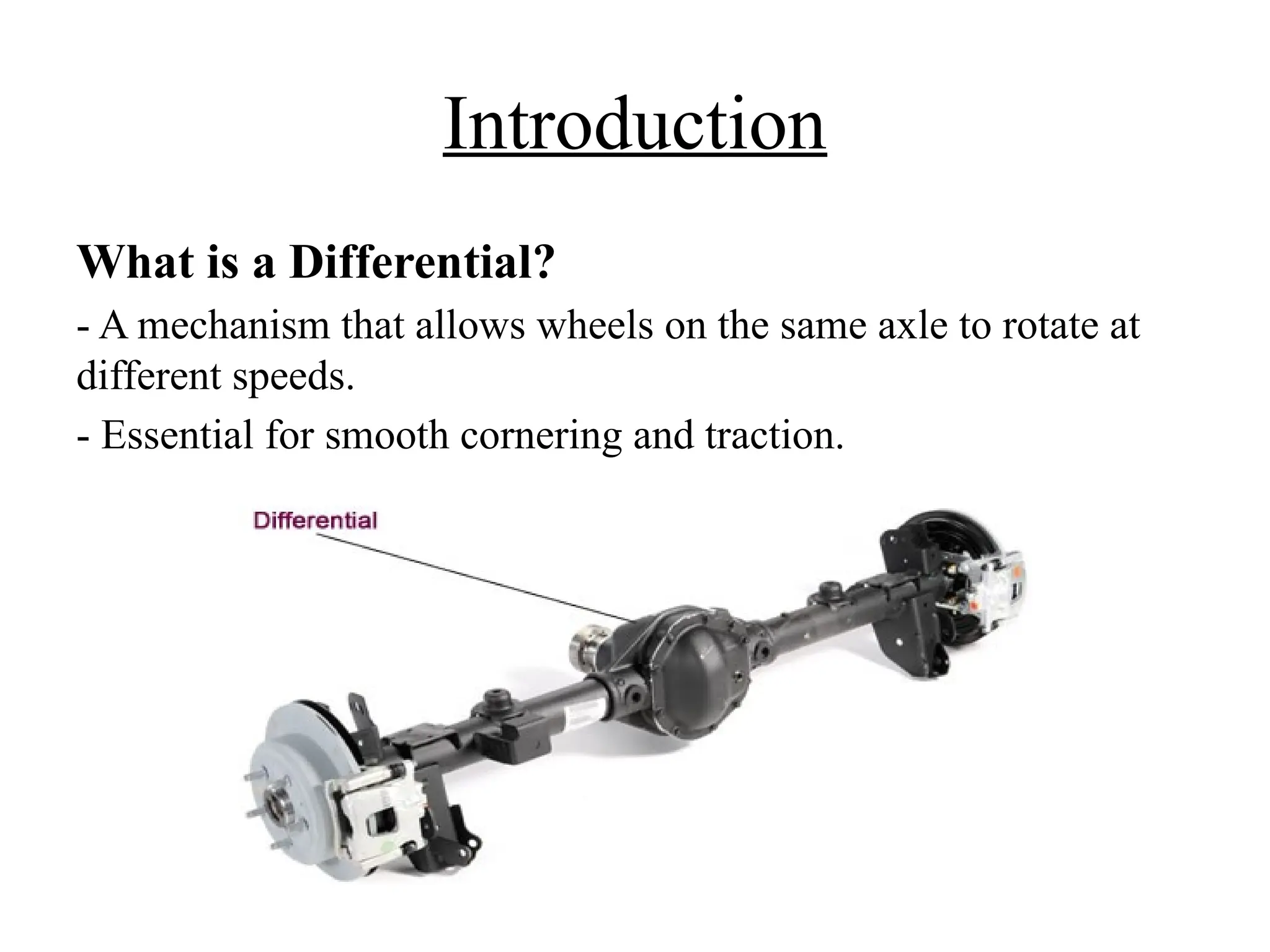

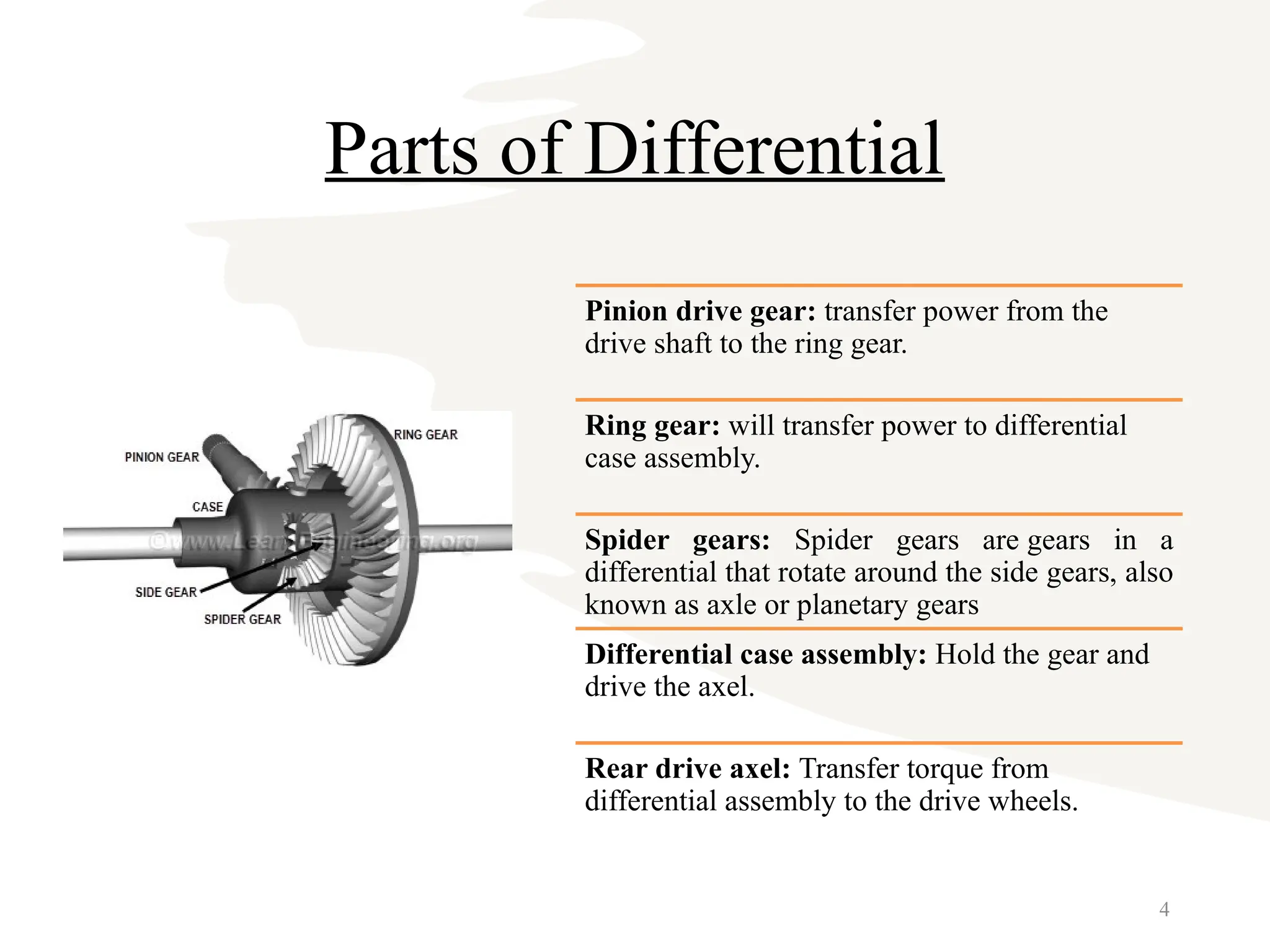

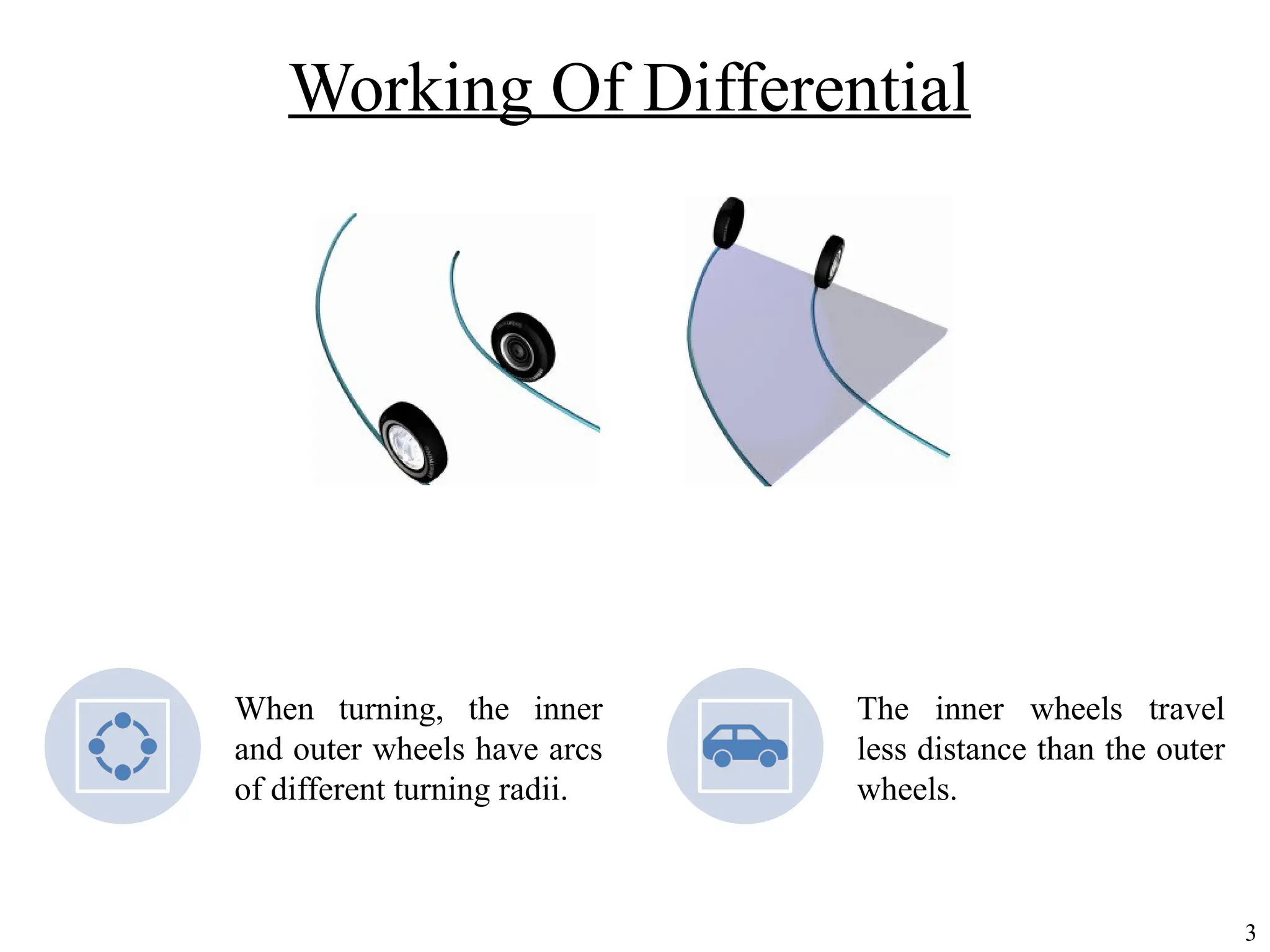

