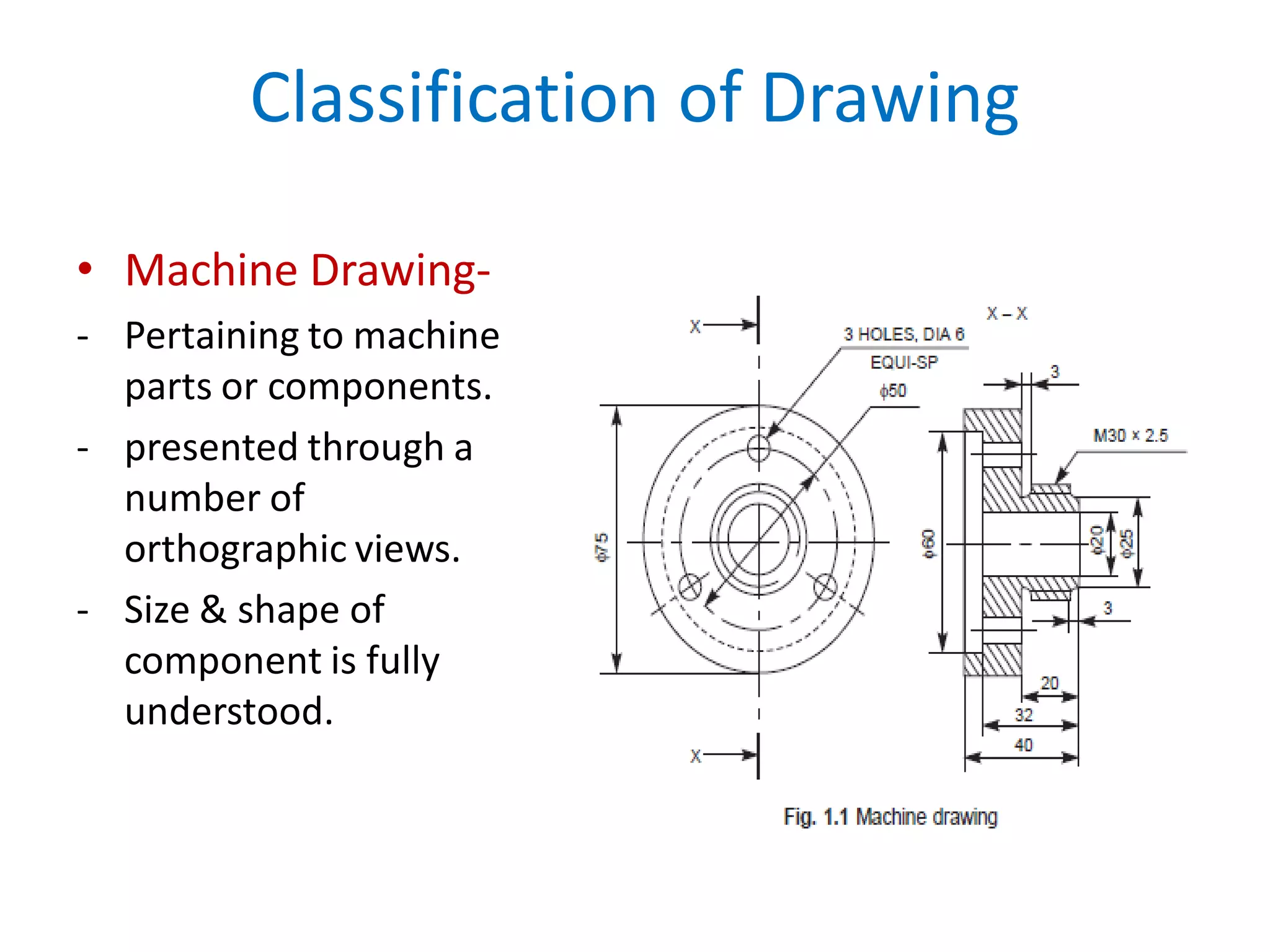

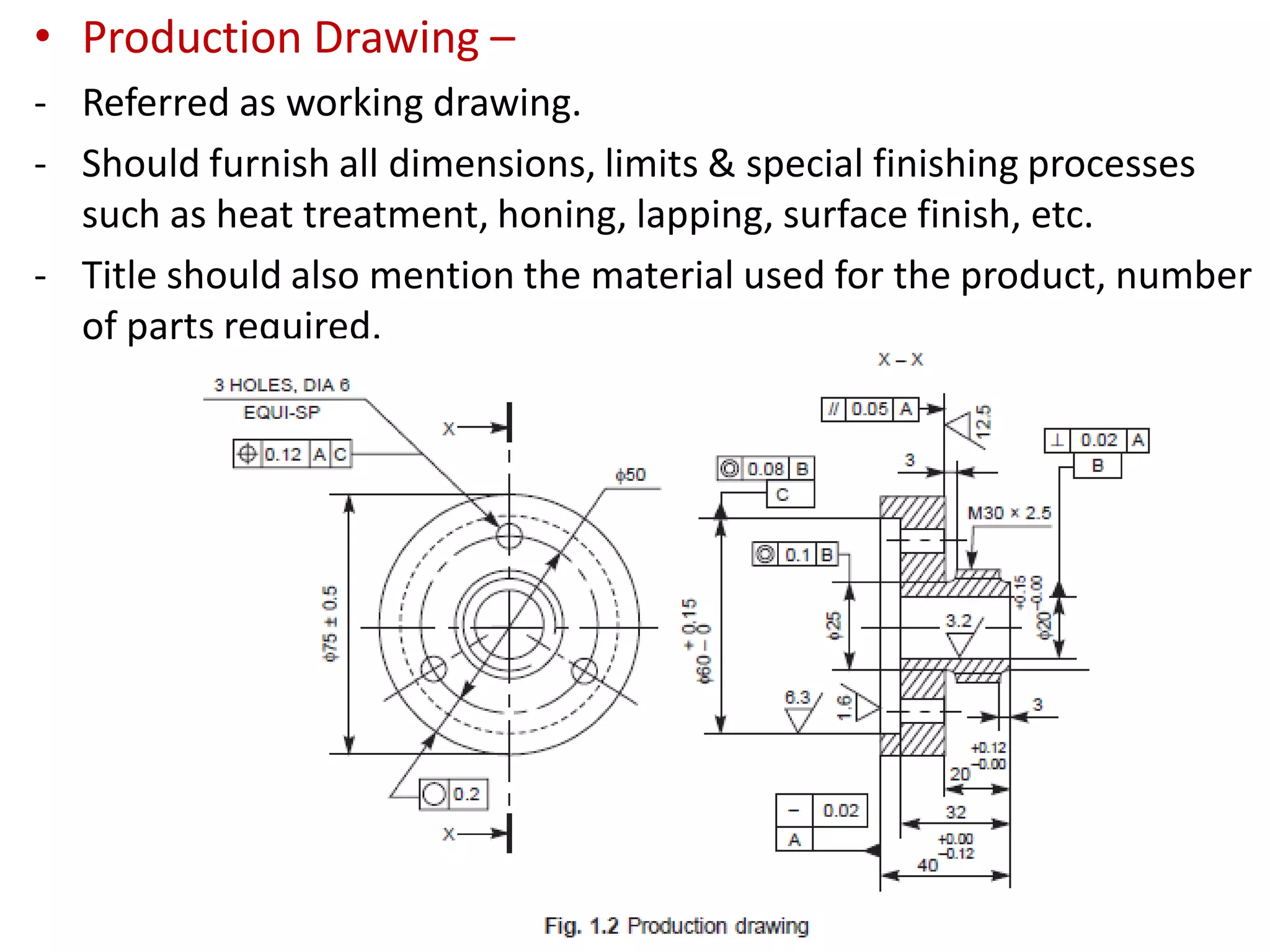

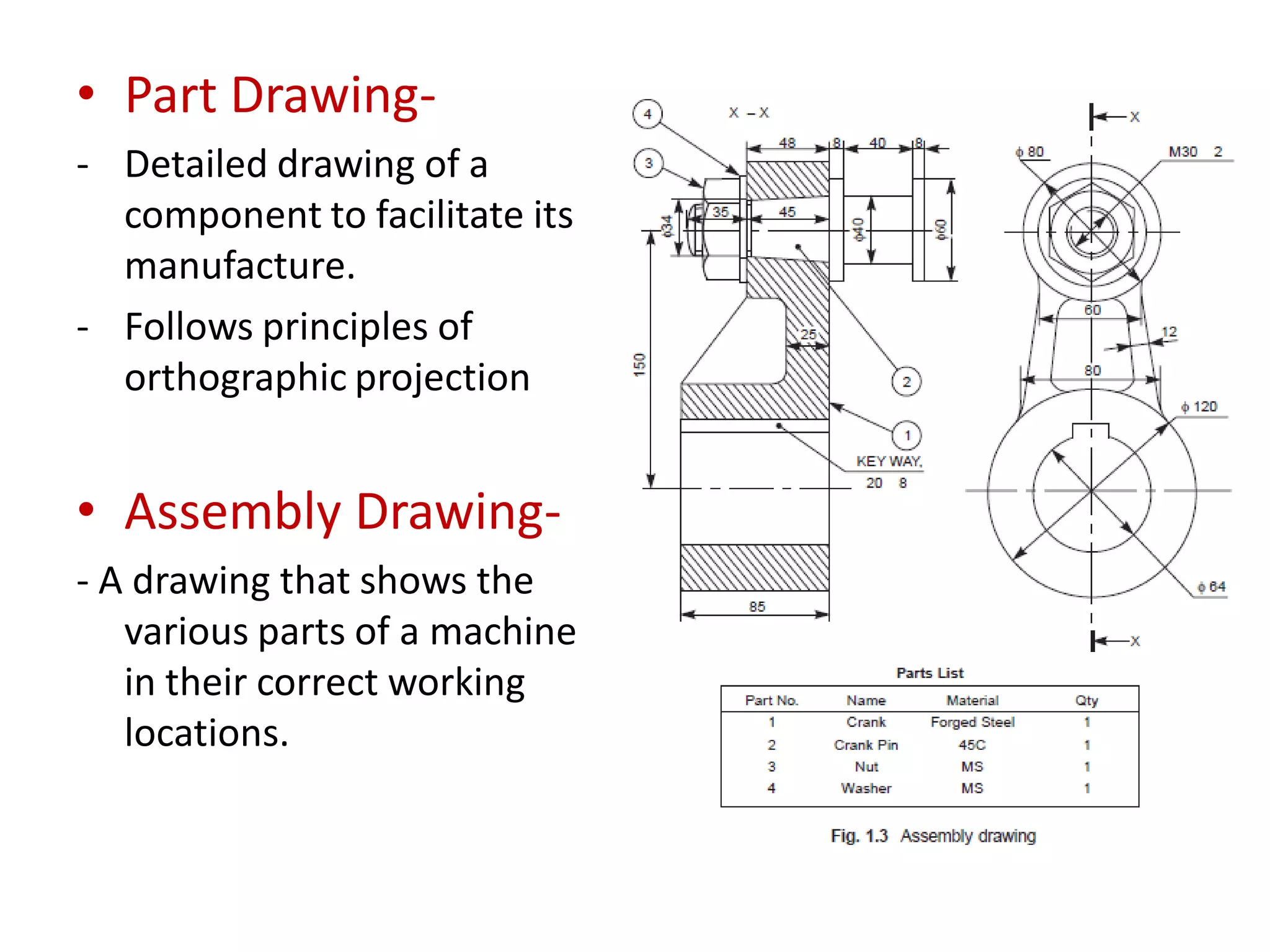

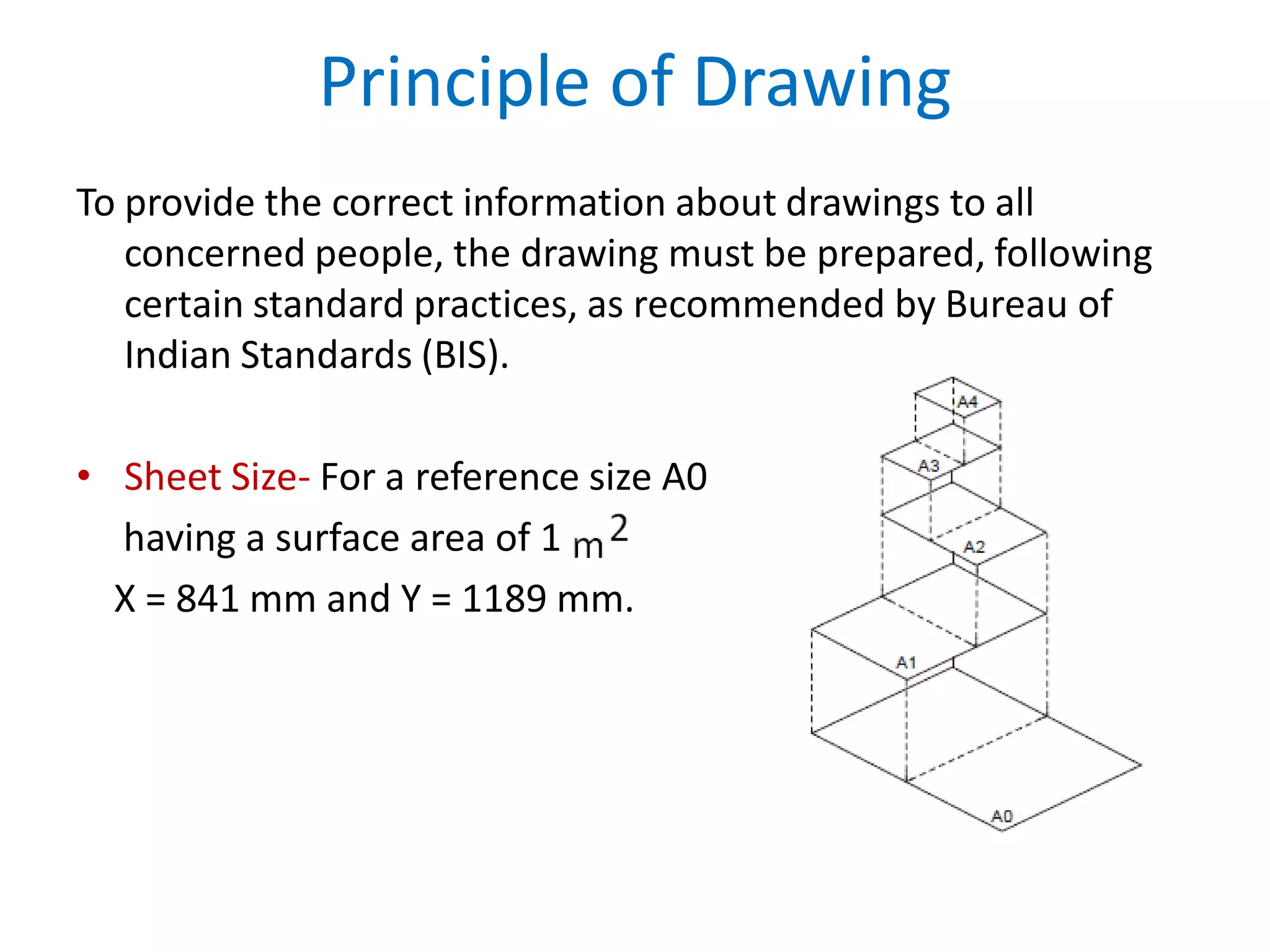

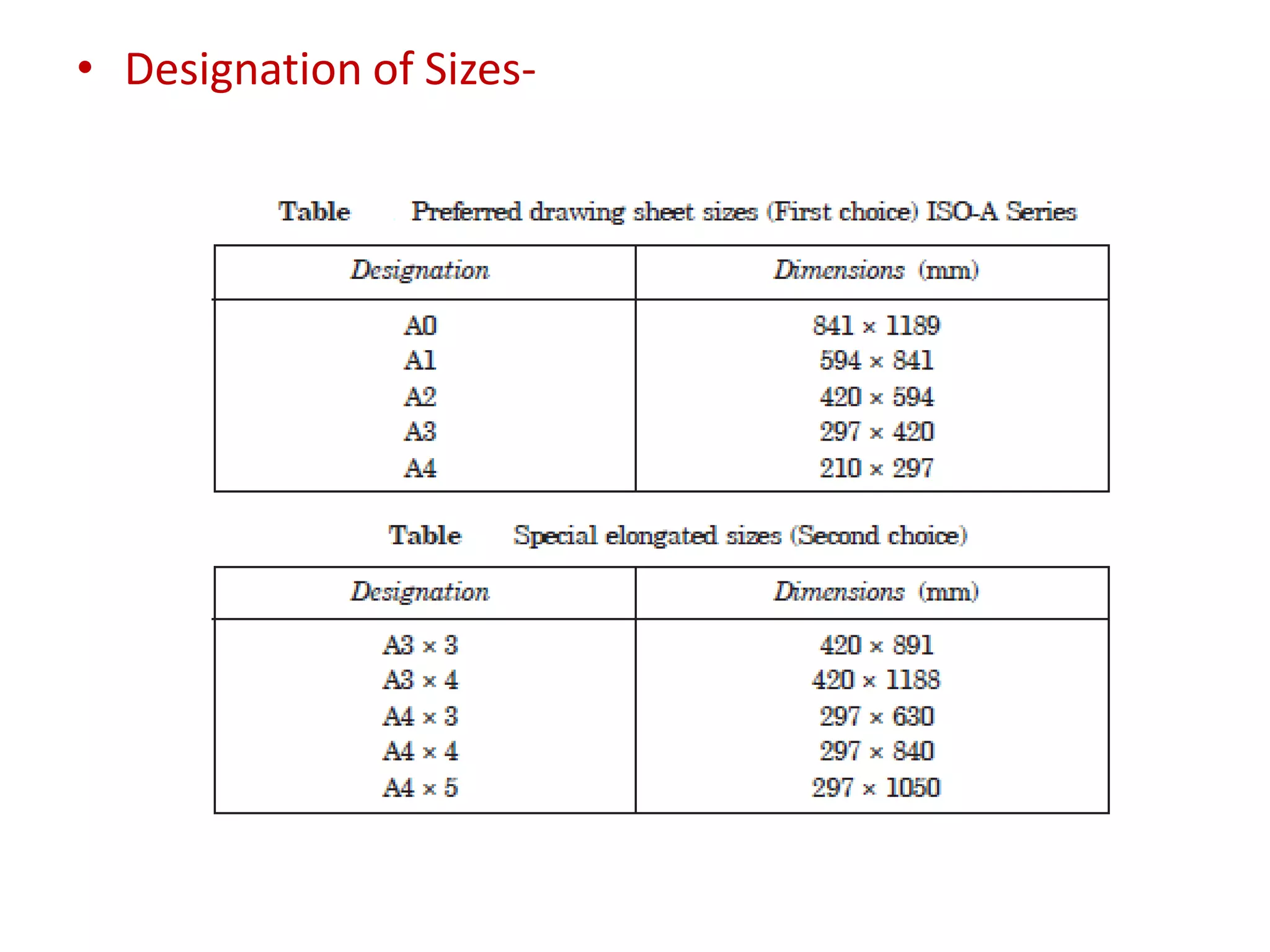

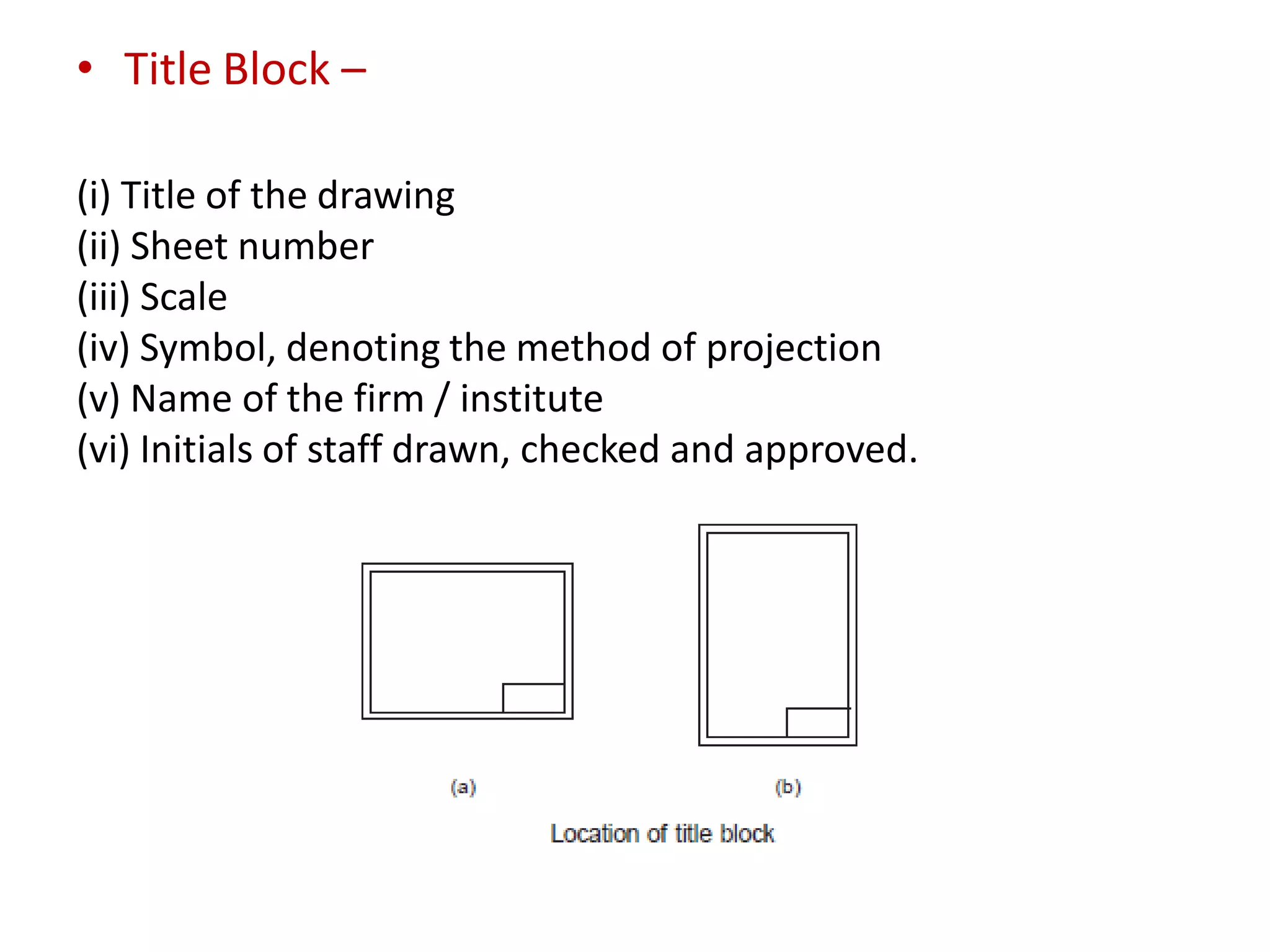

