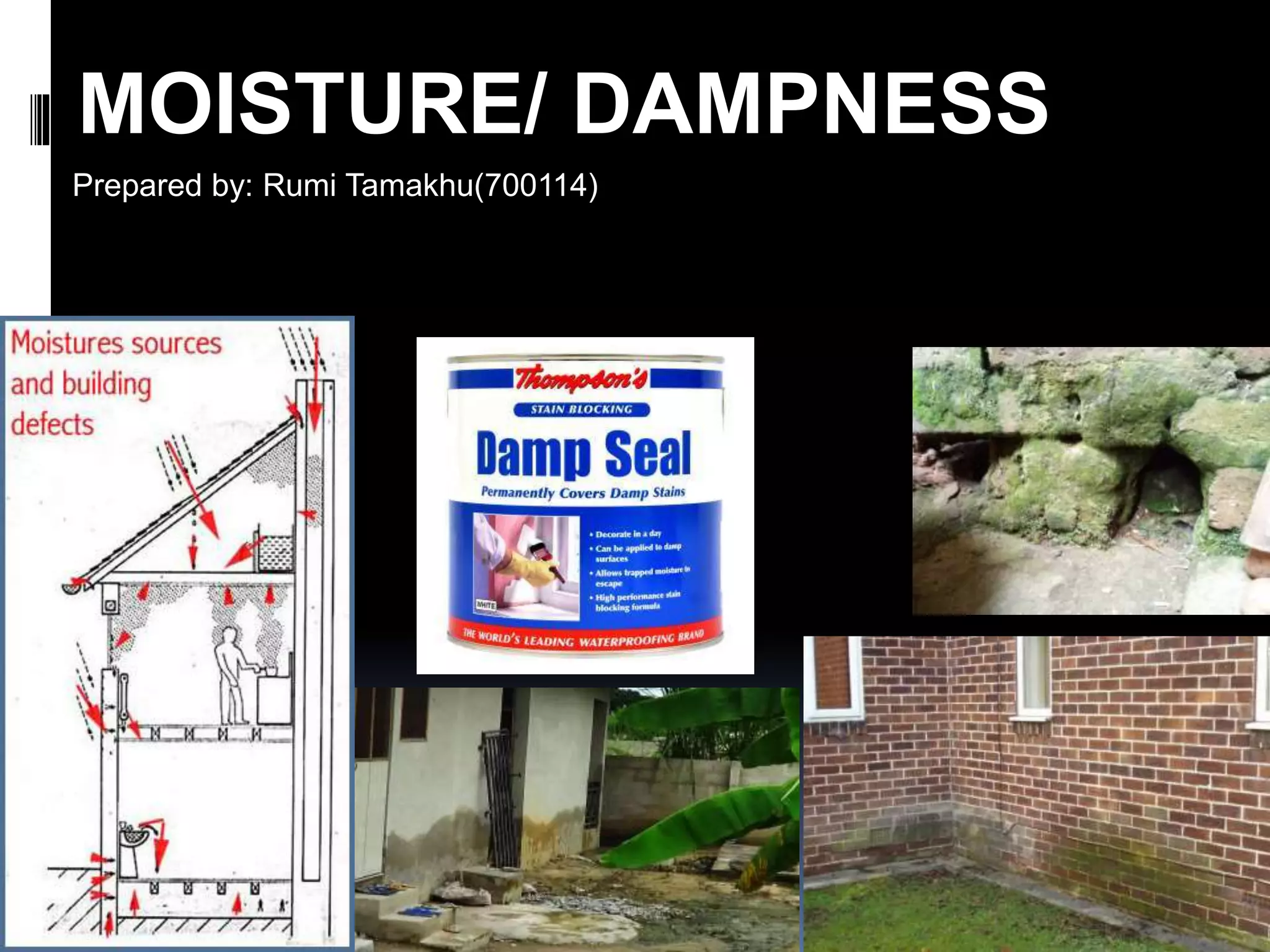

