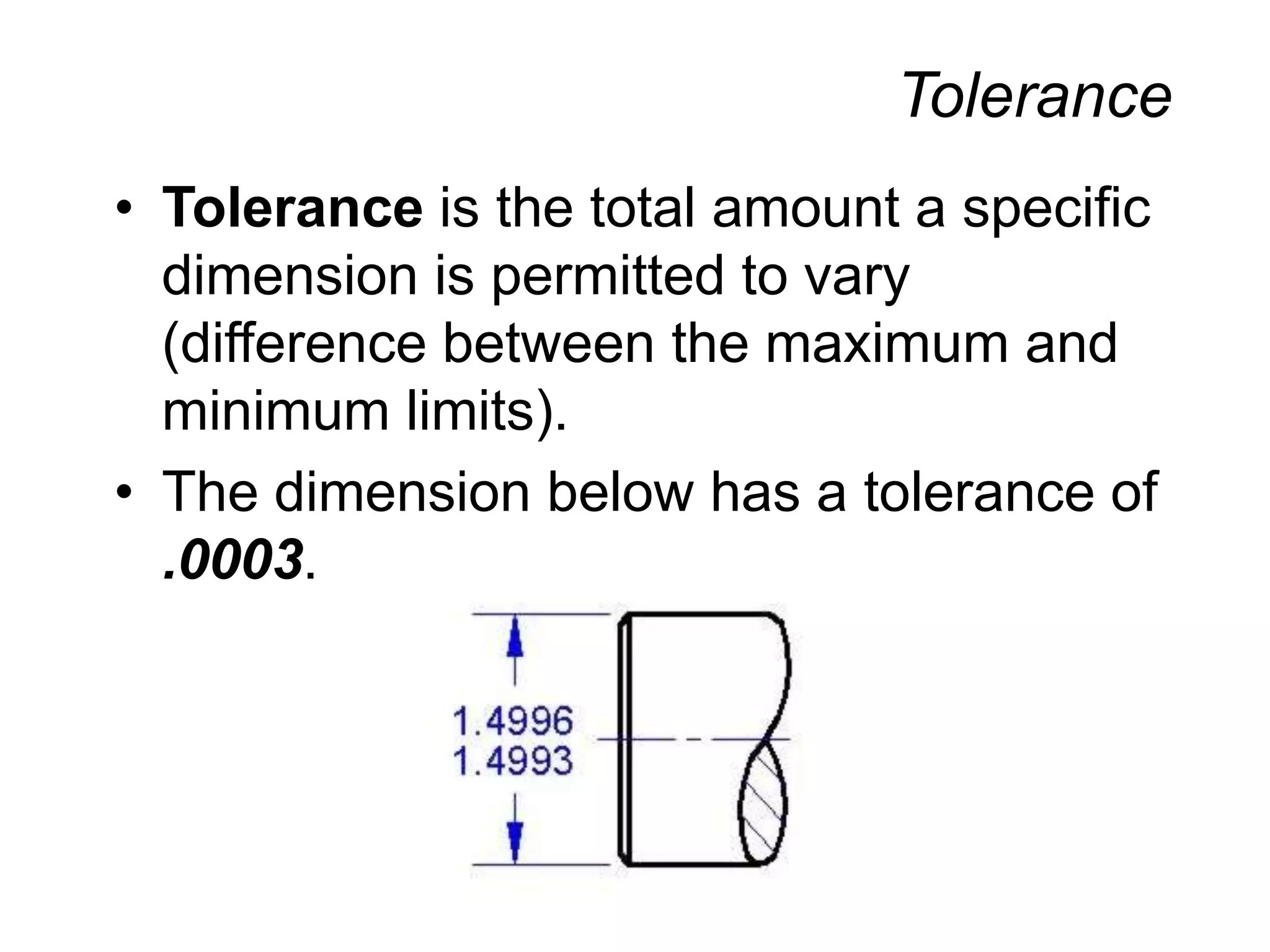

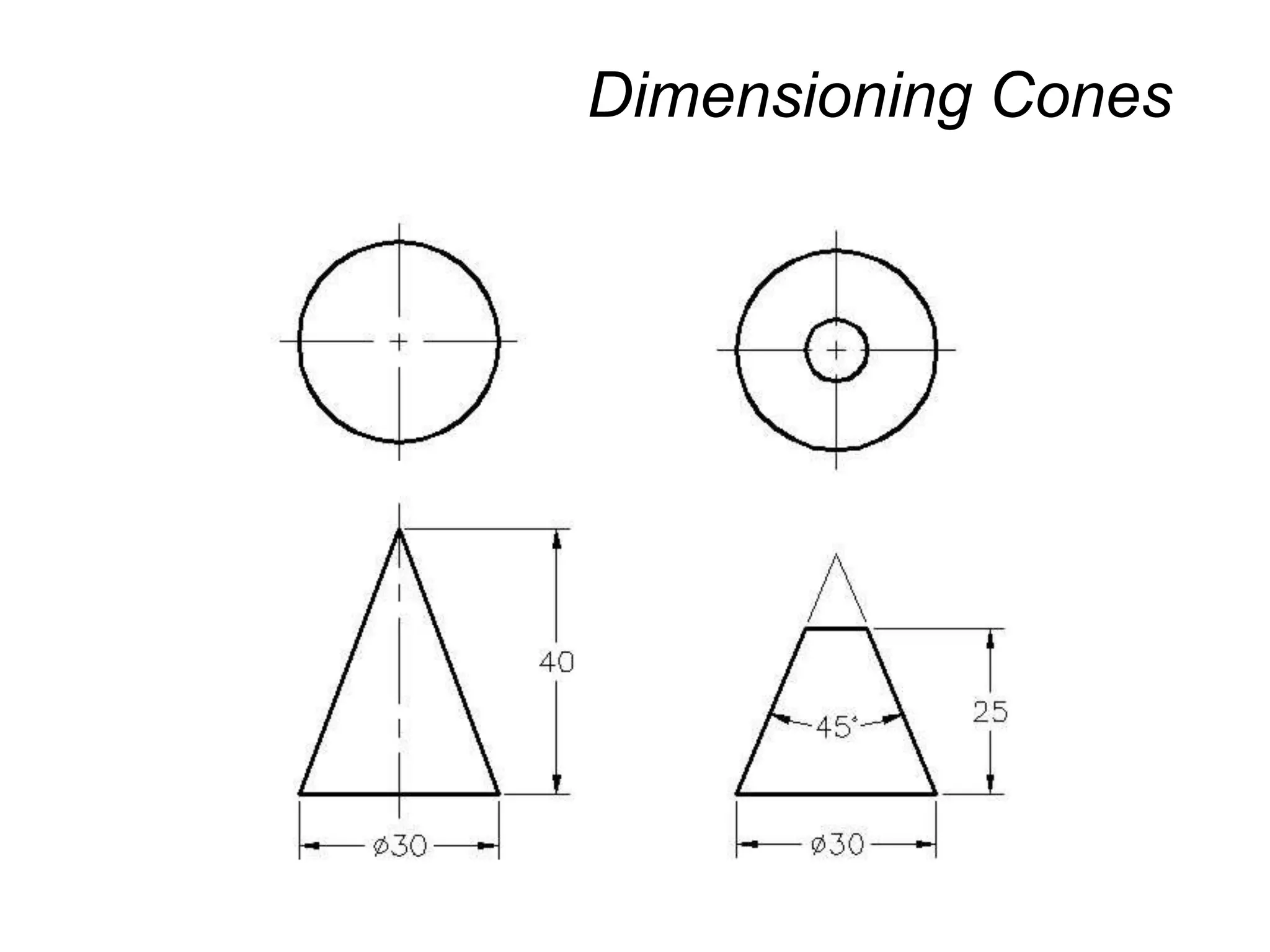

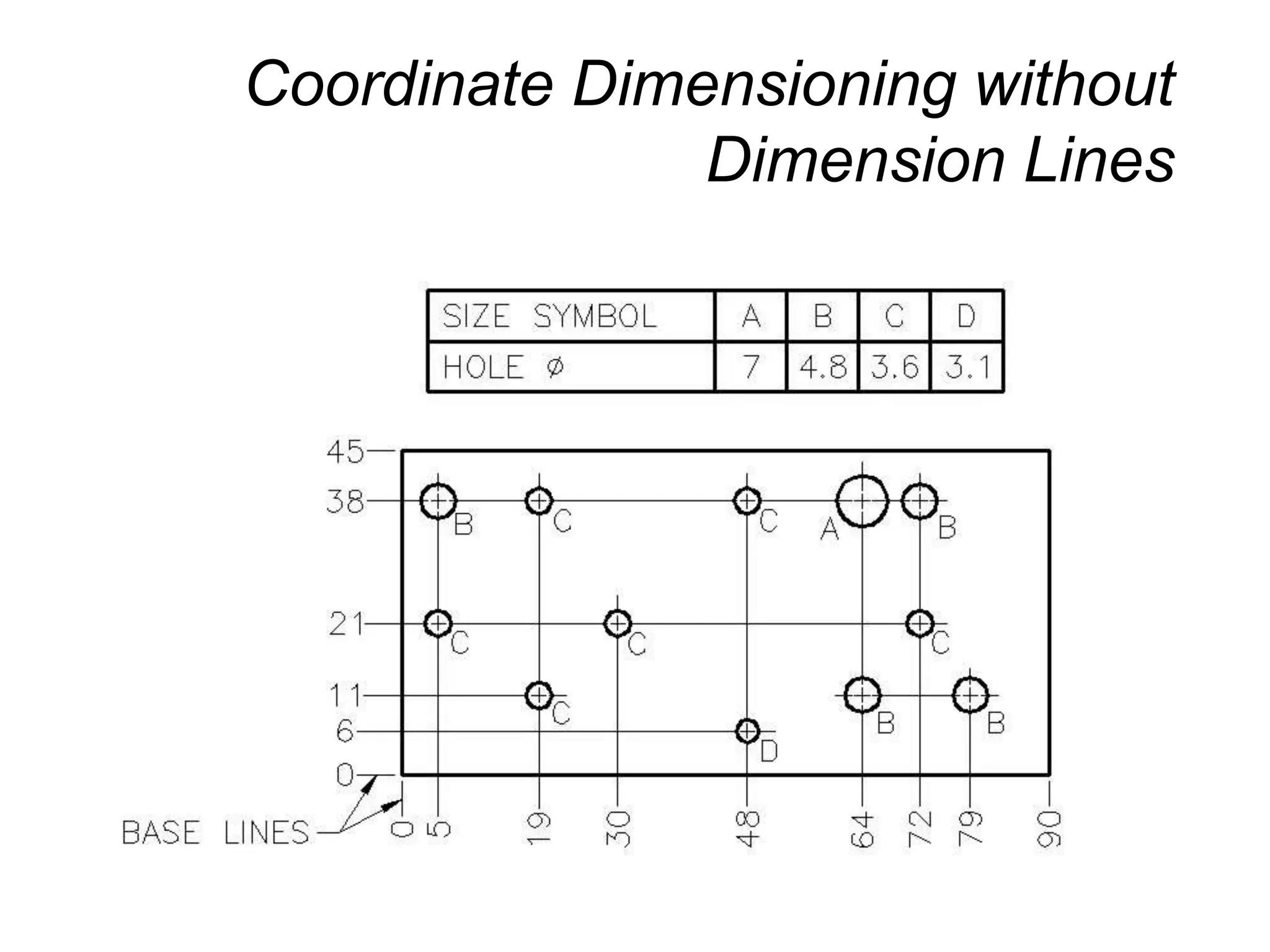