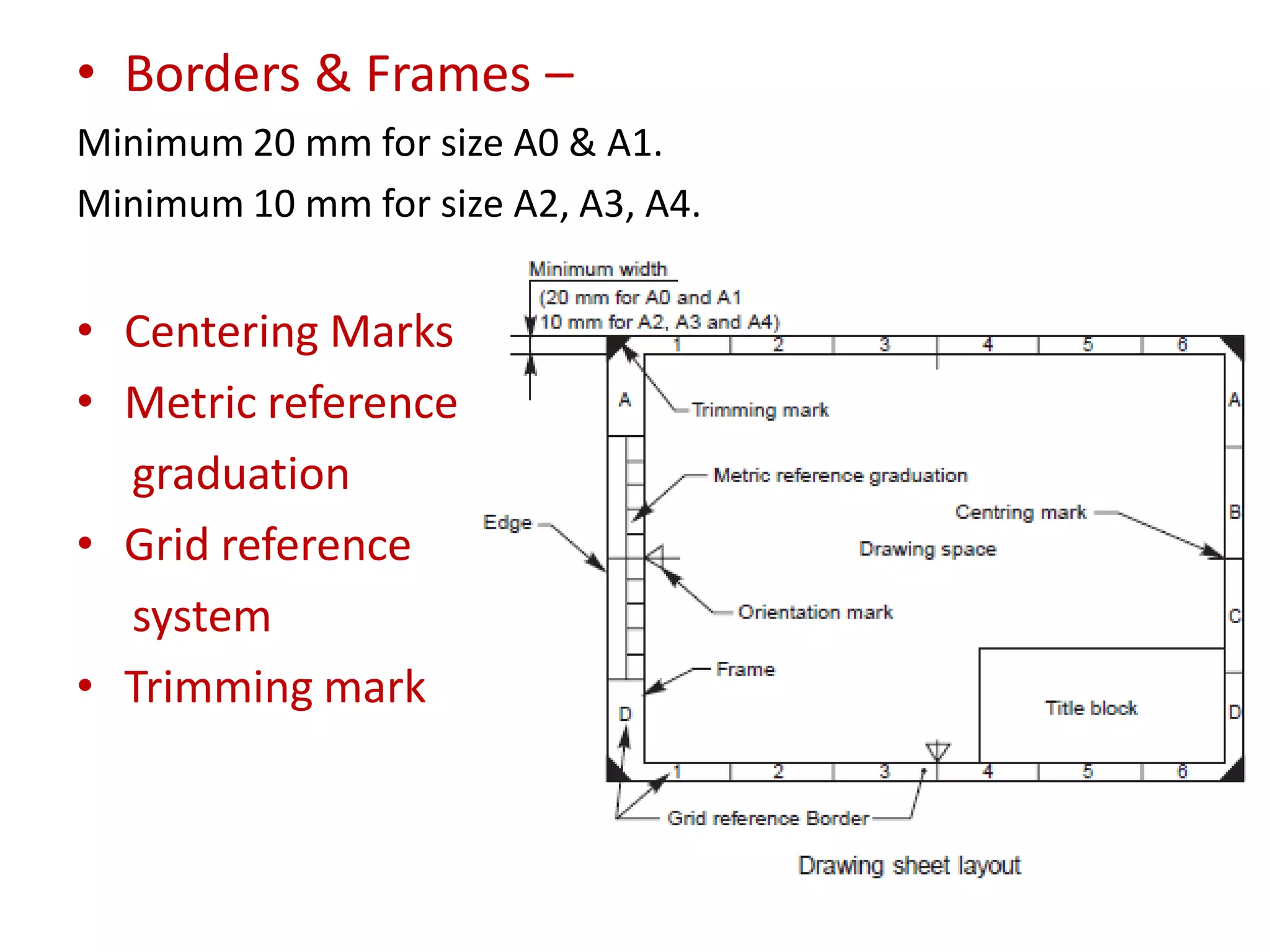

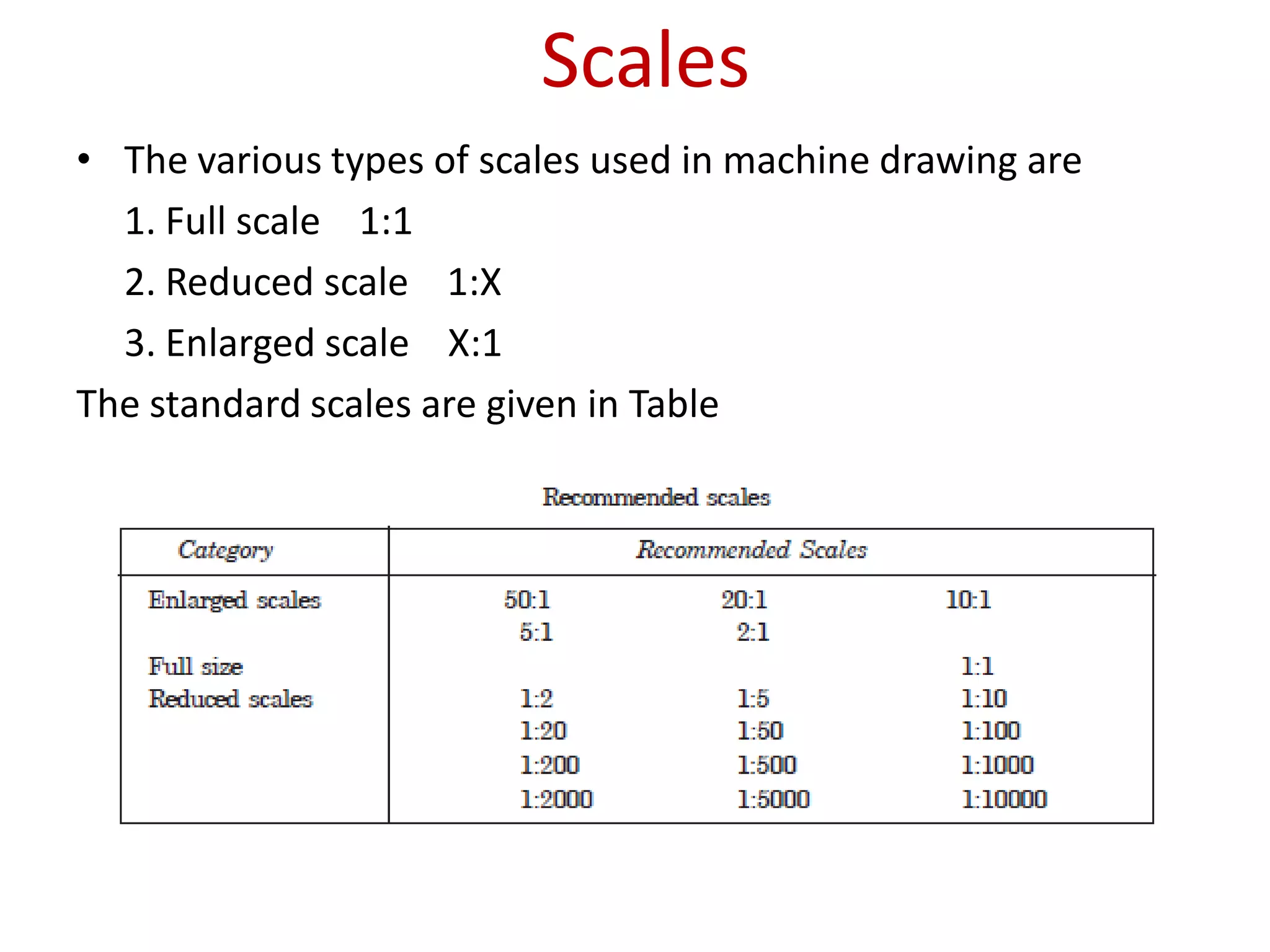

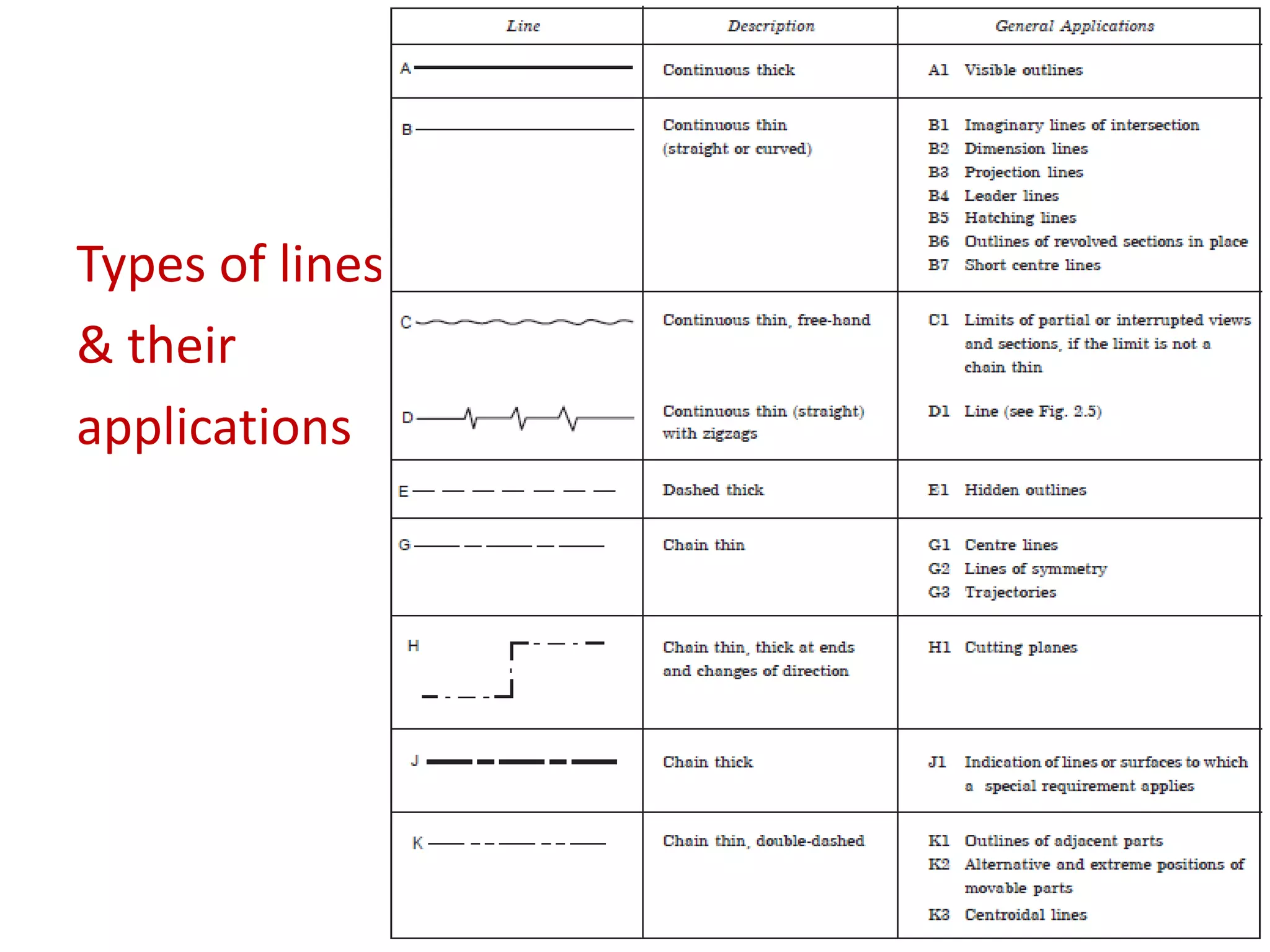

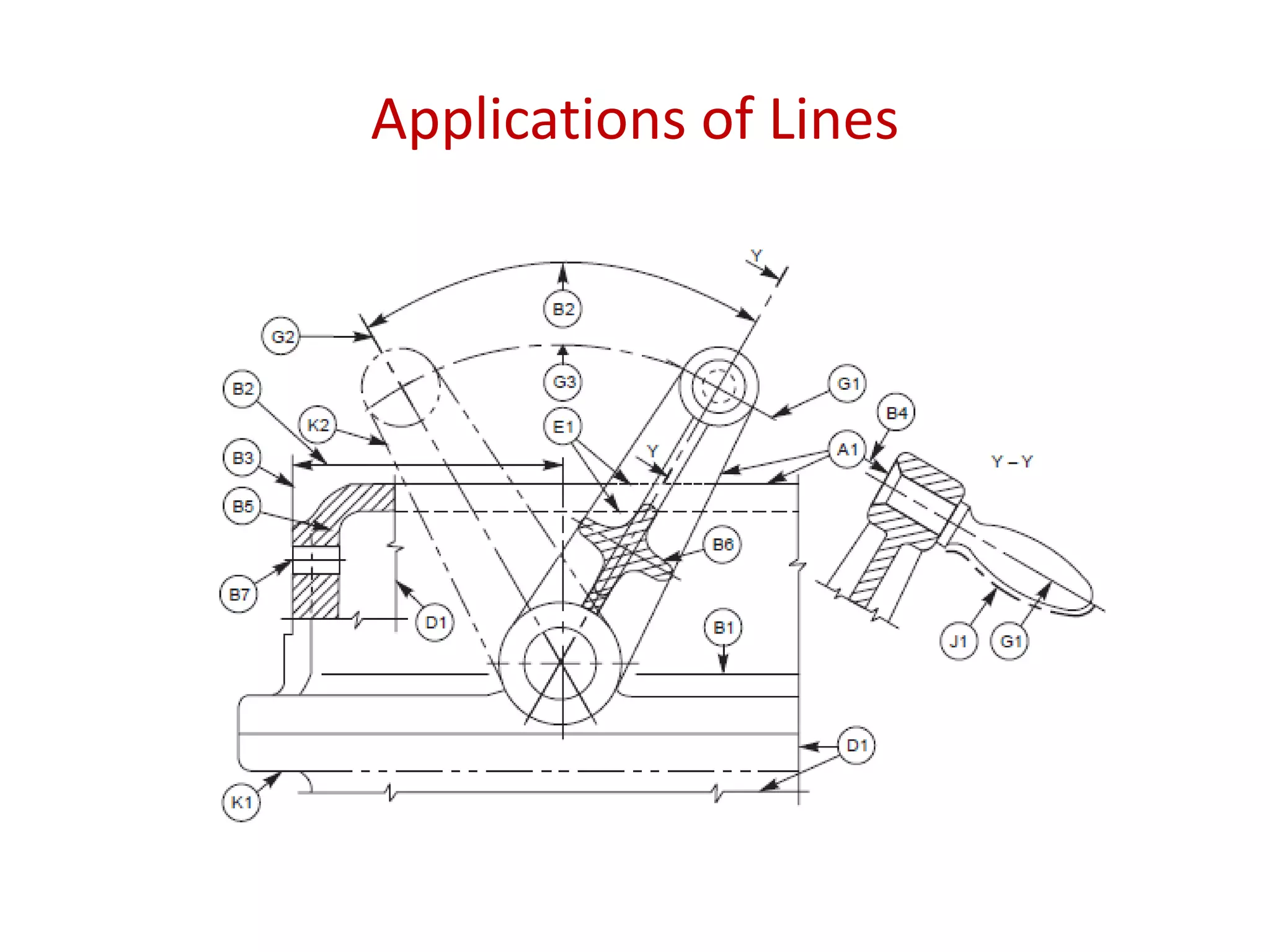

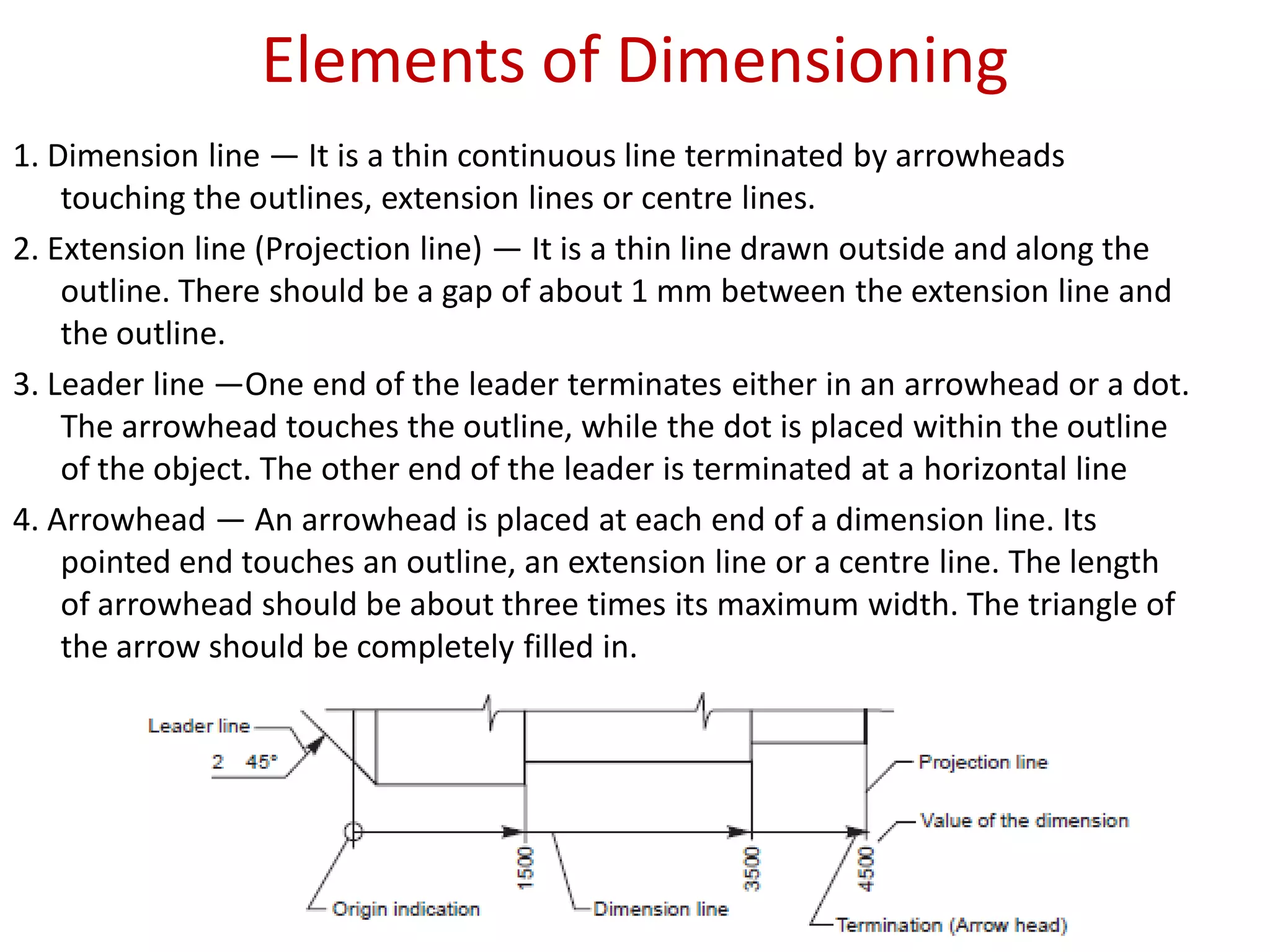