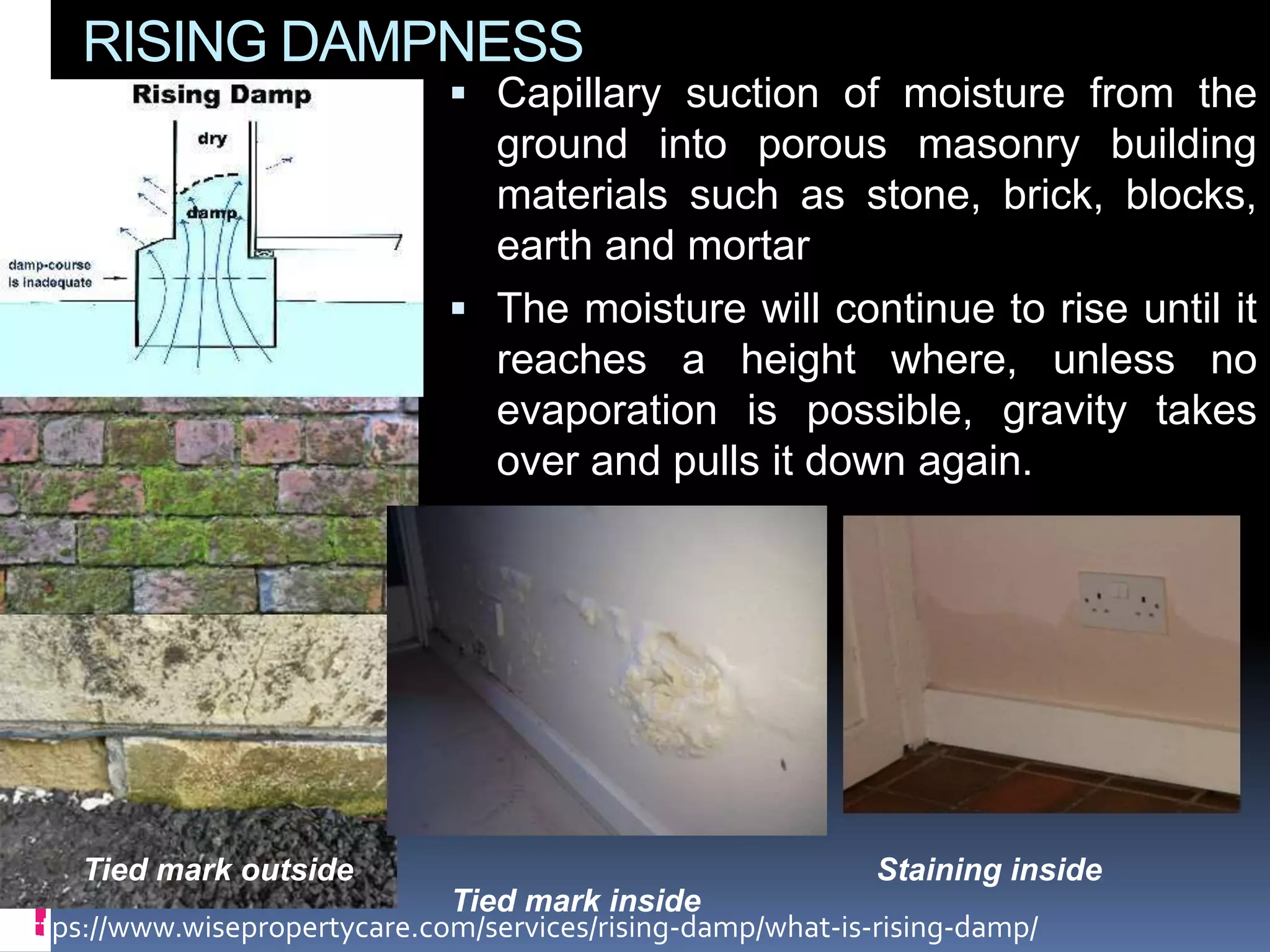