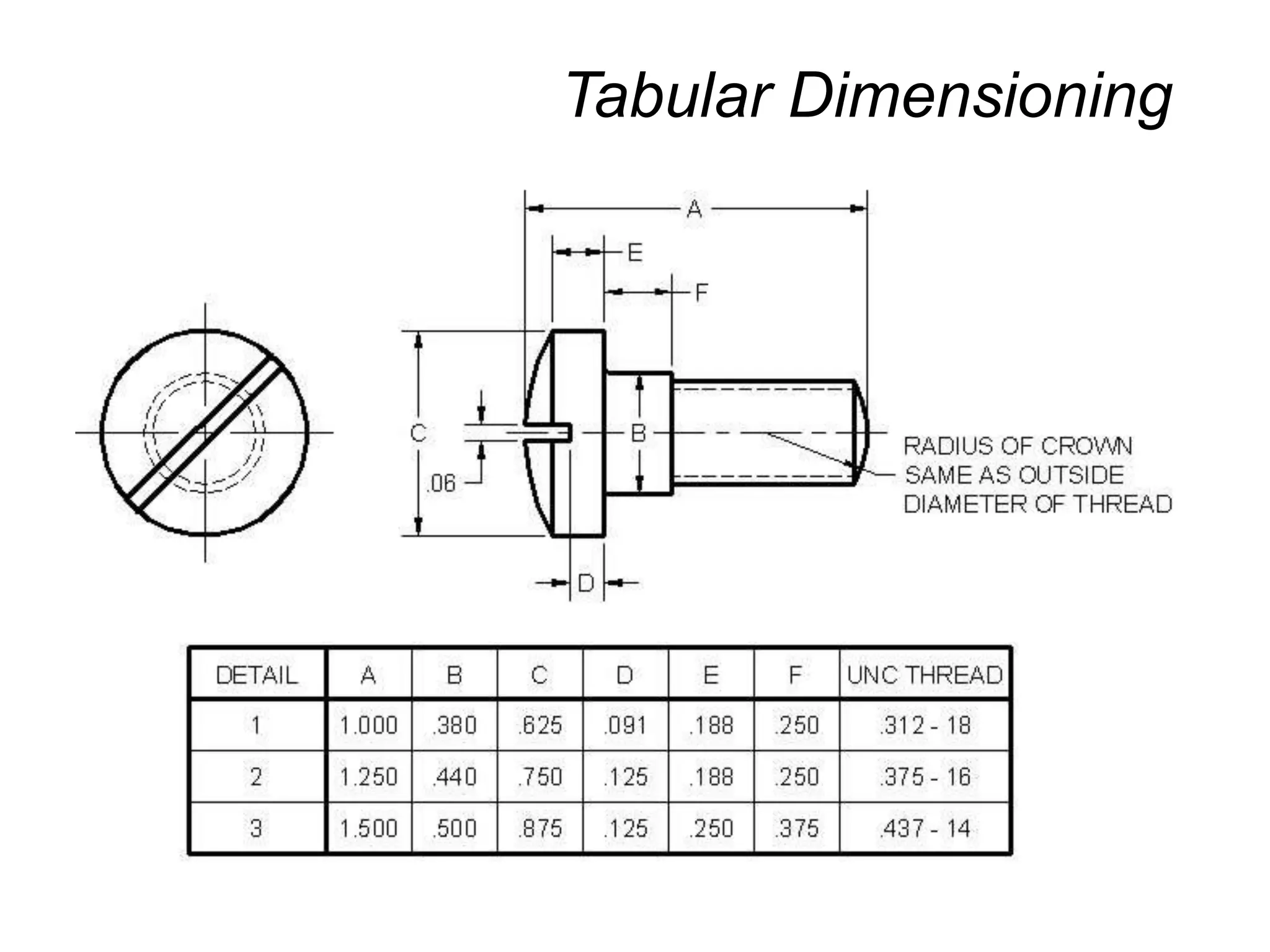

- The document discusses various methods for dimensioning and tolerancing parts in engineering drawings, including dimensioning different geometric shapes, coordinate dimensioning, tabular dimensioning, dual dimensioning, and specifying fits and tolerances.