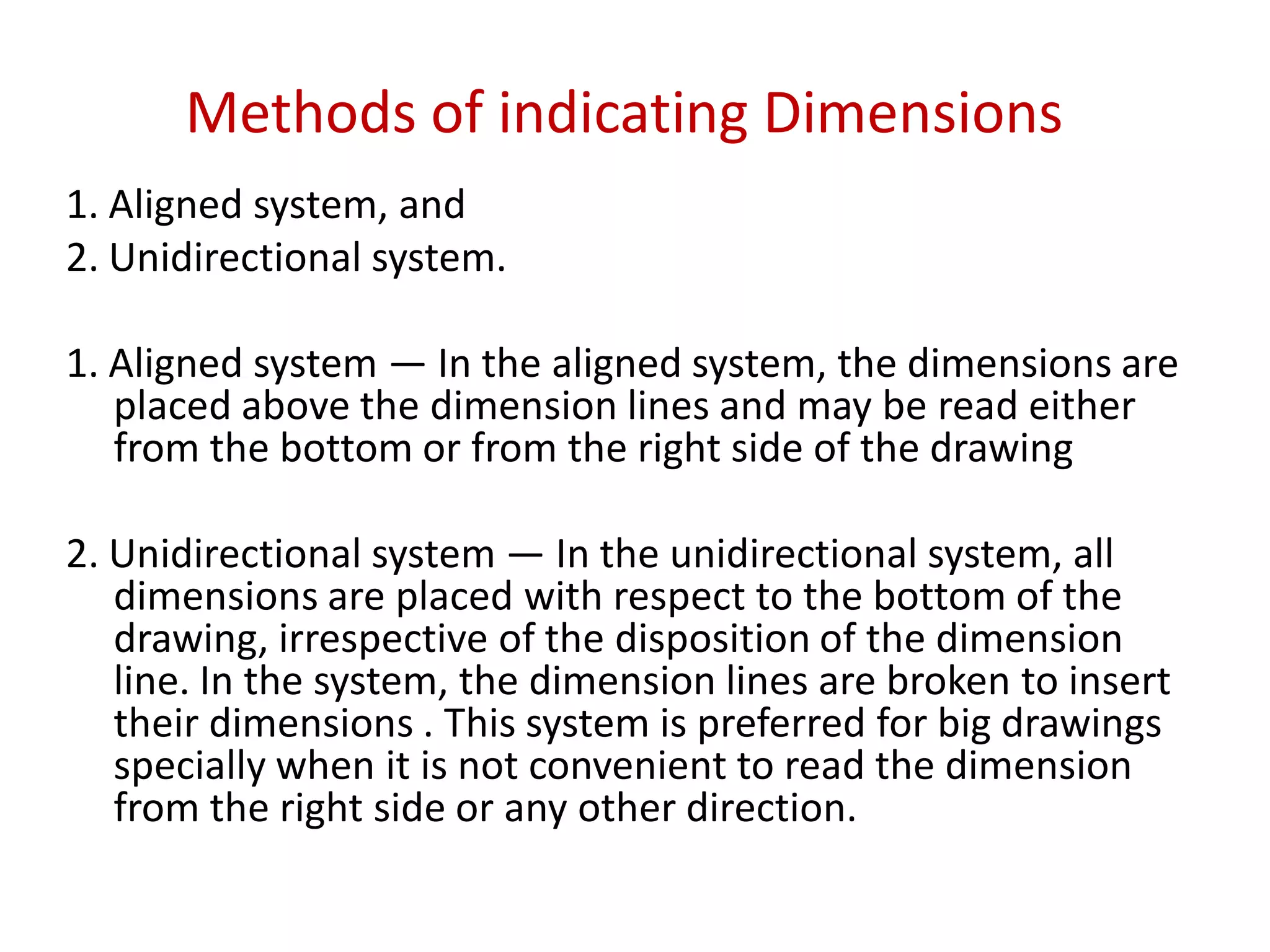

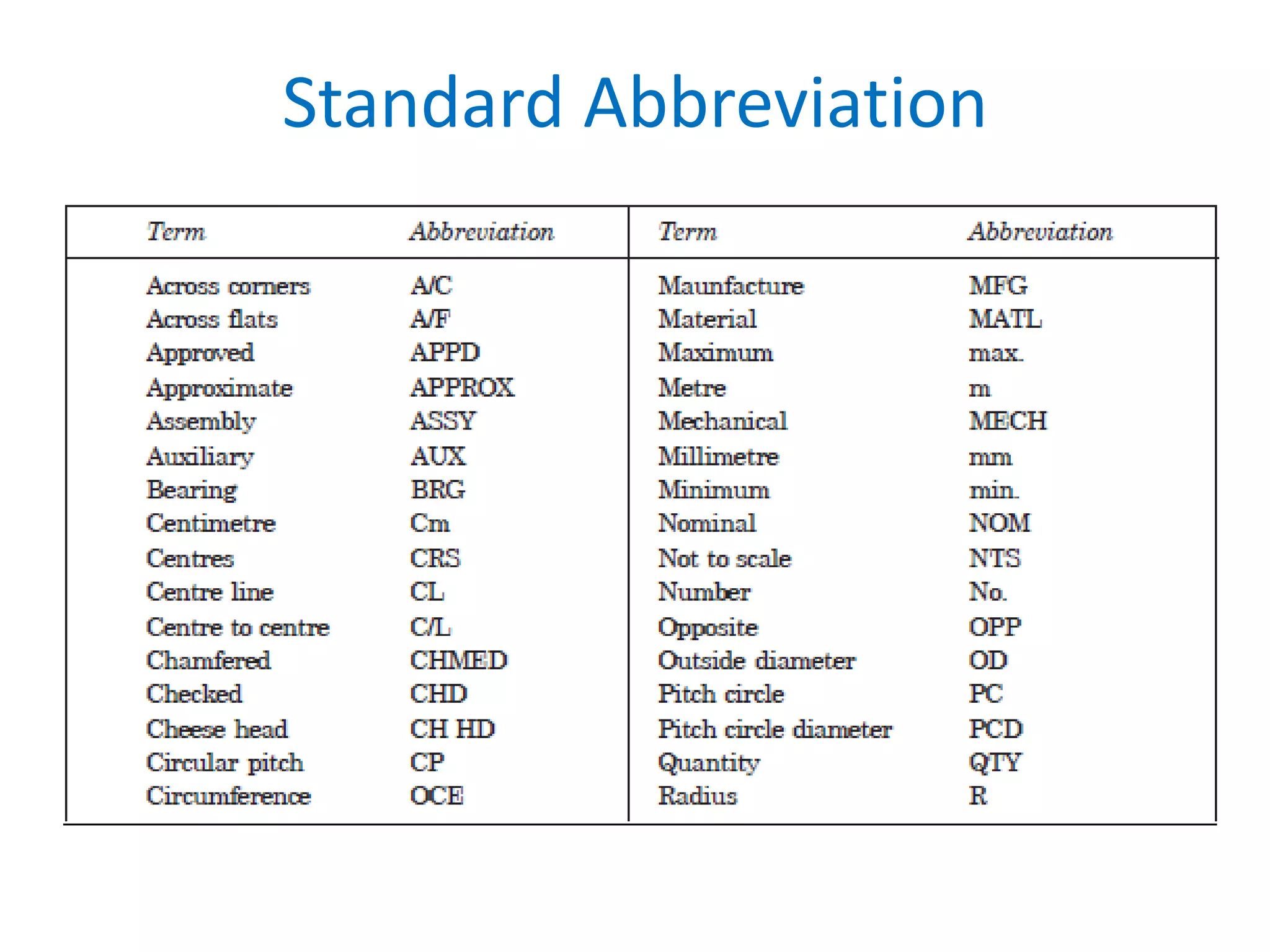

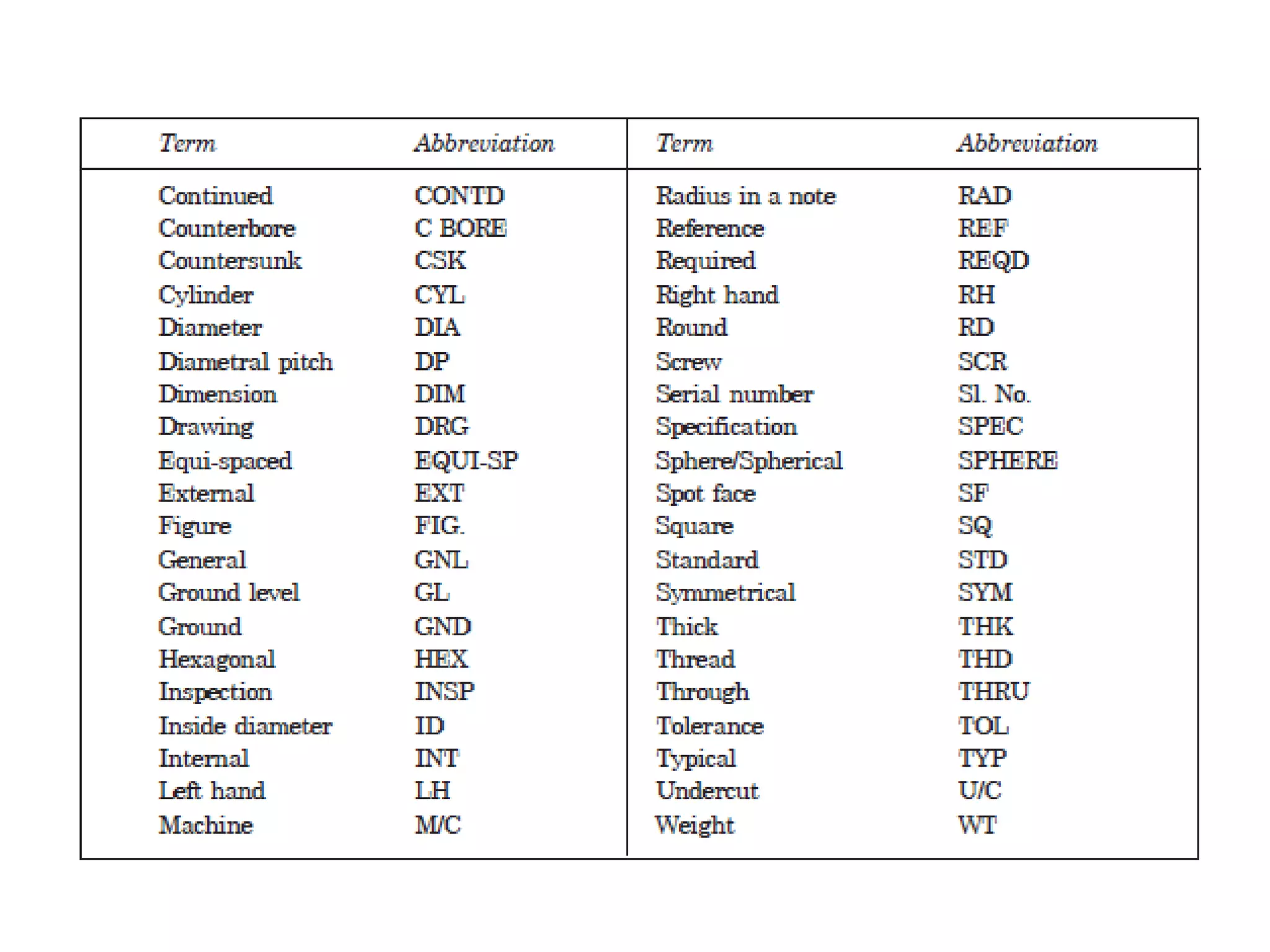

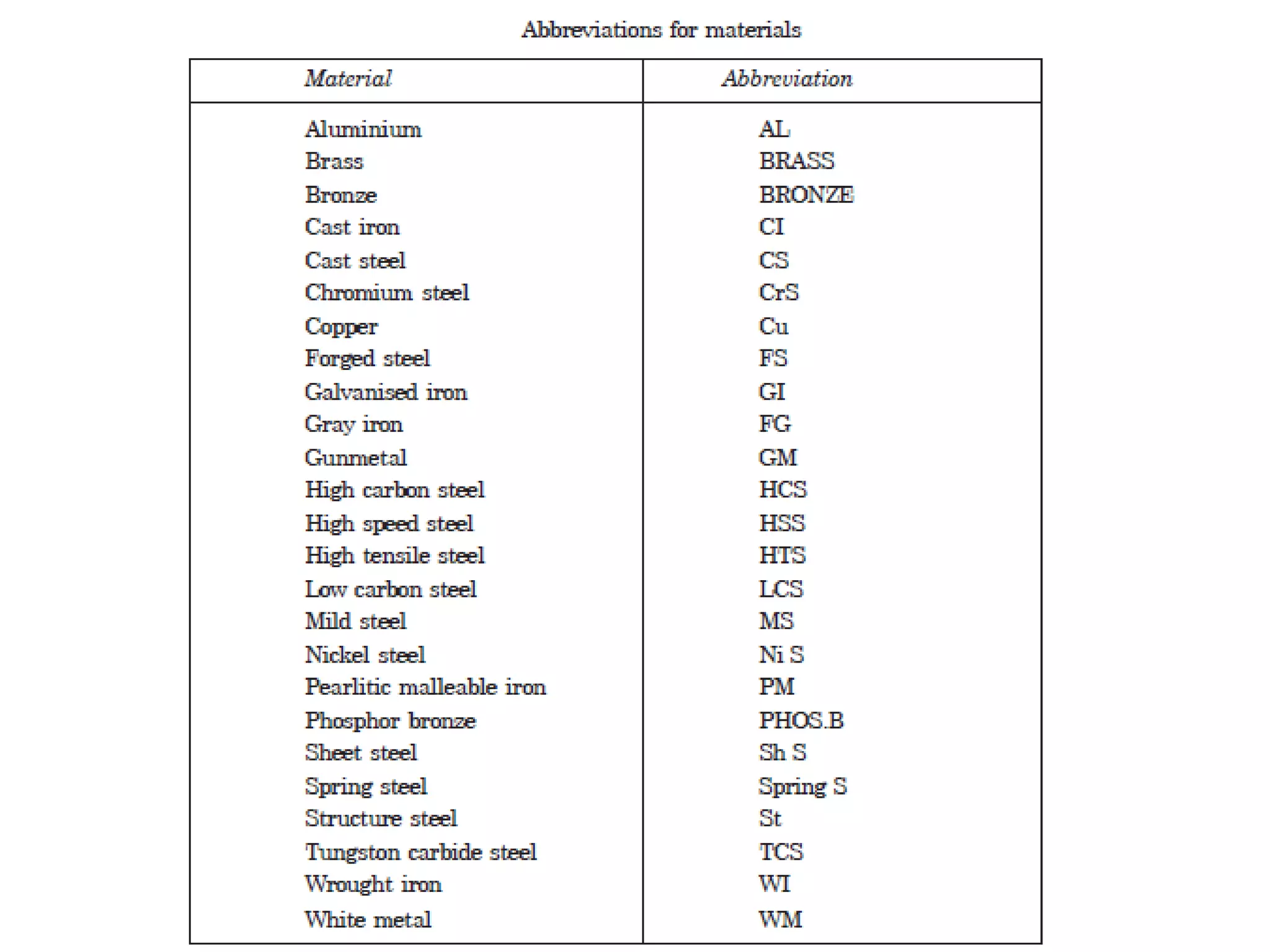

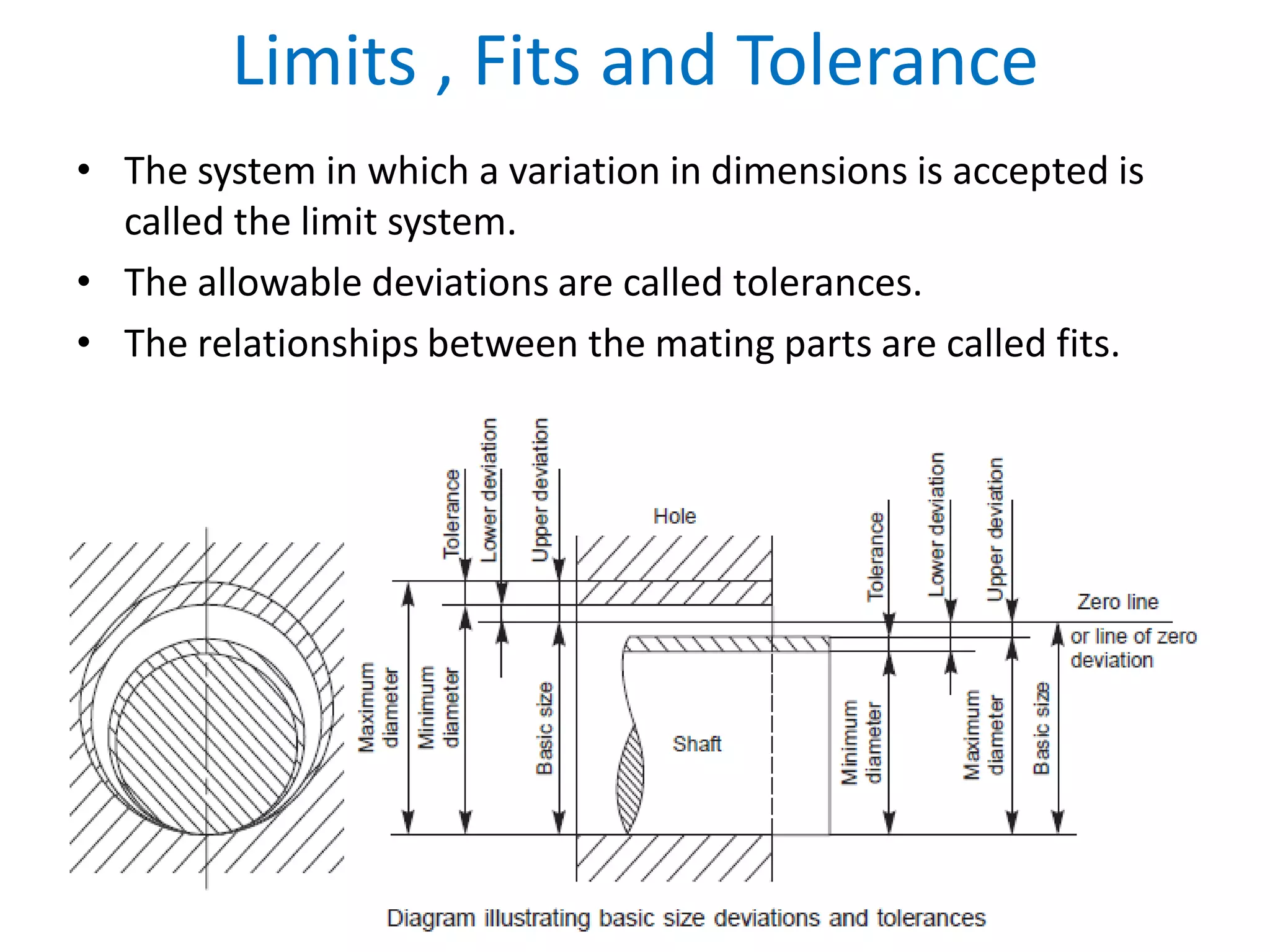

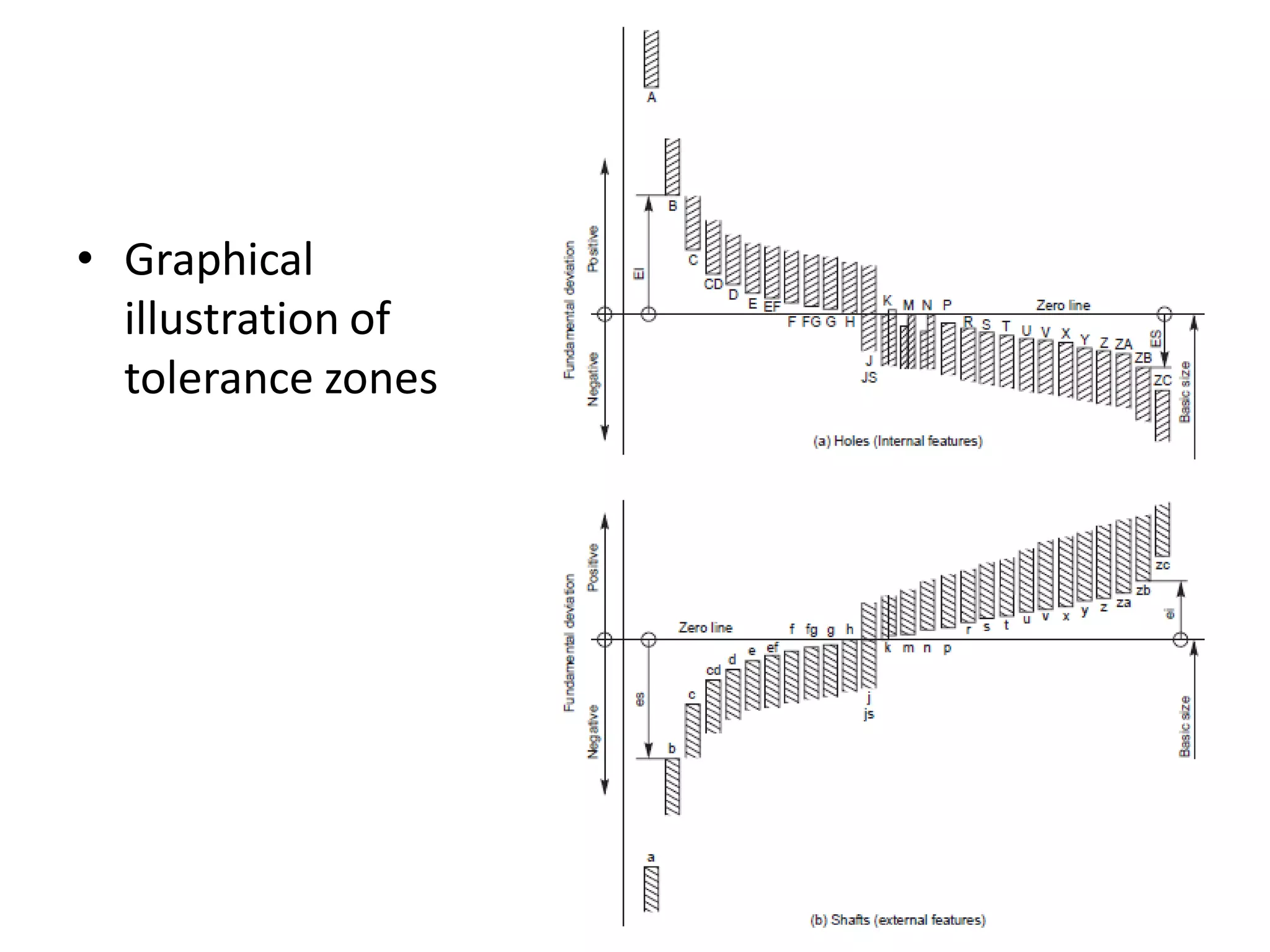