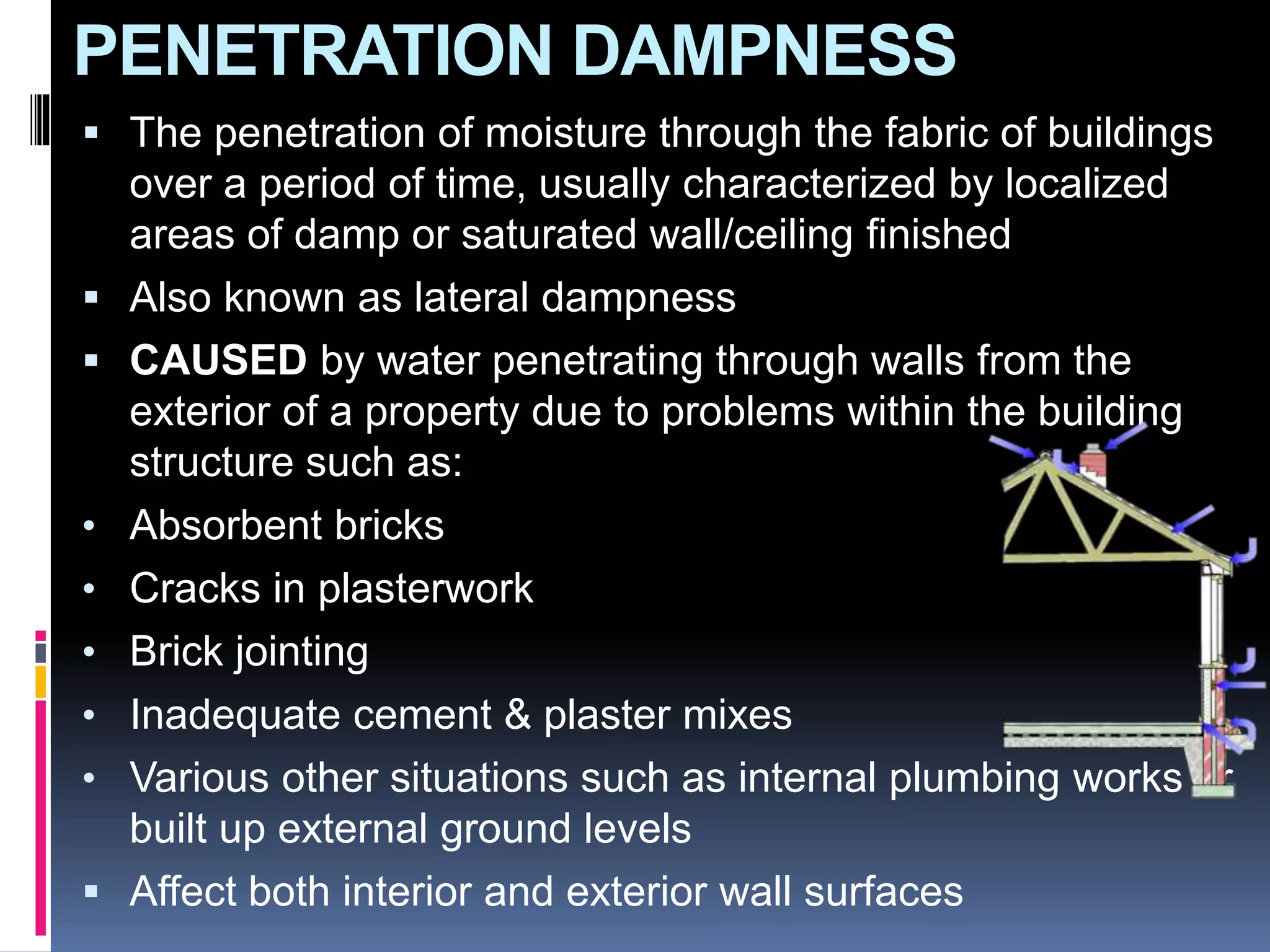