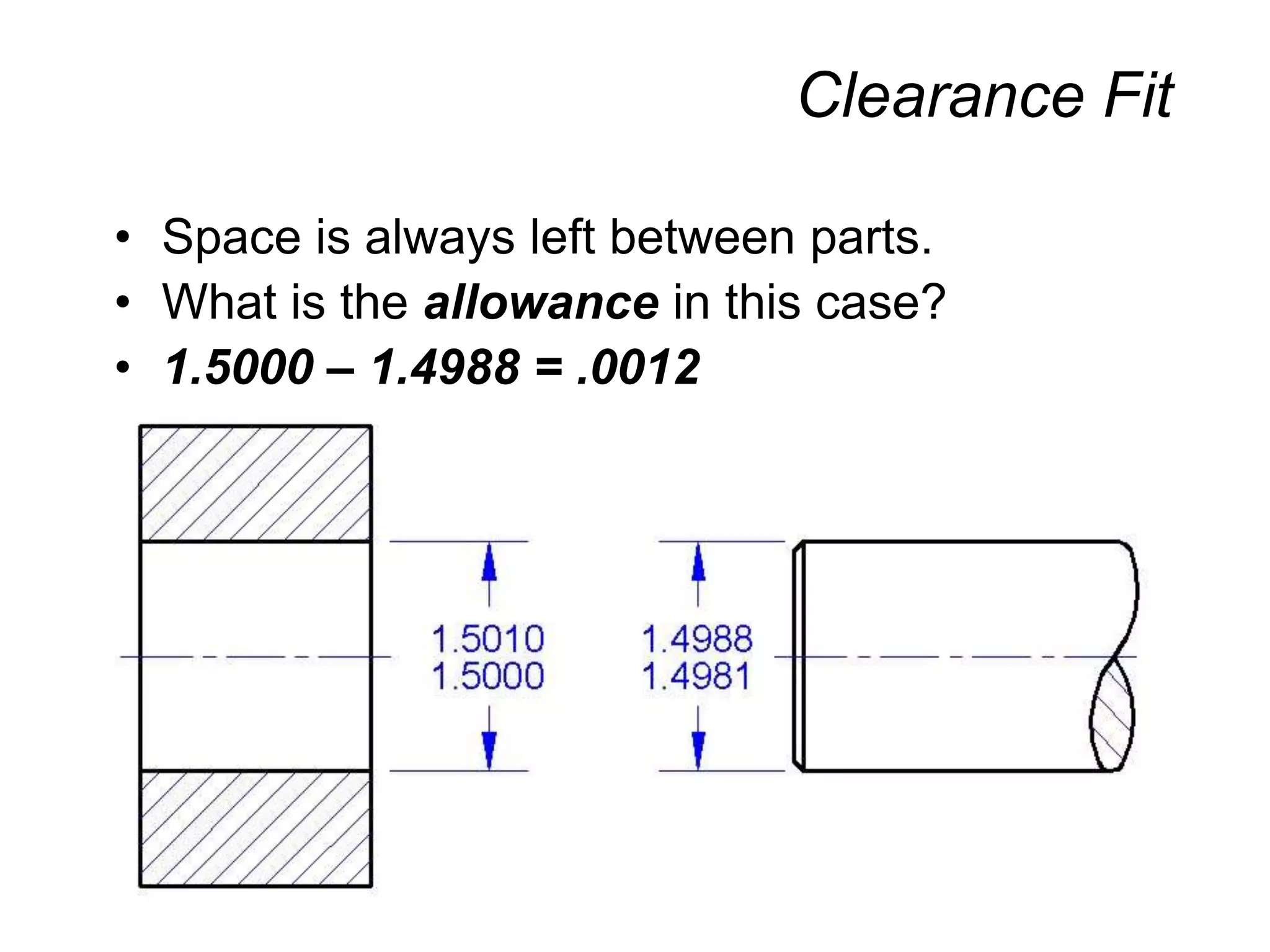

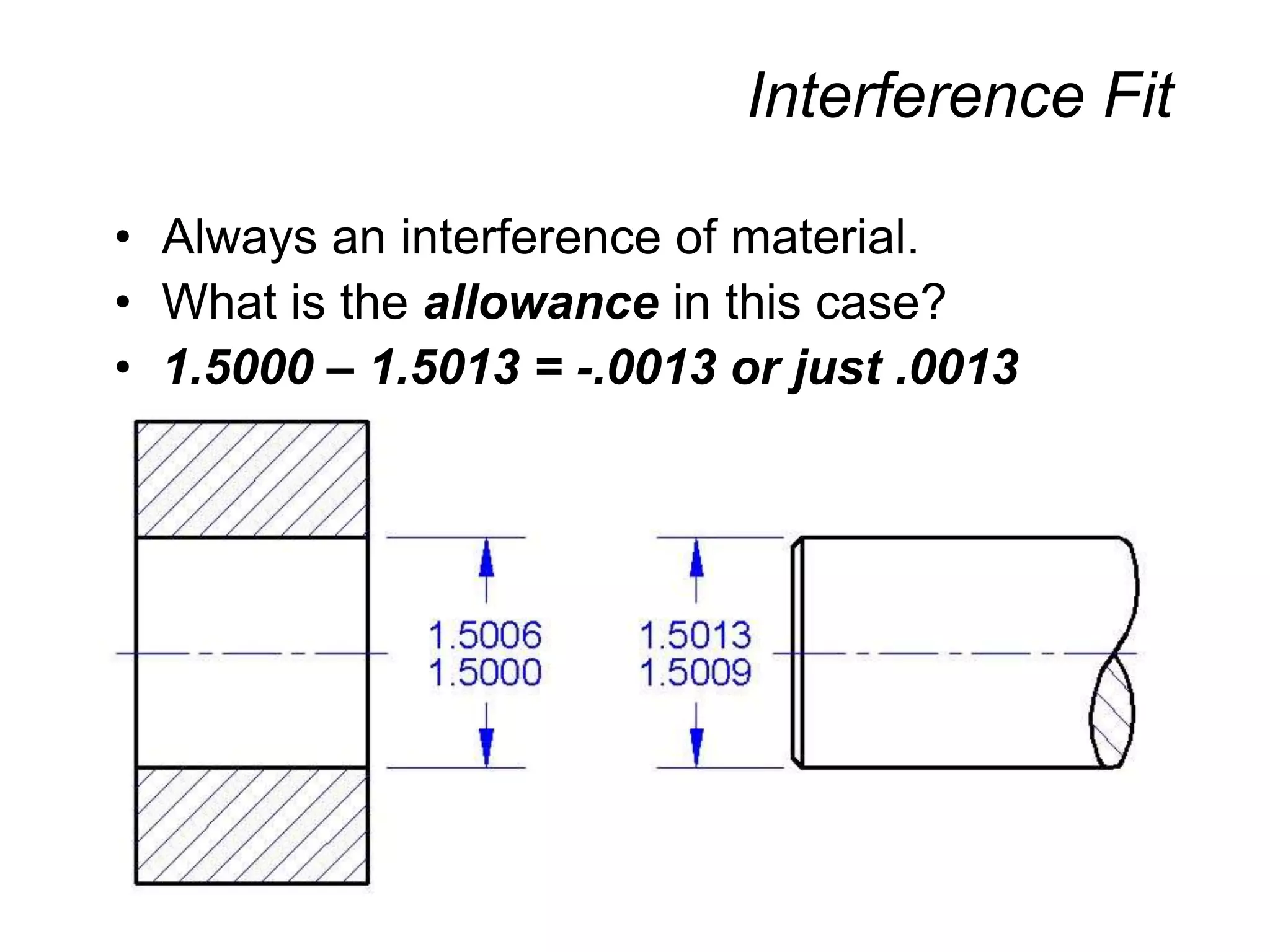

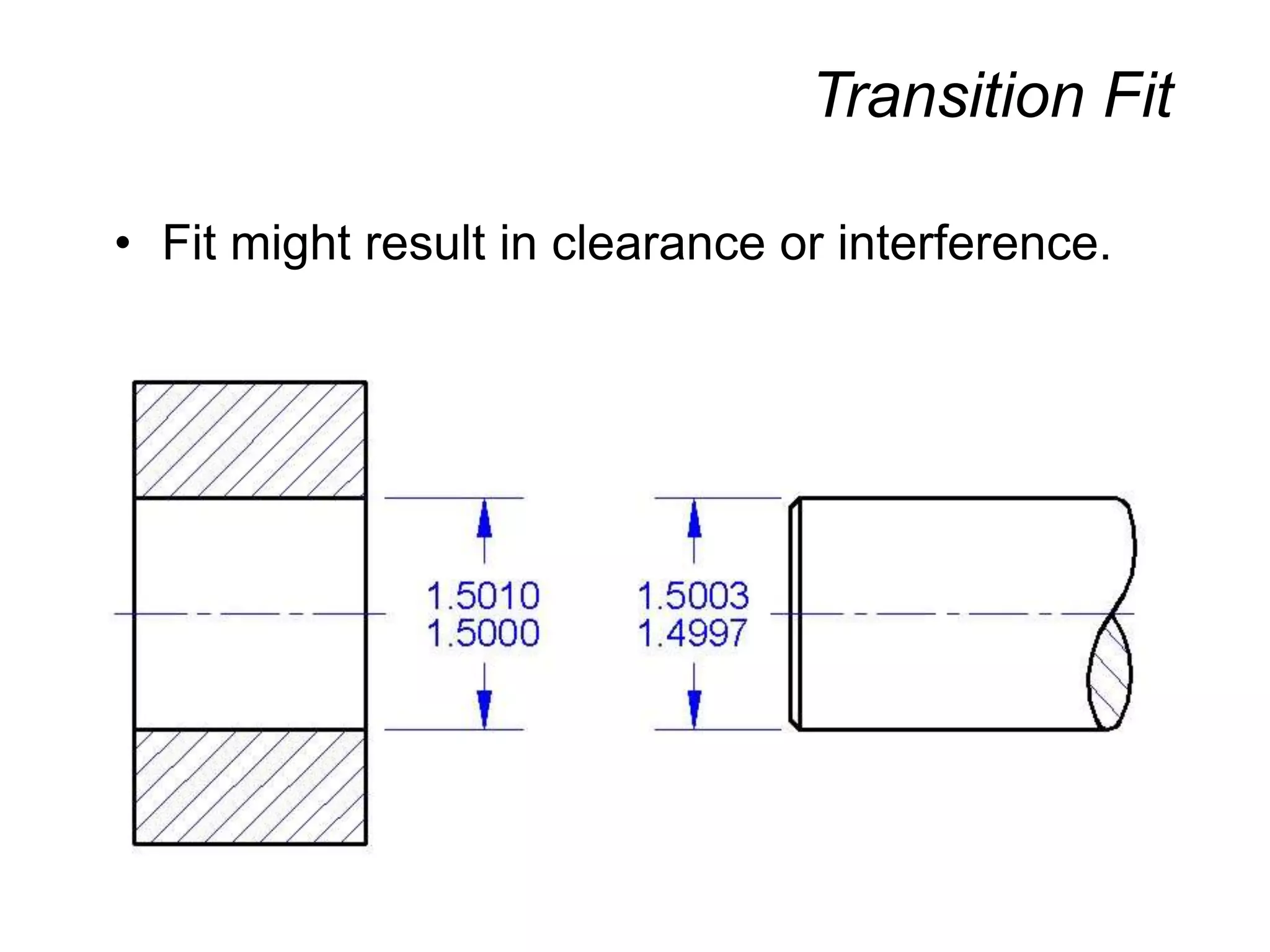

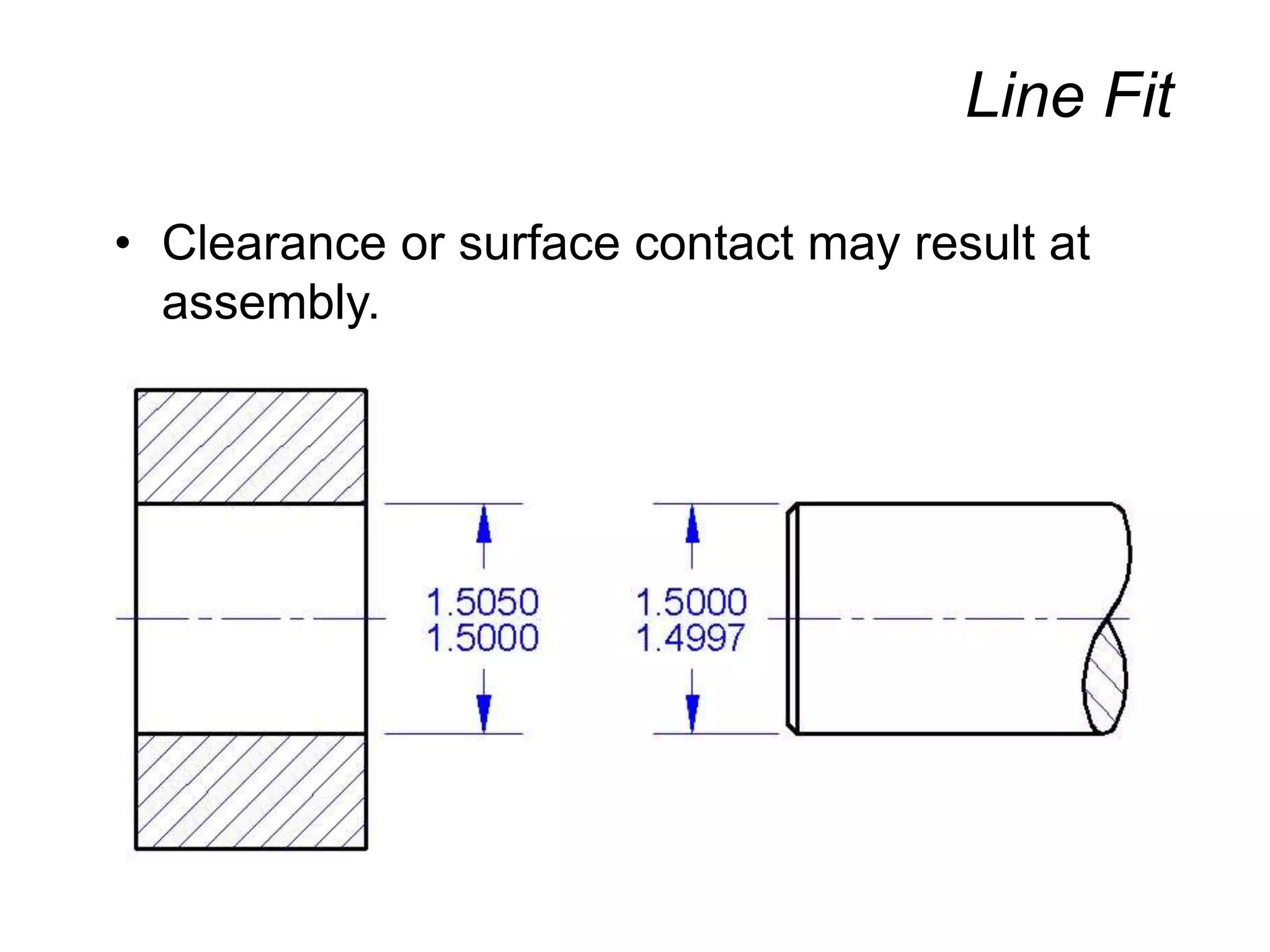

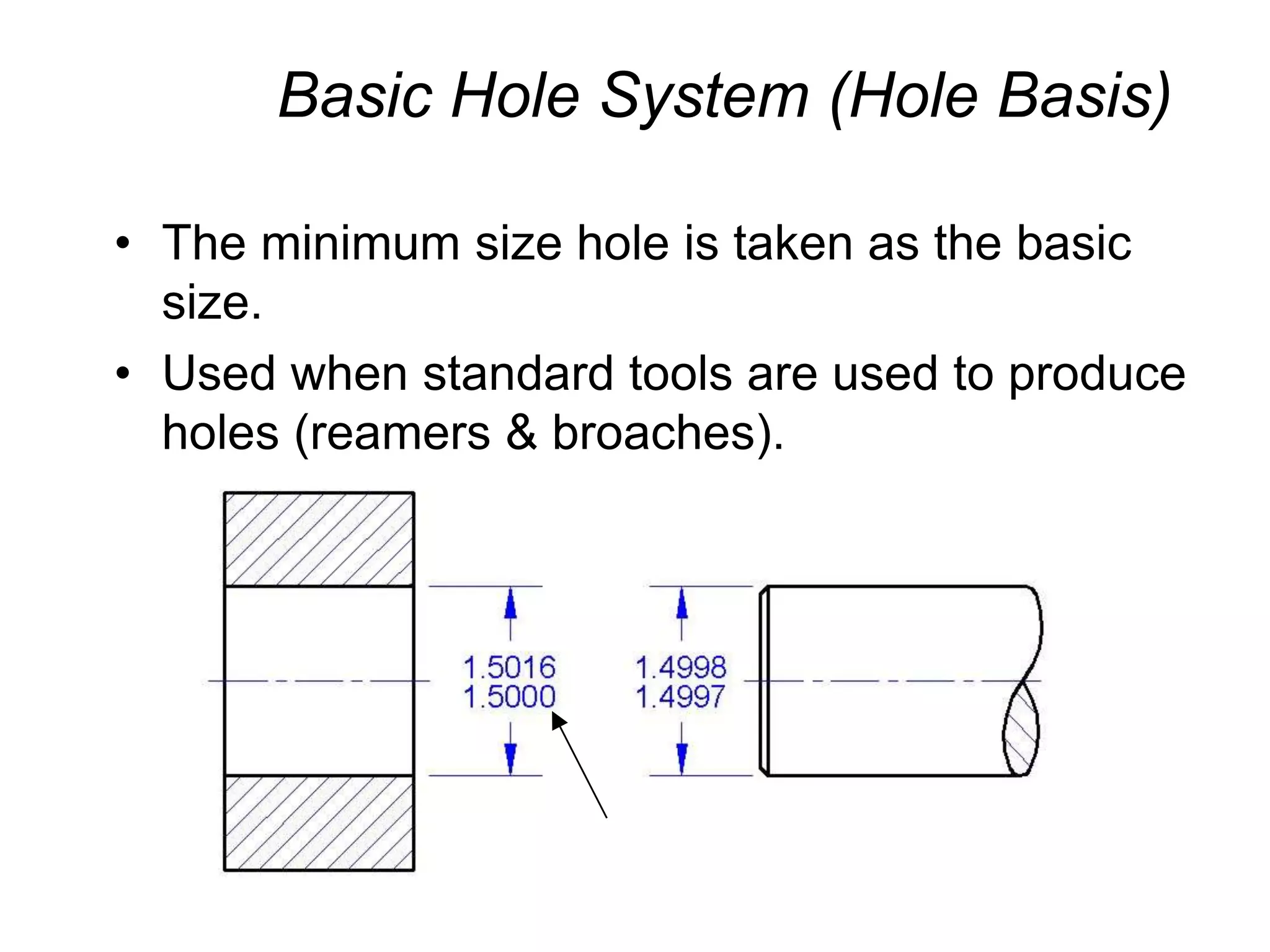

- It explains concepts like maximum material condition, allowance, nominal/basic/actual sizes, and types of fits including clearance, interference, transition, and line fits.

- Tables are presented showing how to specify tolerances for holes and shafts based on fit class and size range in both inch and metric systems.

![Dual Dimensioning – Bracket Method

• Millimeter value is enclosed in square

brackets. A note should be placed on the

drawing such as: DIMENSIONS IN [ ]

ARE MILLIMETERS.](https://image.slidesharecdn.com/dimensionandtolerancingppt-230203220244-a69a25ce/75/Dimension-and-Tolerancing-ppt-ppt-12-2048.jpg)