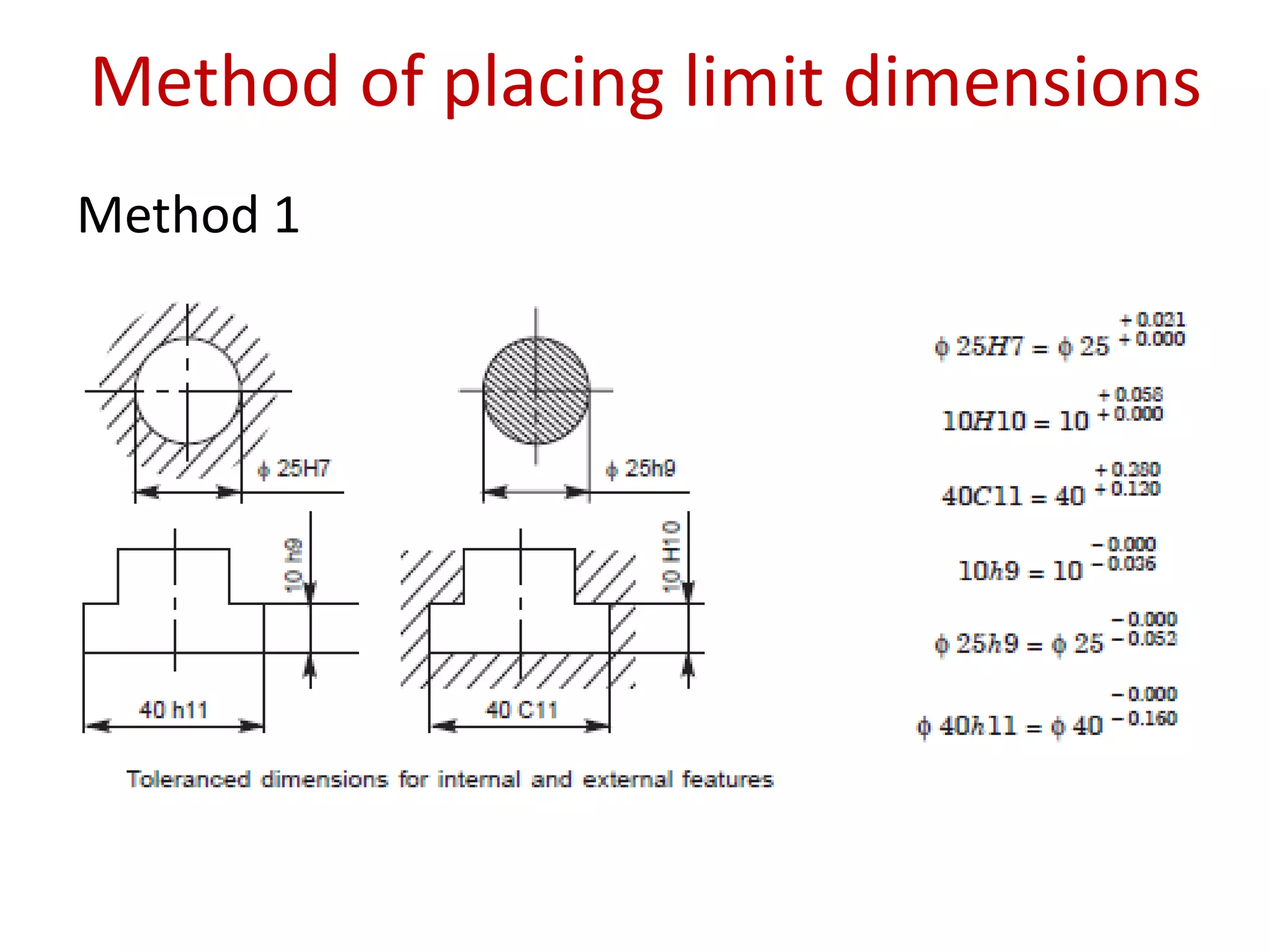

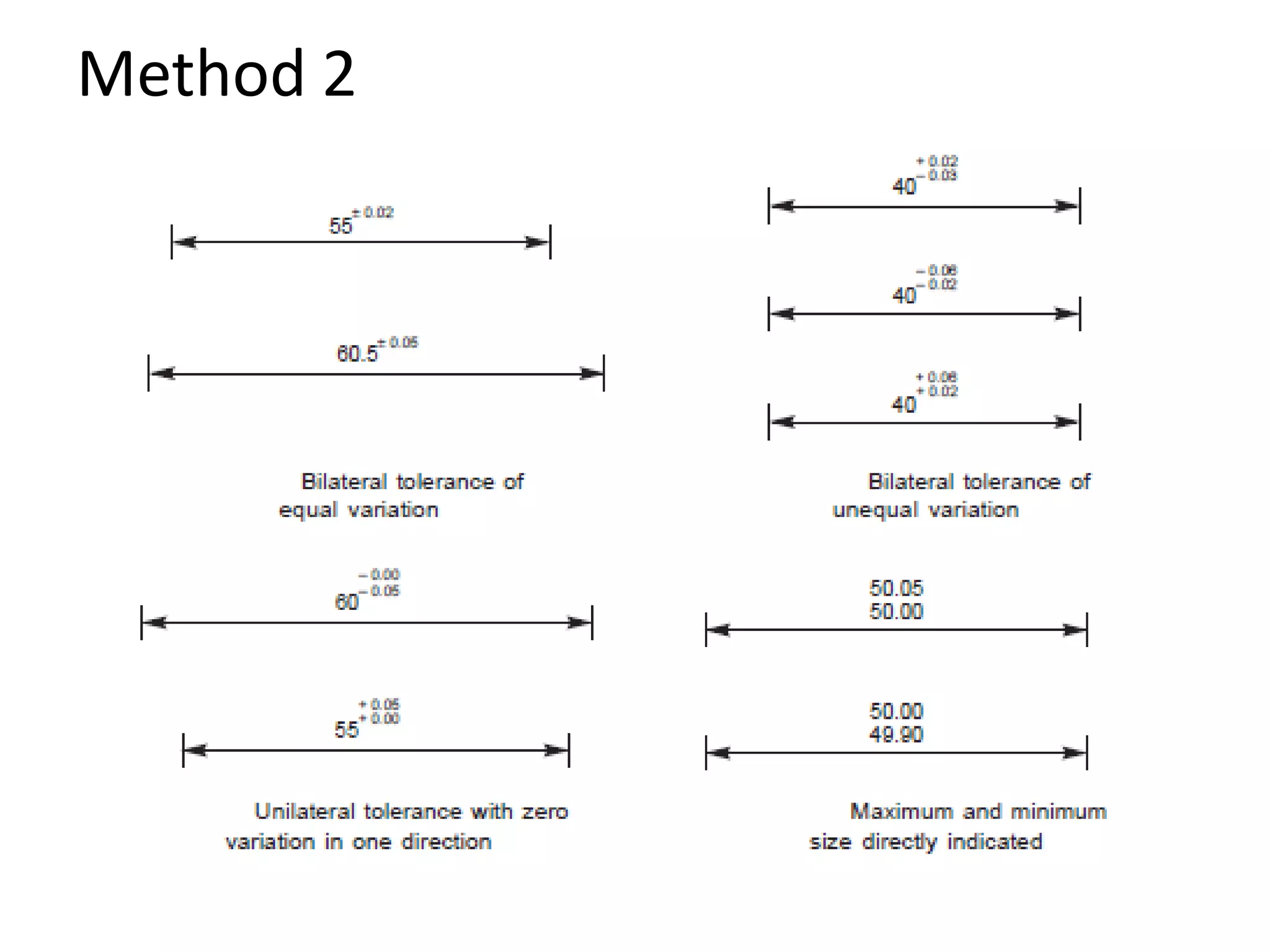

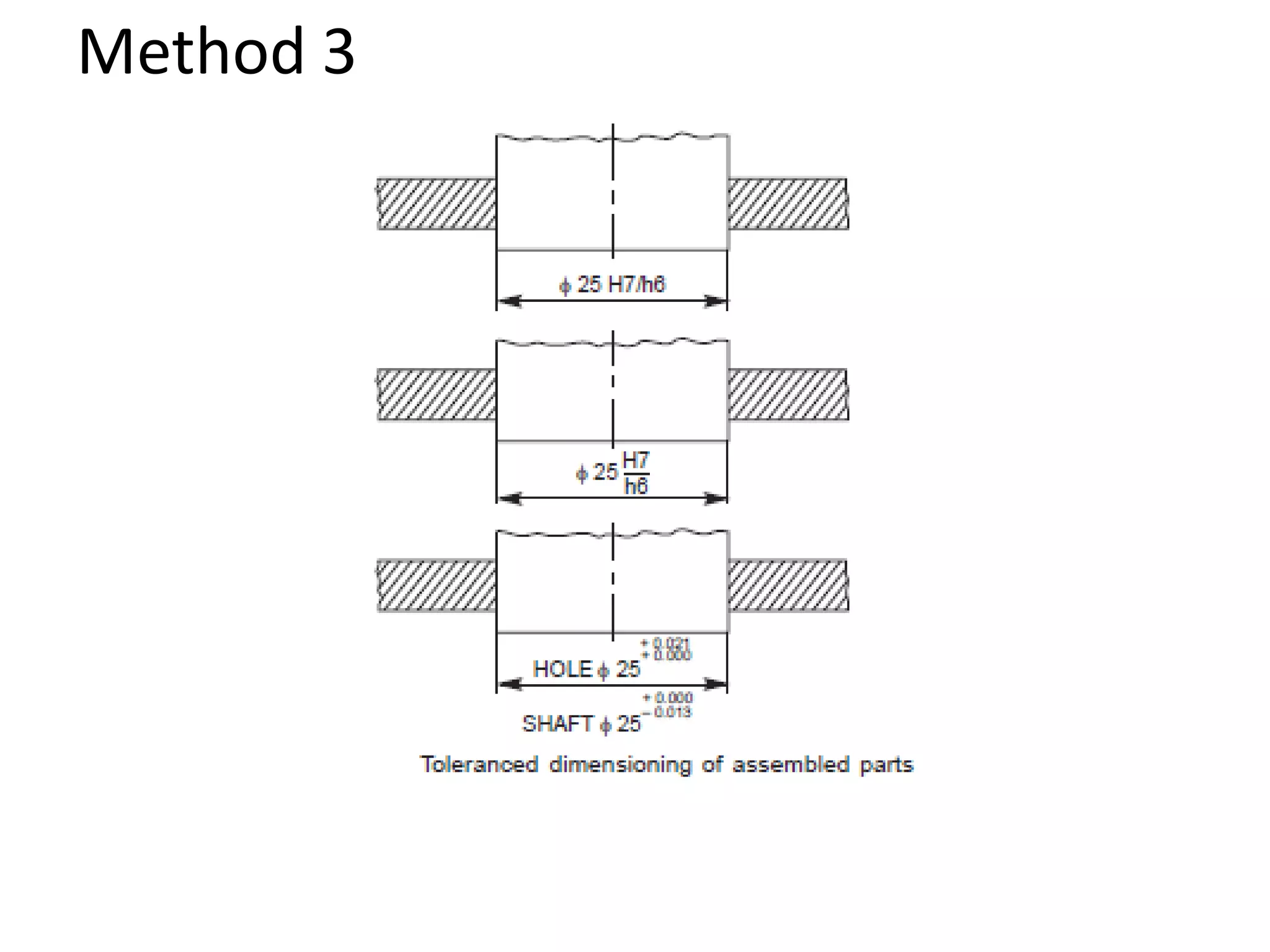

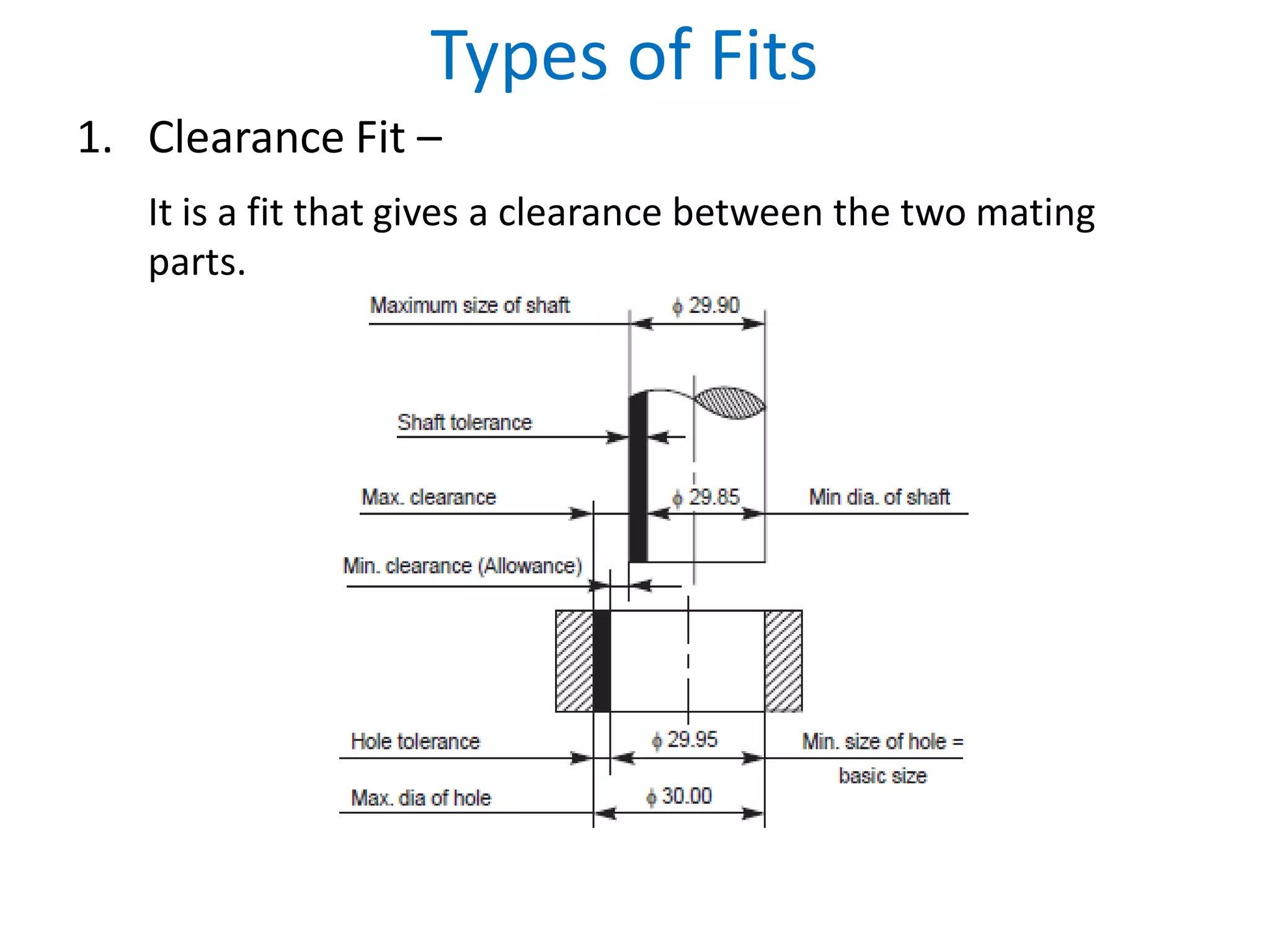

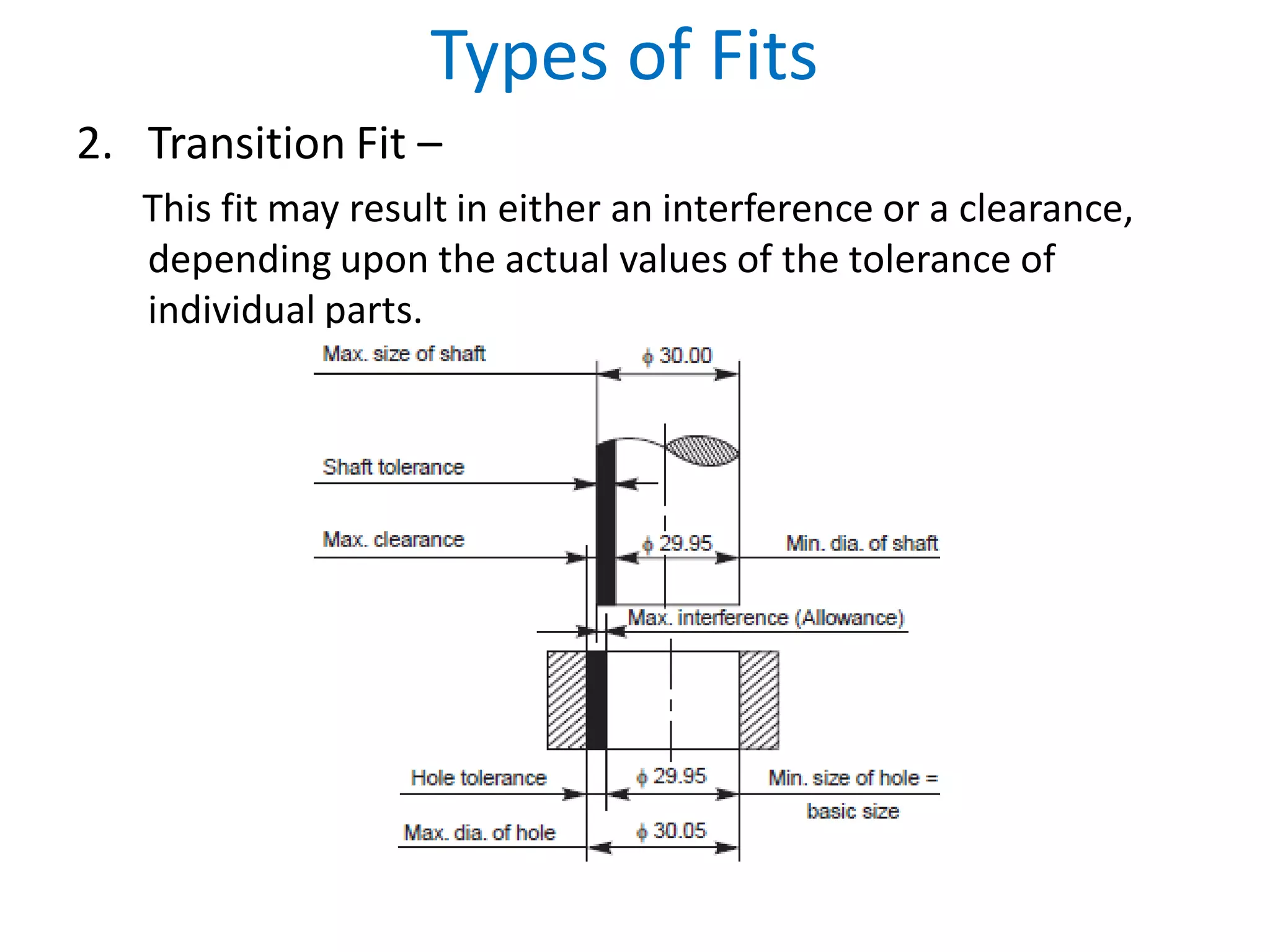

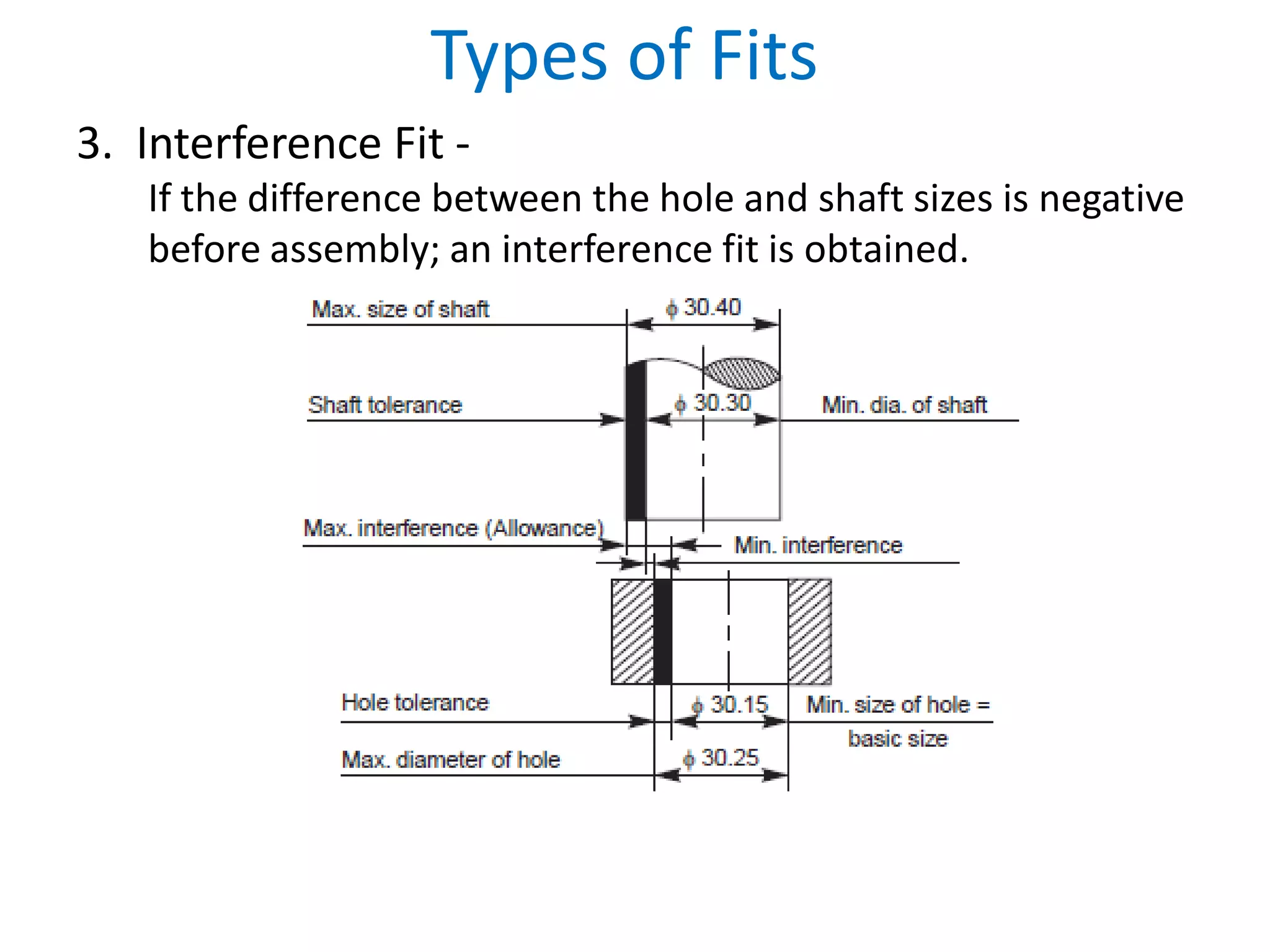