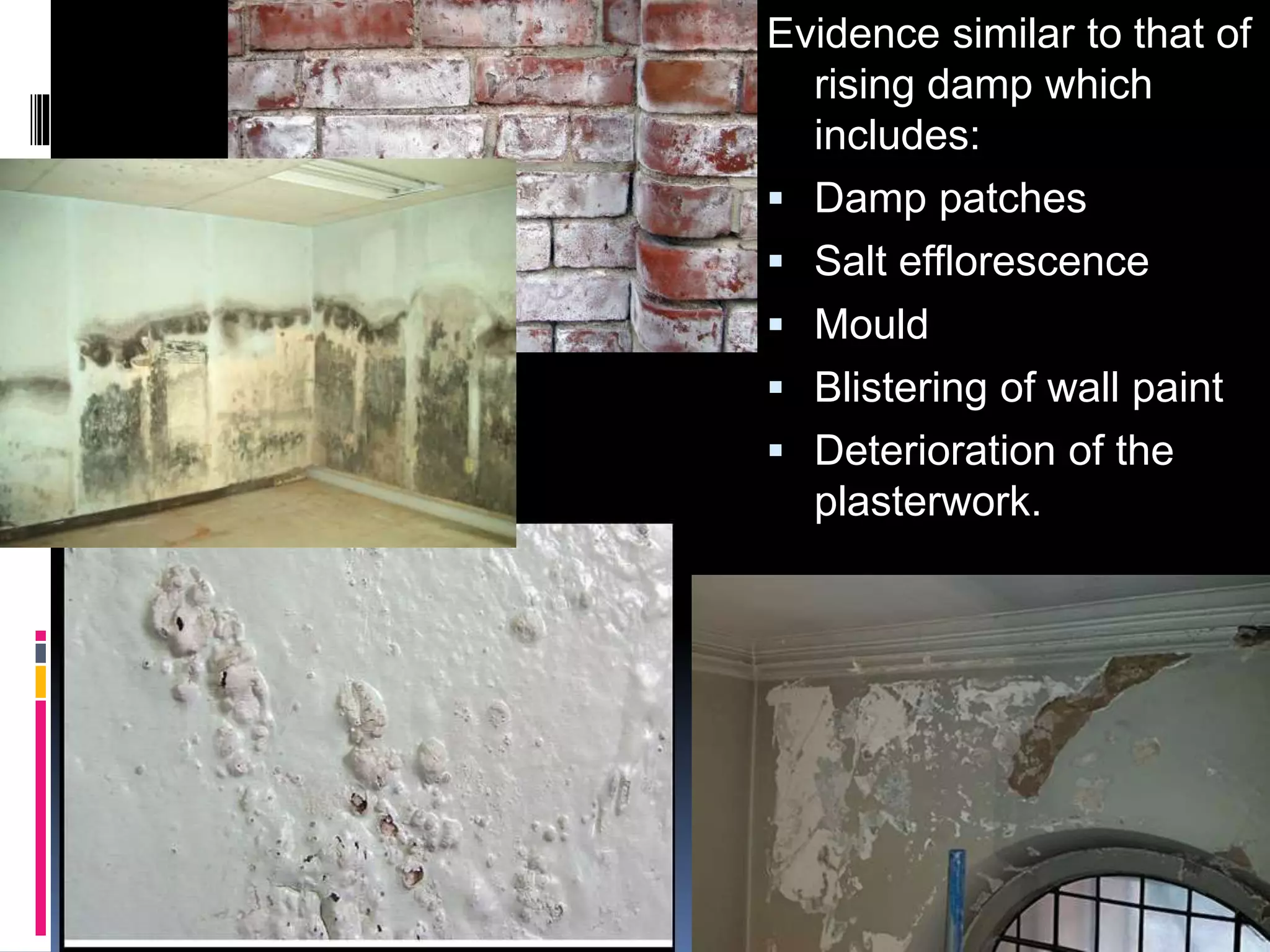