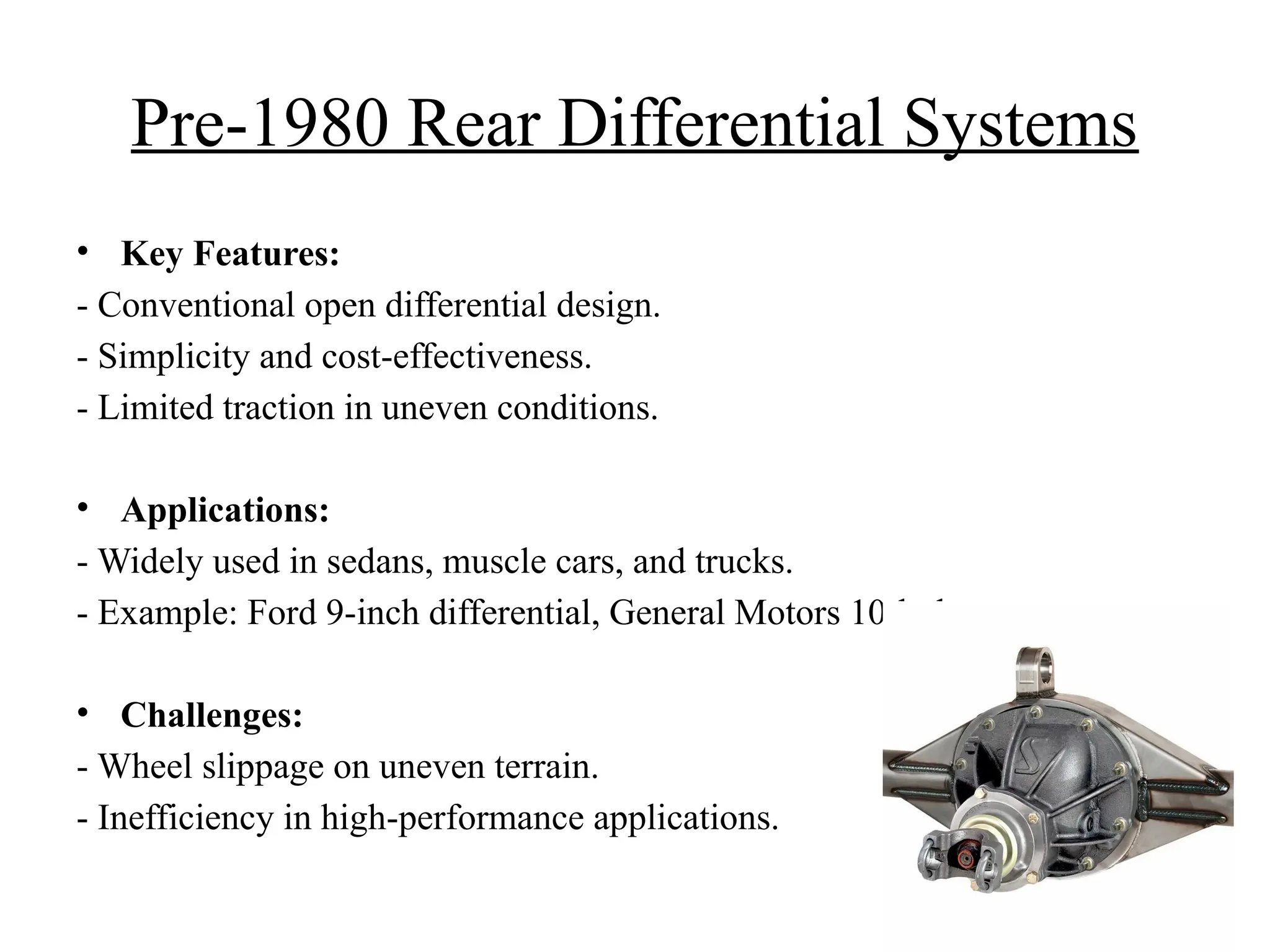

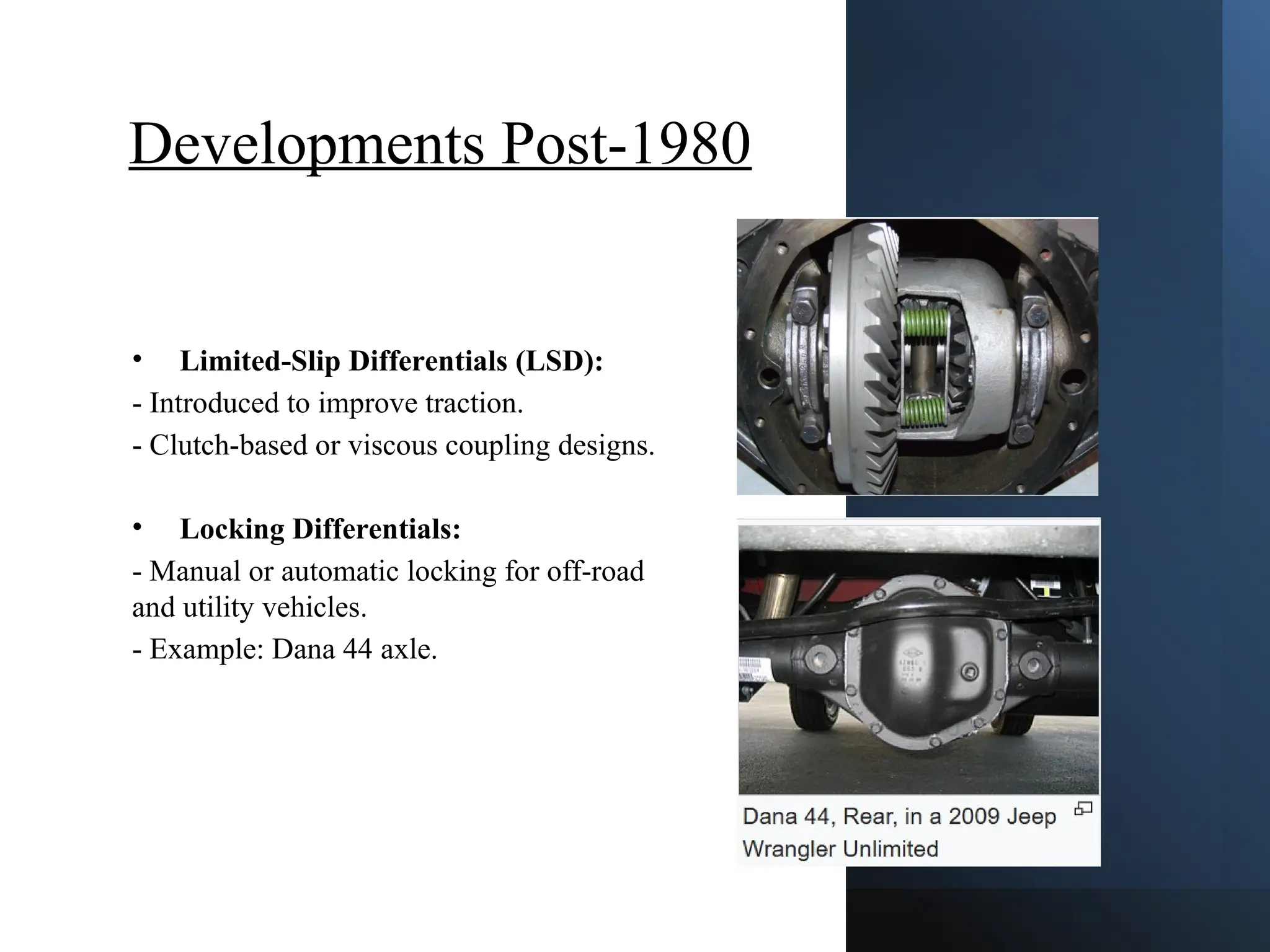

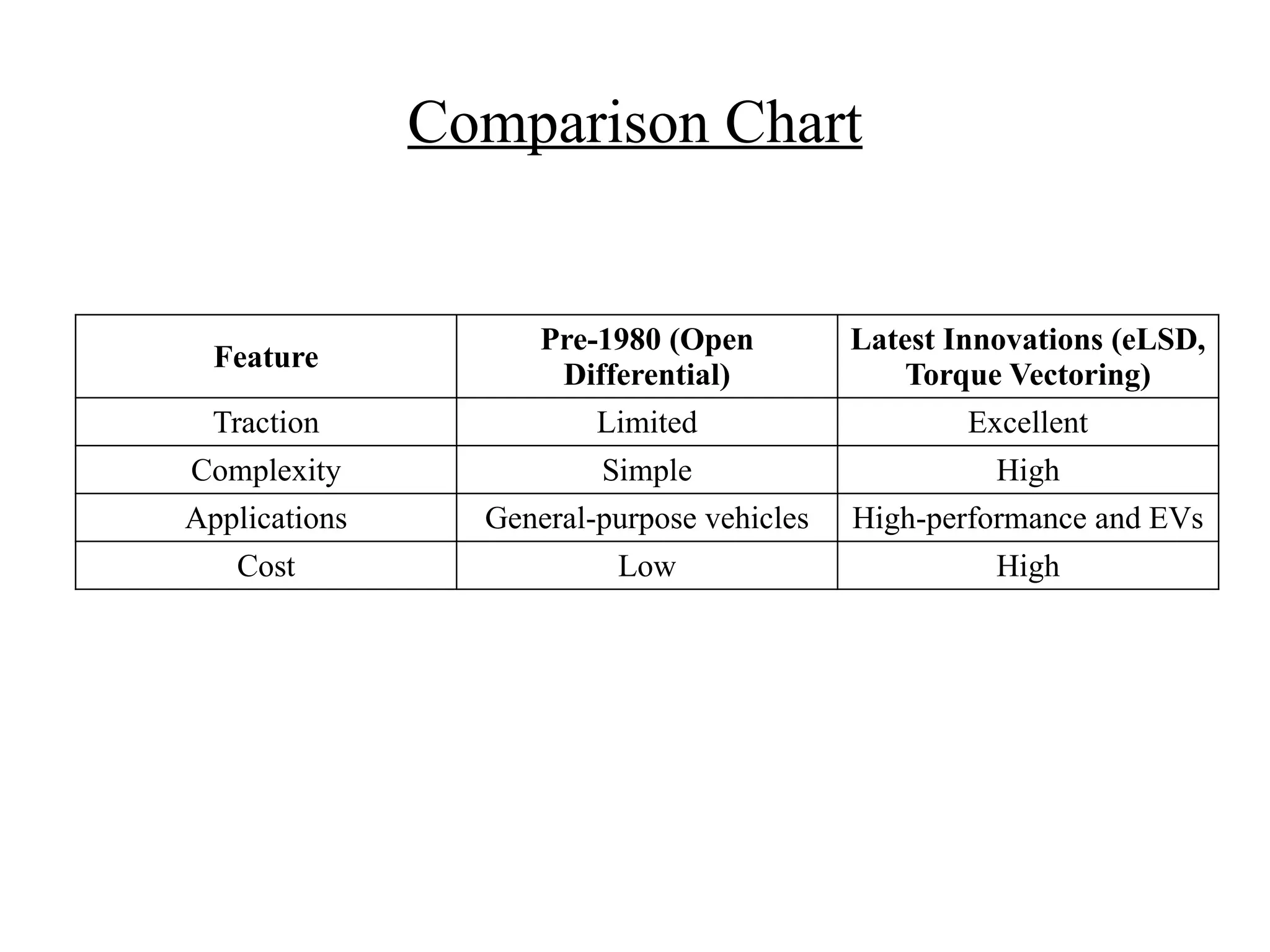

The document discusses the evolution of rear differential systems in vehicles, highlighting changes from pre-1980 conventional designs to modern innovations like electronic and torque vectoring differentials. Key advancements have focused on improving traction and performance, particularly in high-performance and electric vehicles. The future of differential systems includes further integration with autonomous technology and a push for enhanced efficiency.