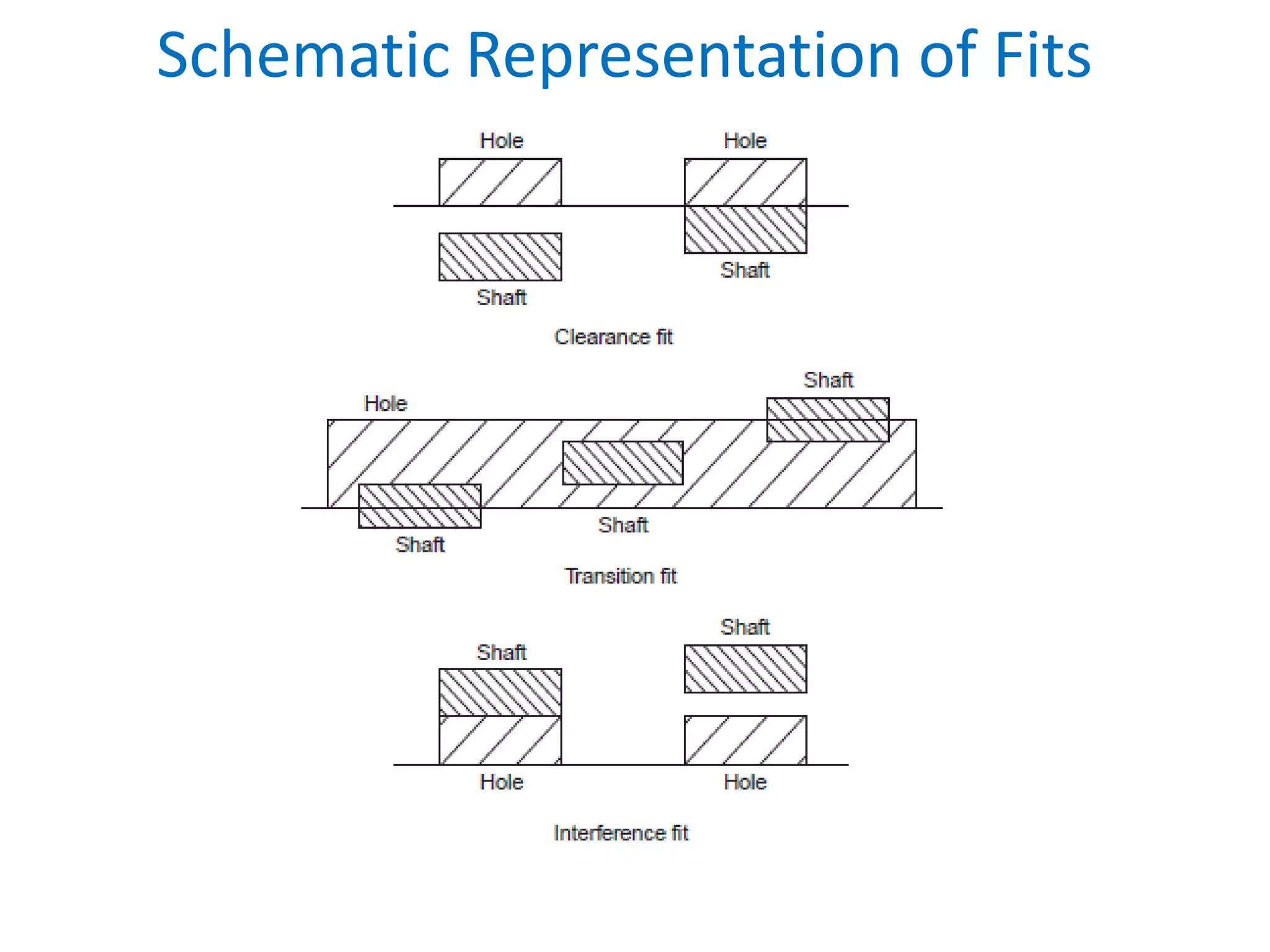

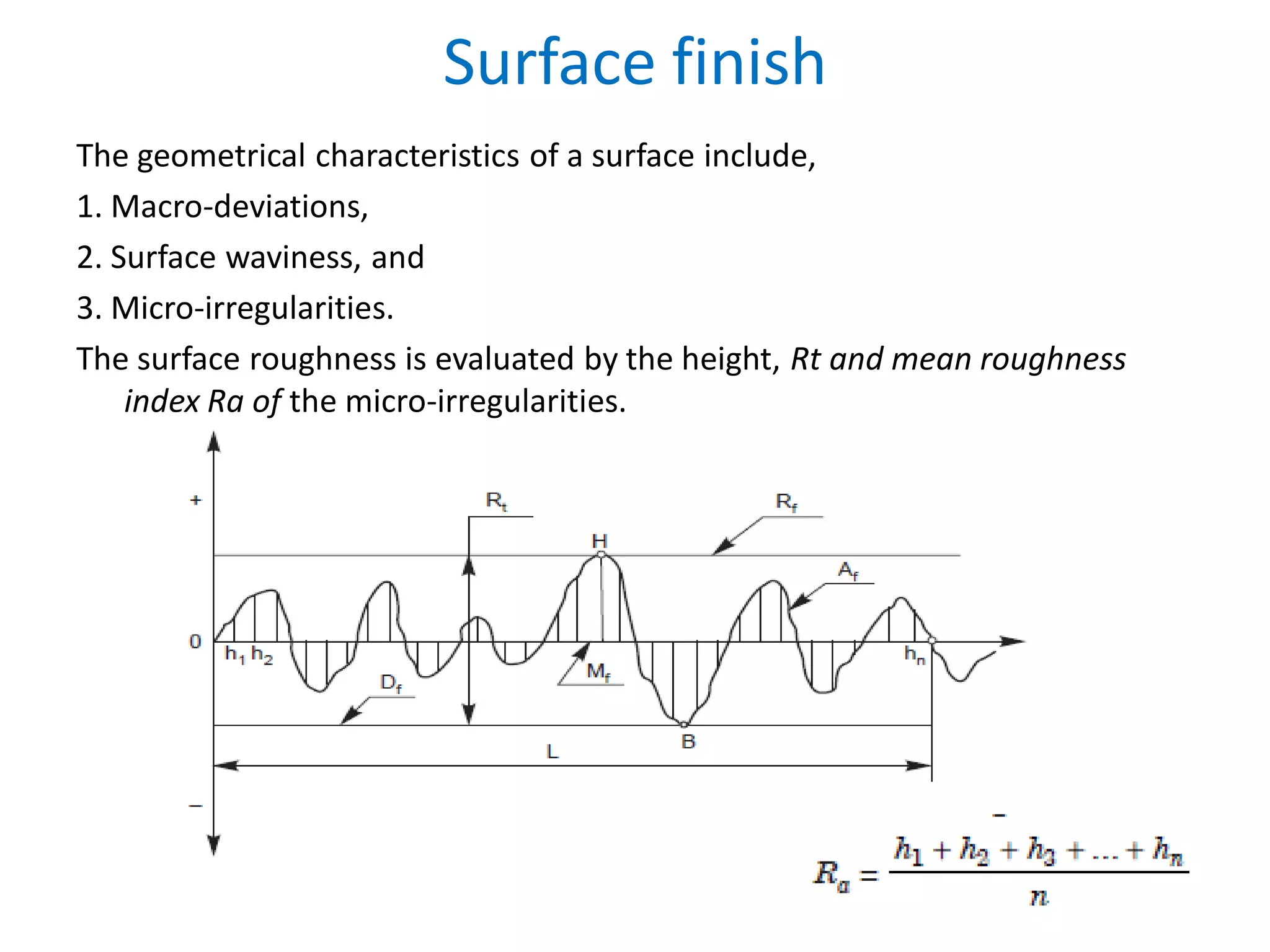

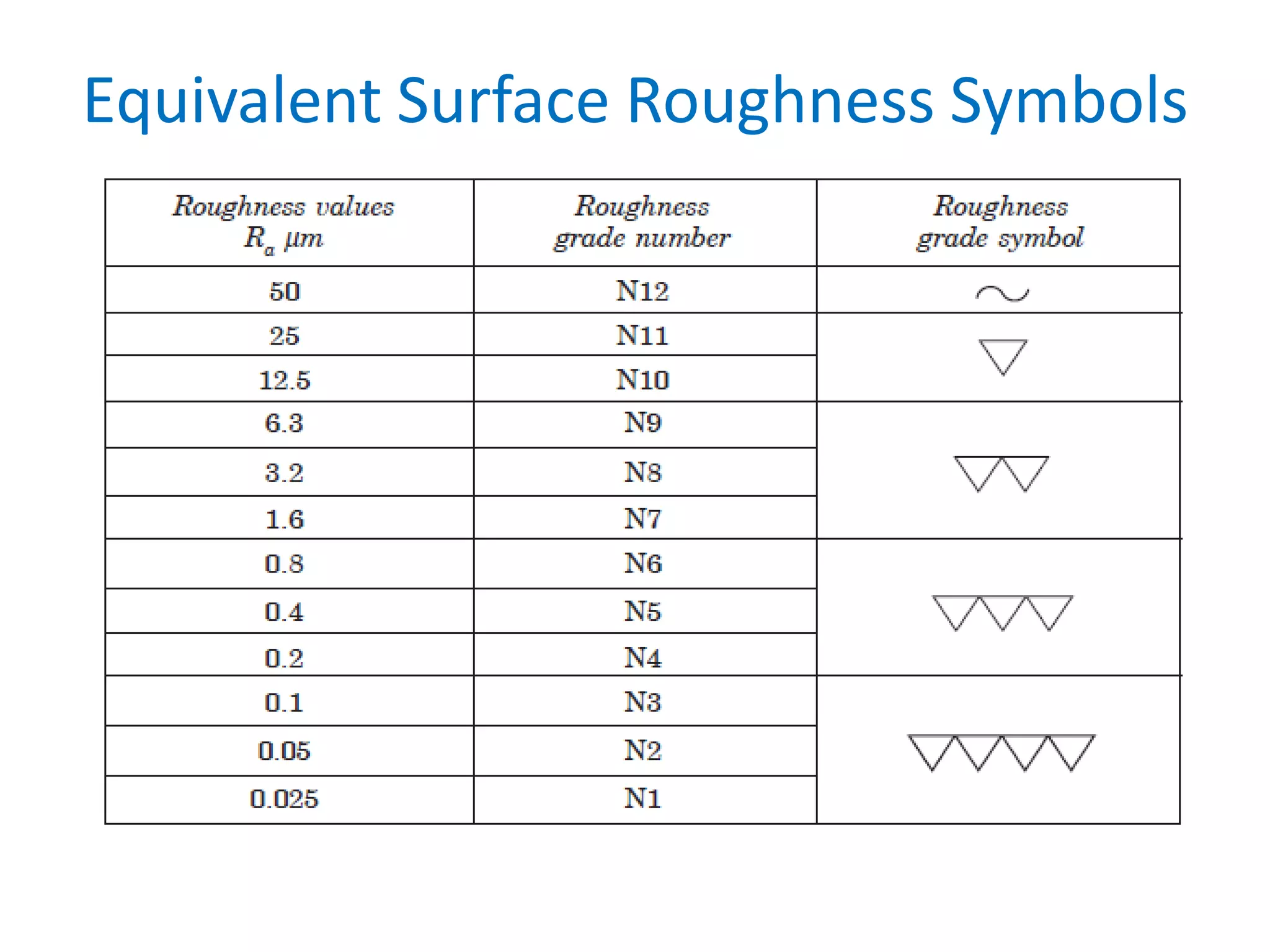

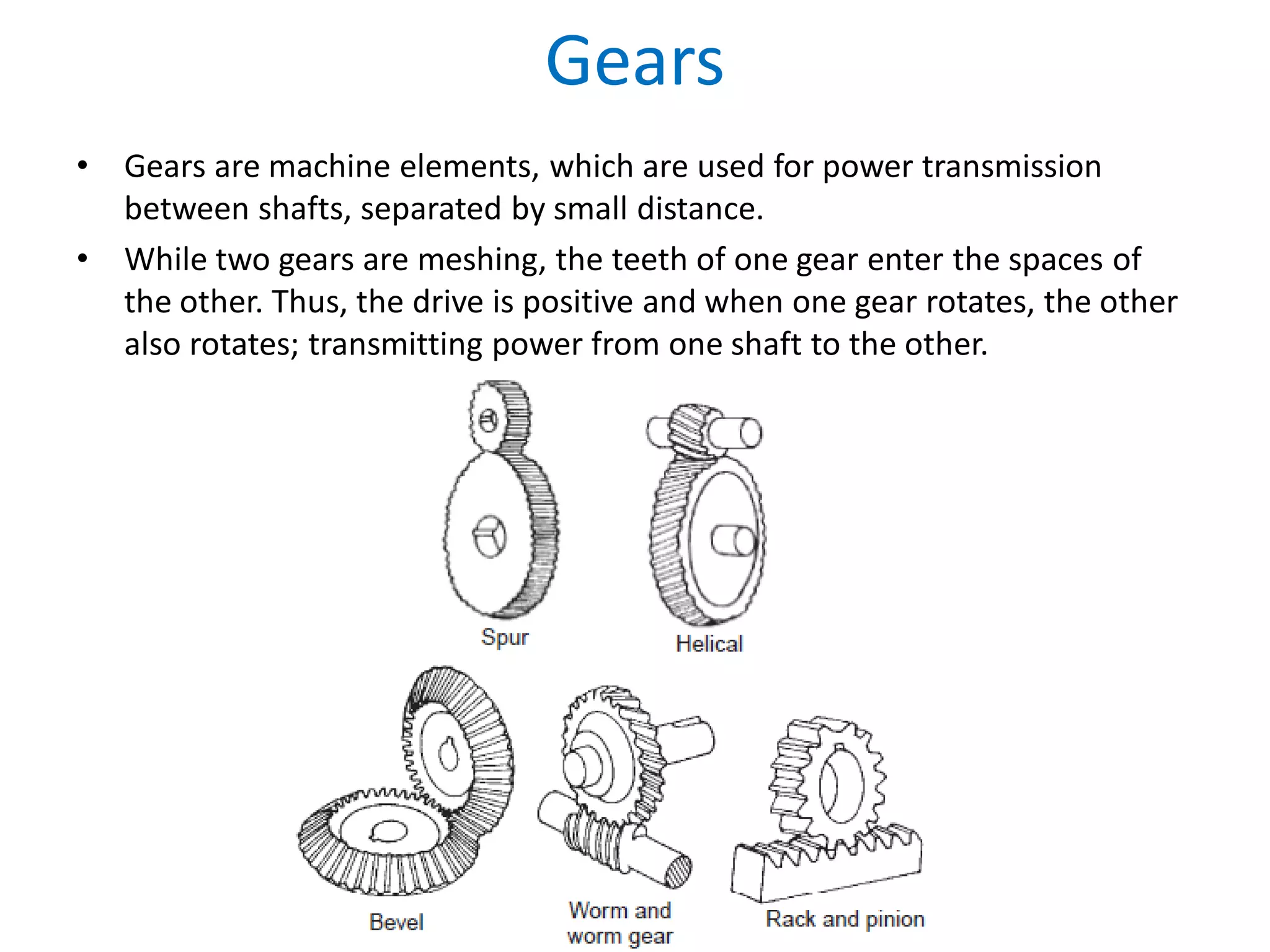

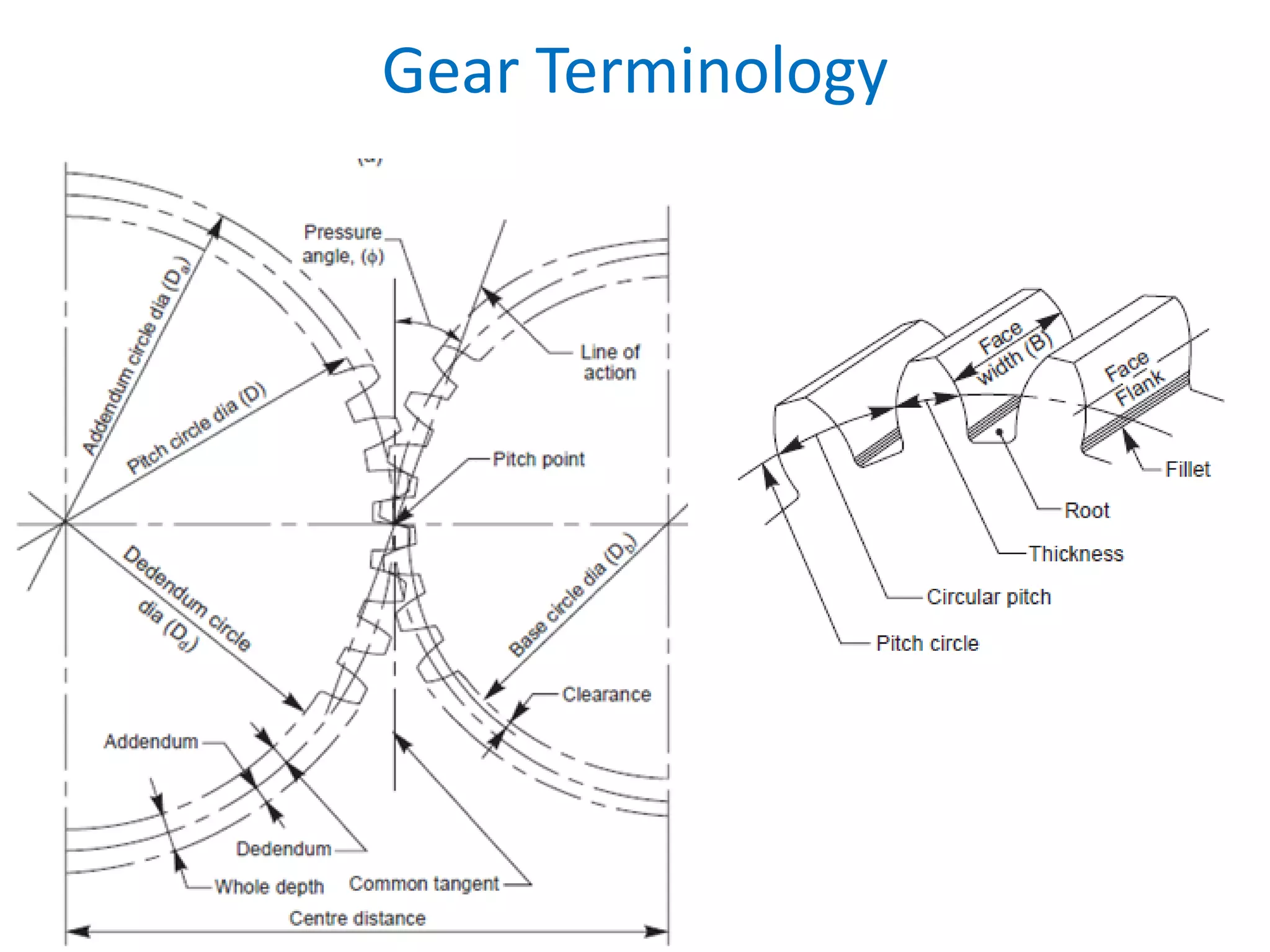

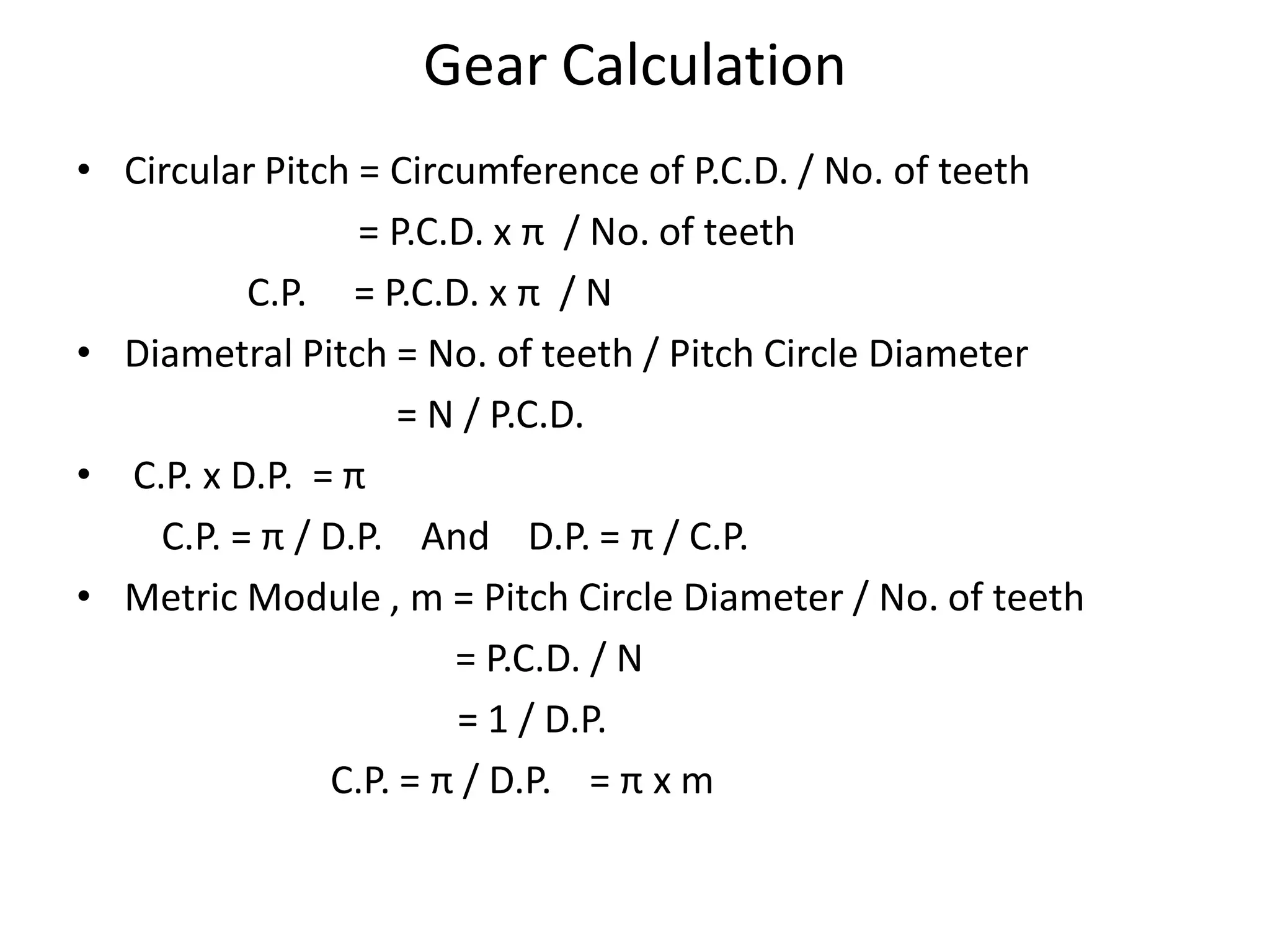