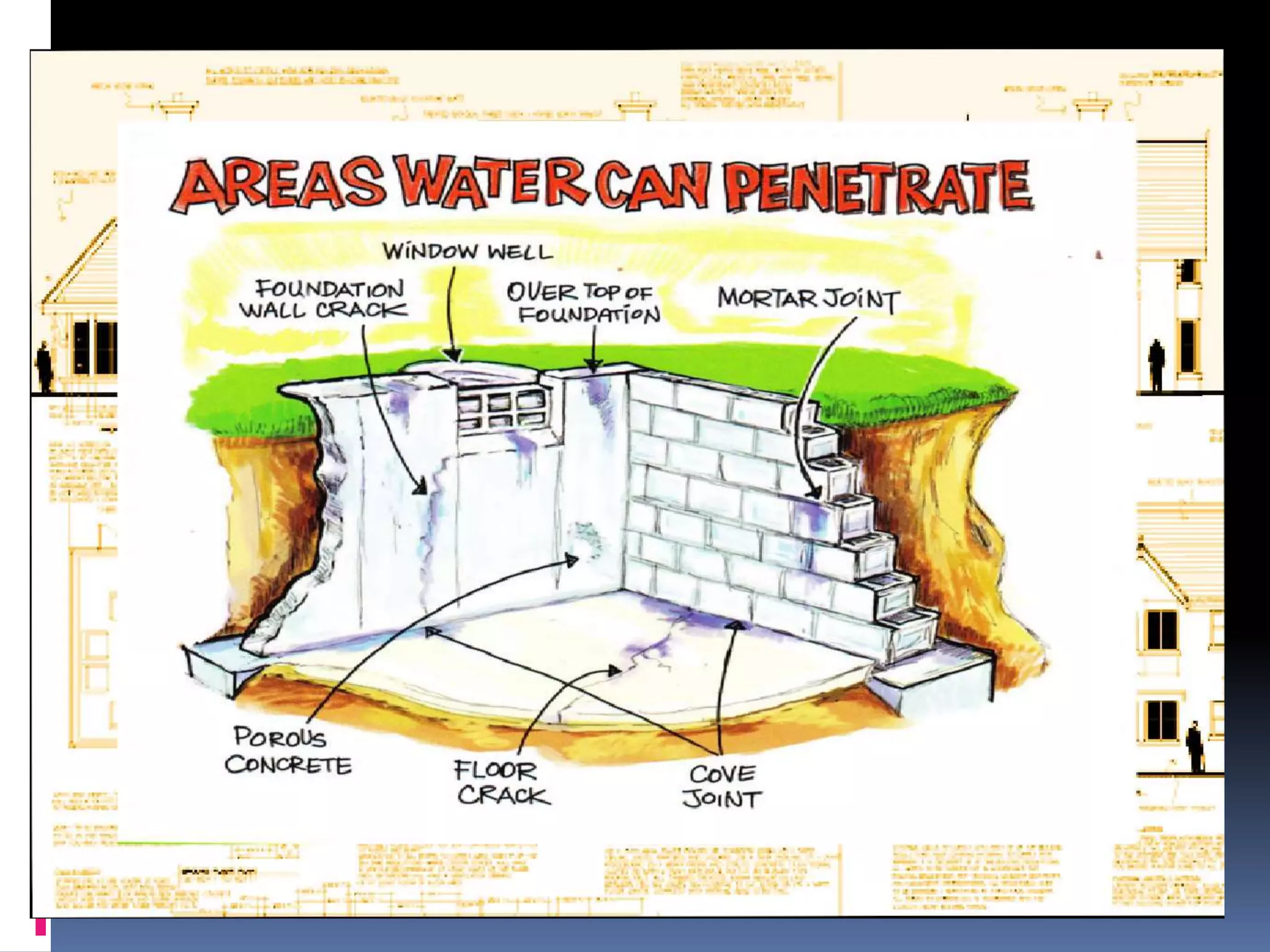