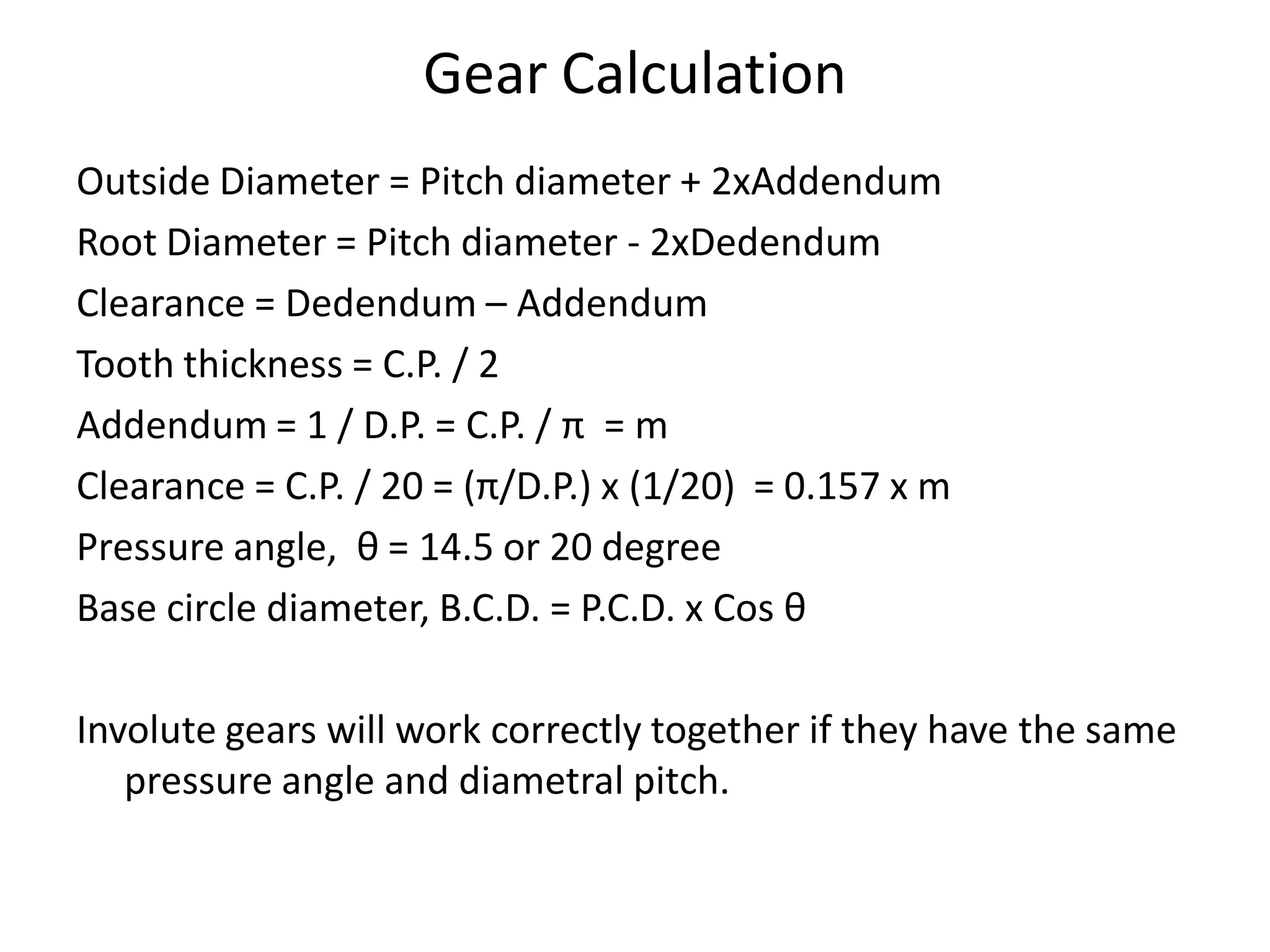

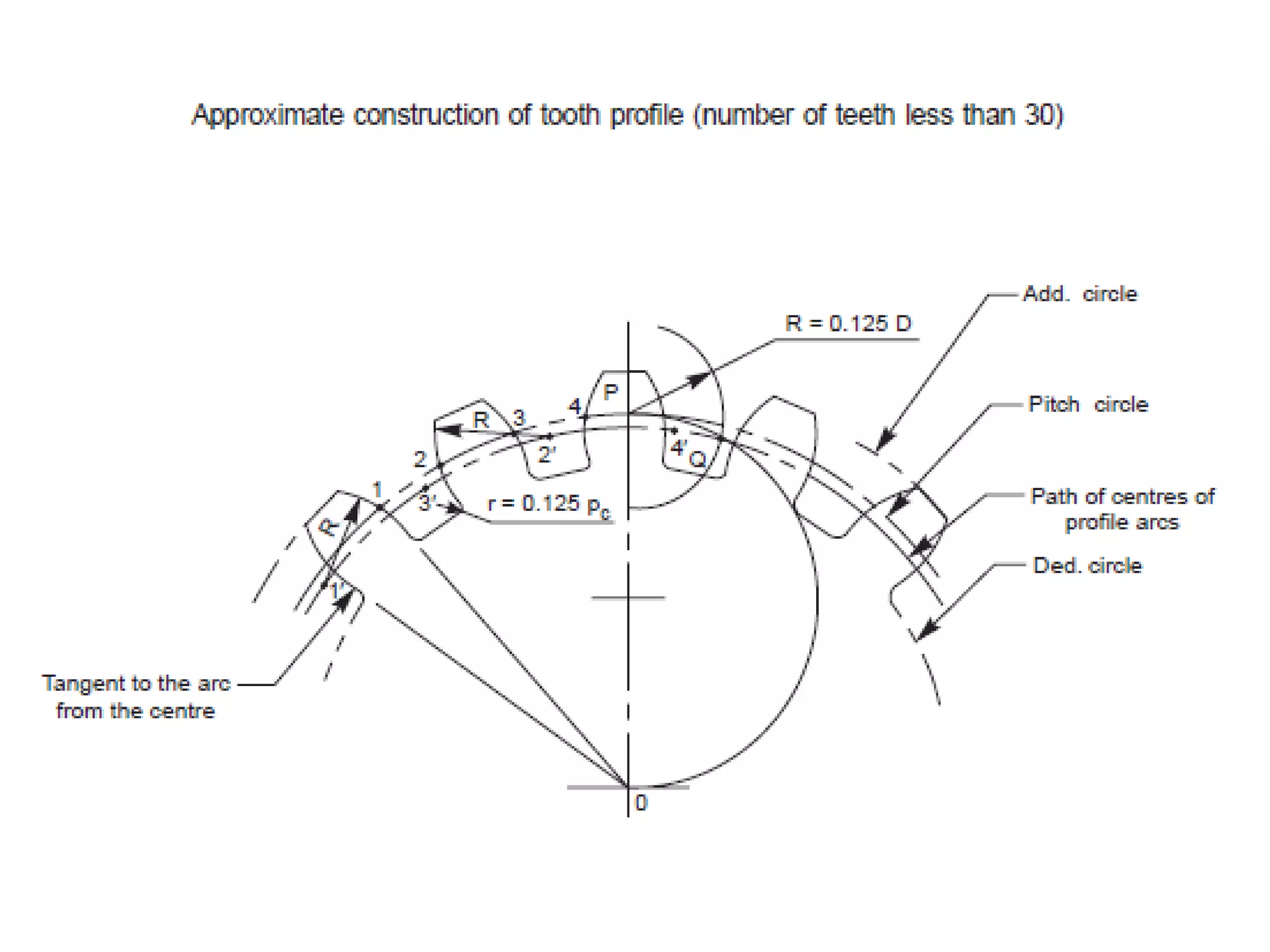

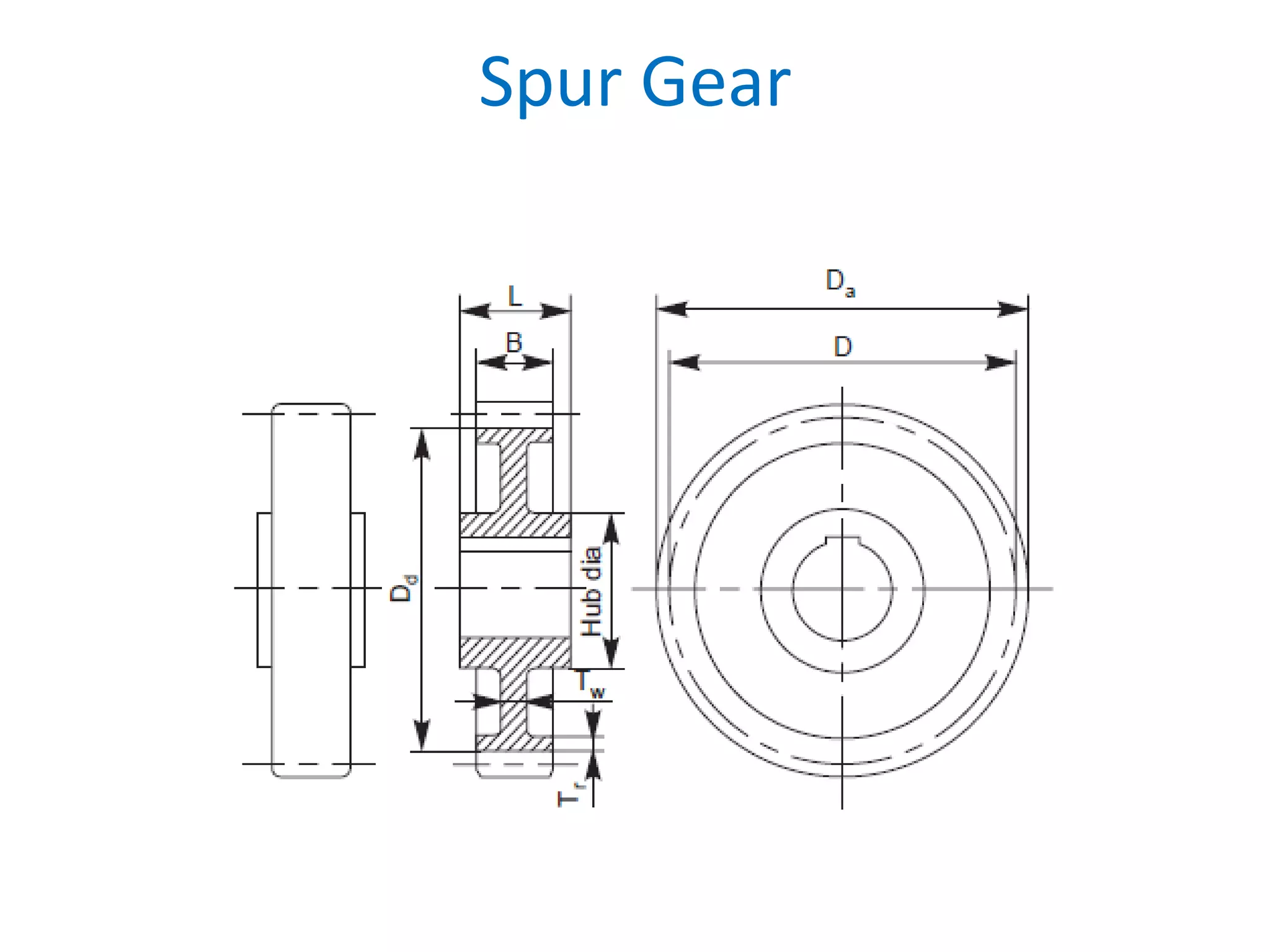

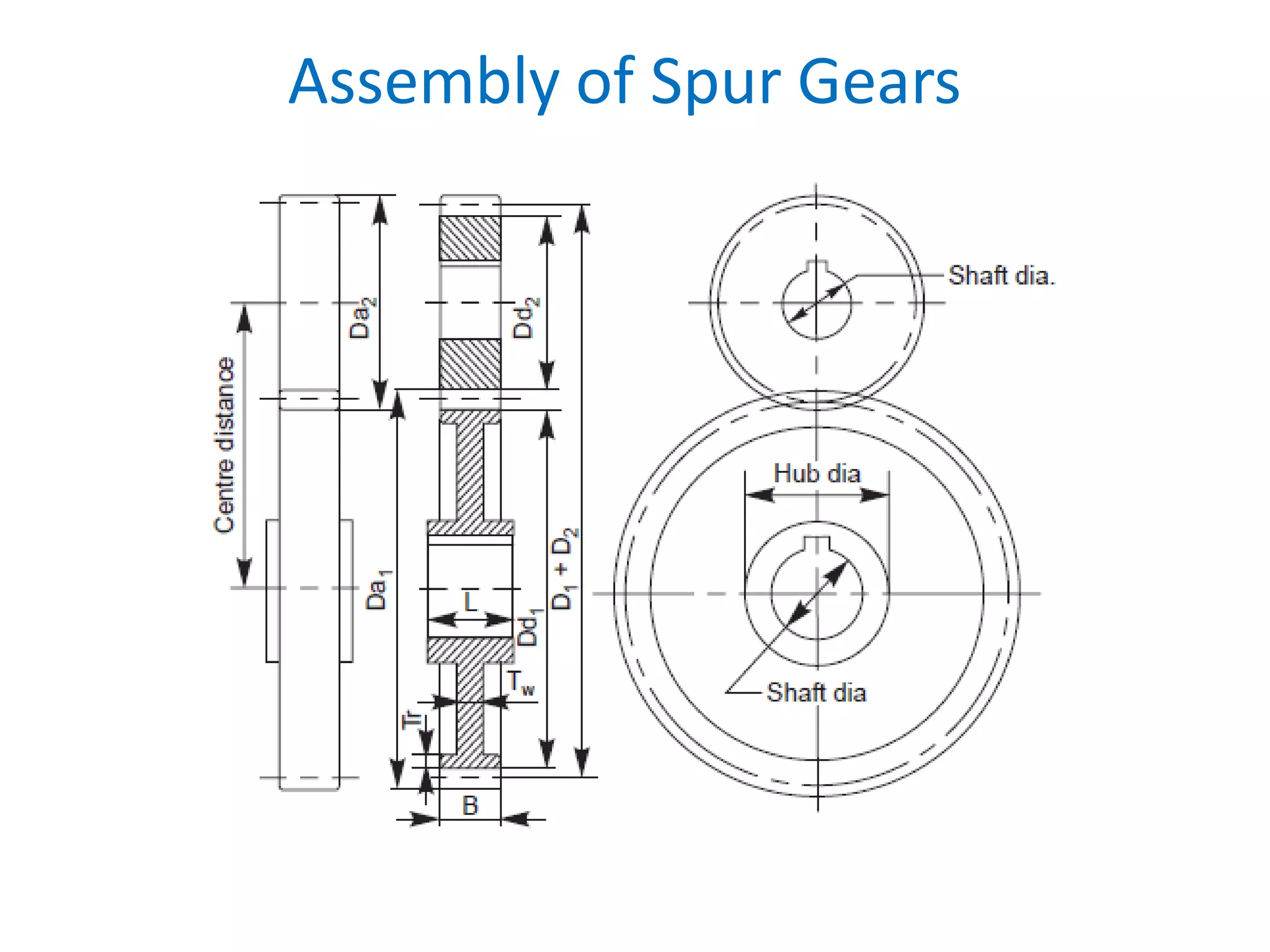

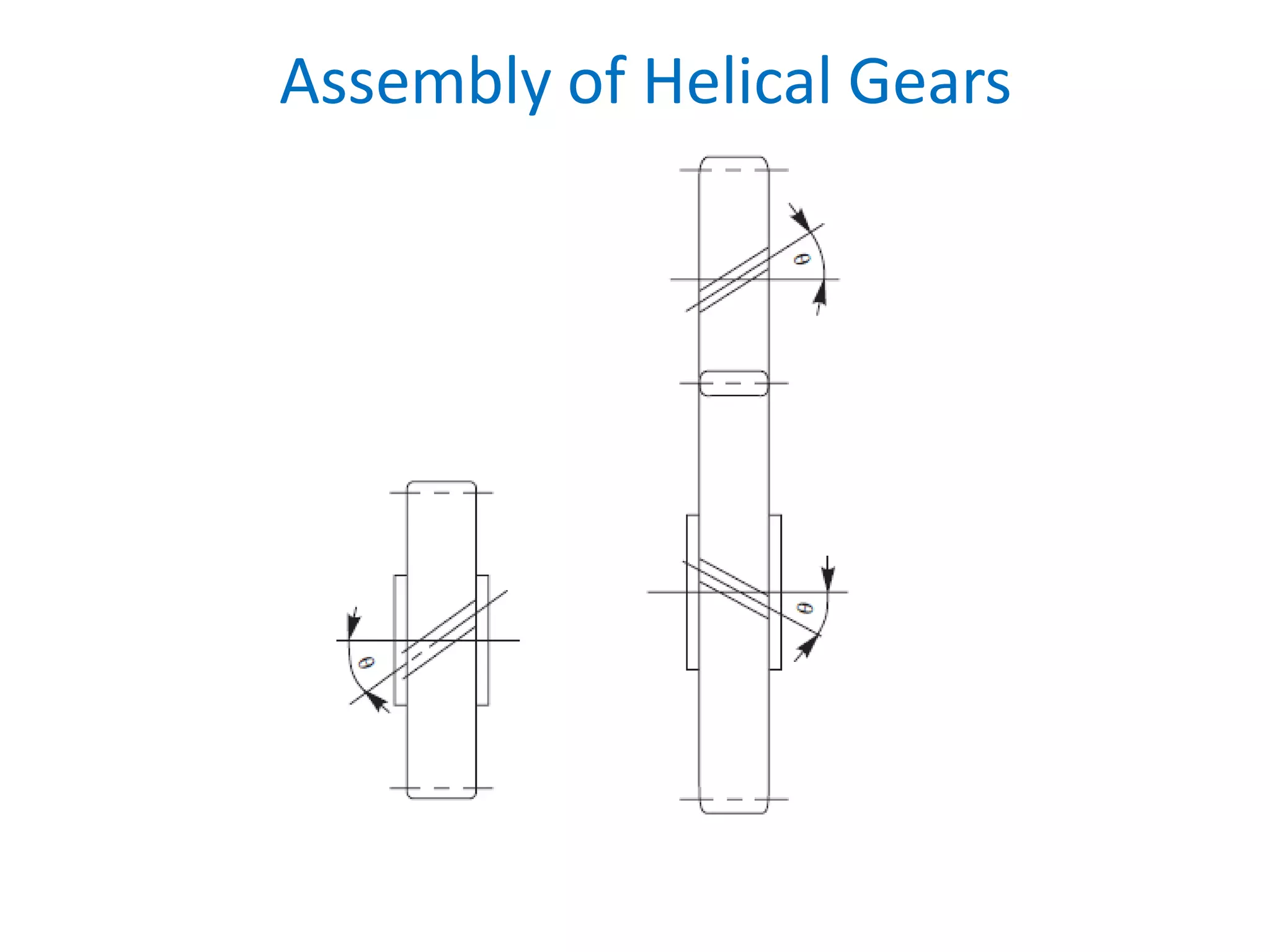

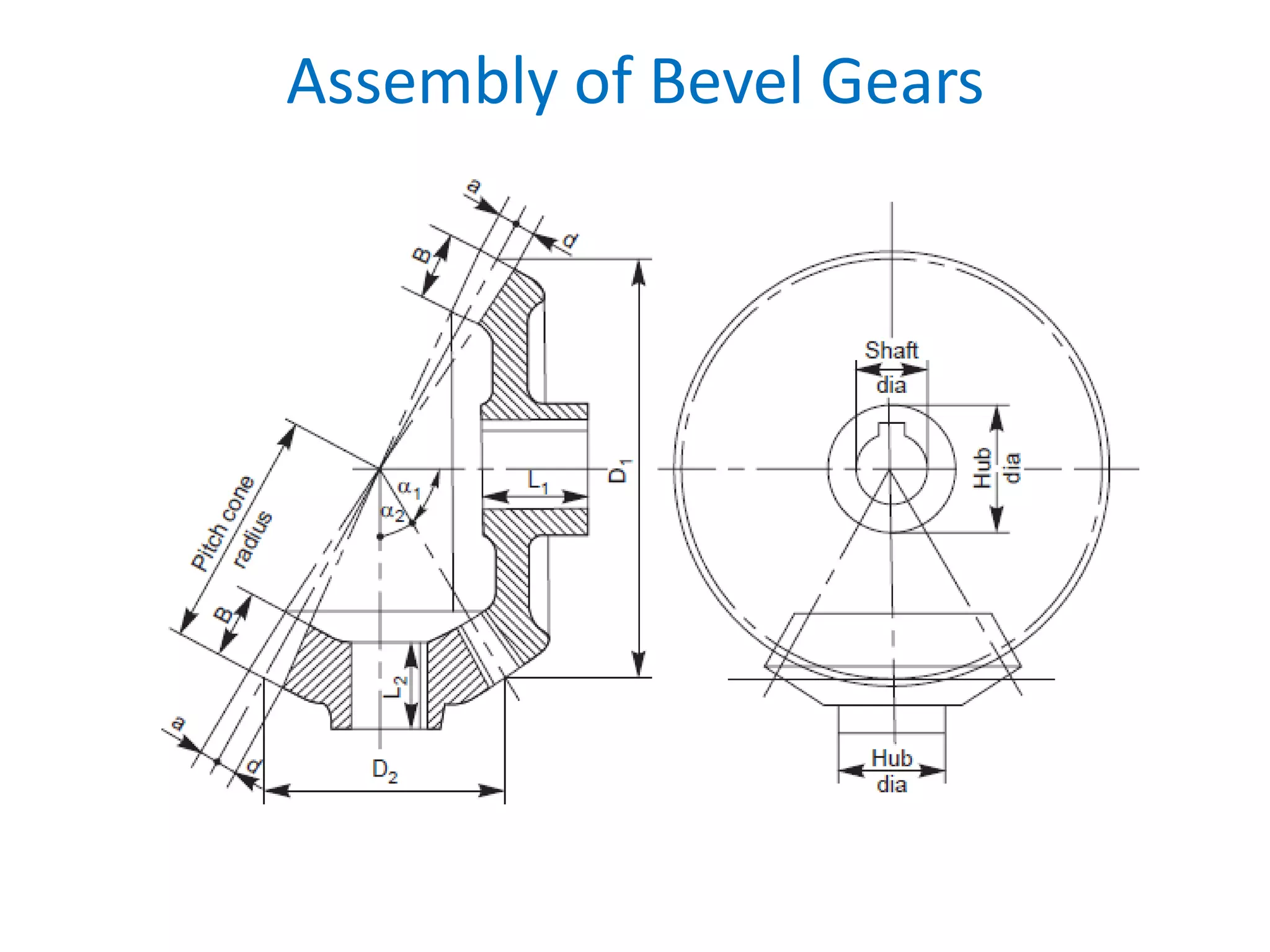

The document outlines a comprehensive machine drawing syllabus that covers various aspects of graphic language, classification of drawings, and standards for machine parts. It details orthographic projections, assembly drawings, dimensions, limits, fits, and tolerances, as well as gear terminology and calculations. It emphasizes the importance of standardized practices in engineering drawing to ensure clear communication among engineers globally.