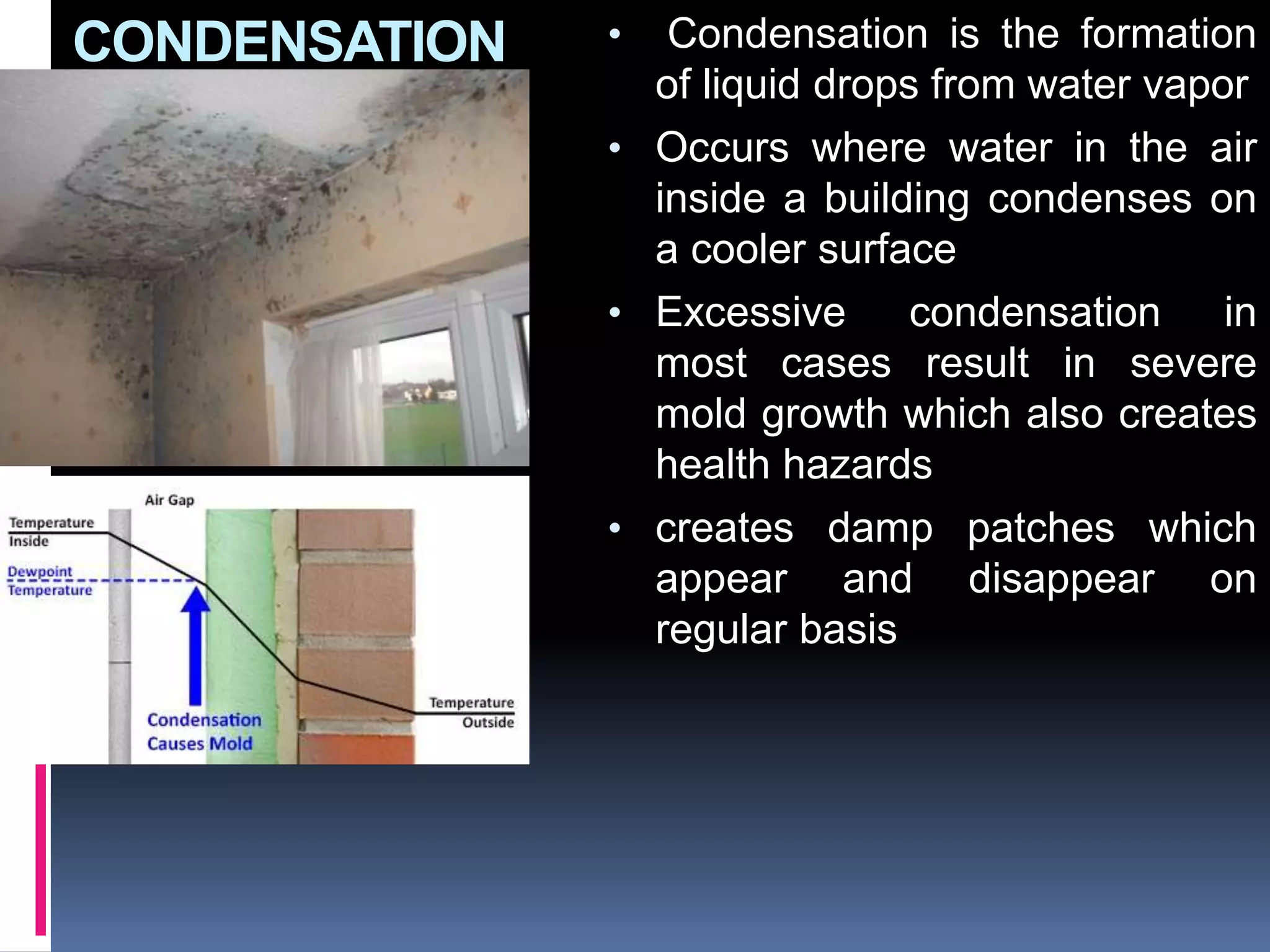

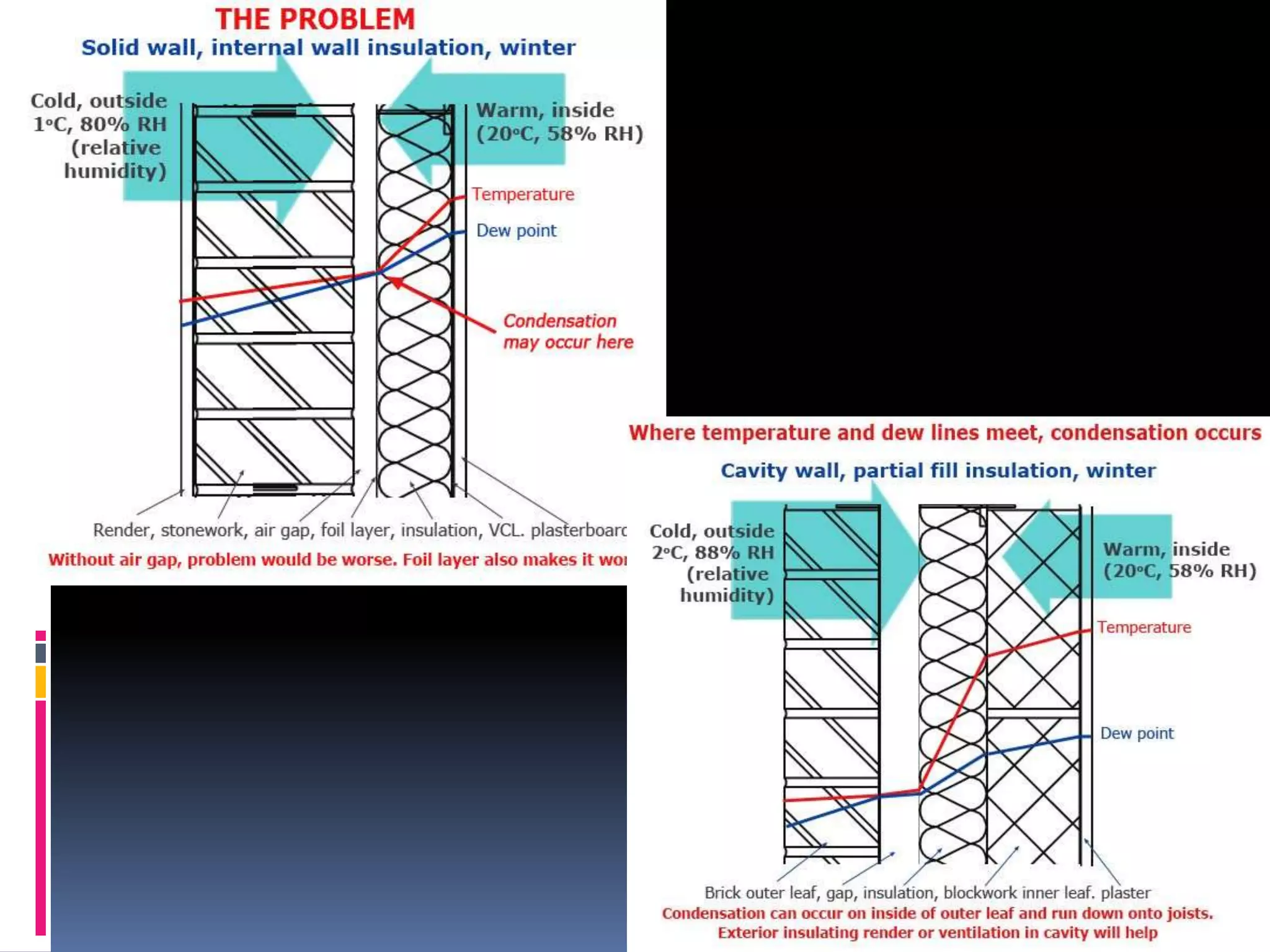

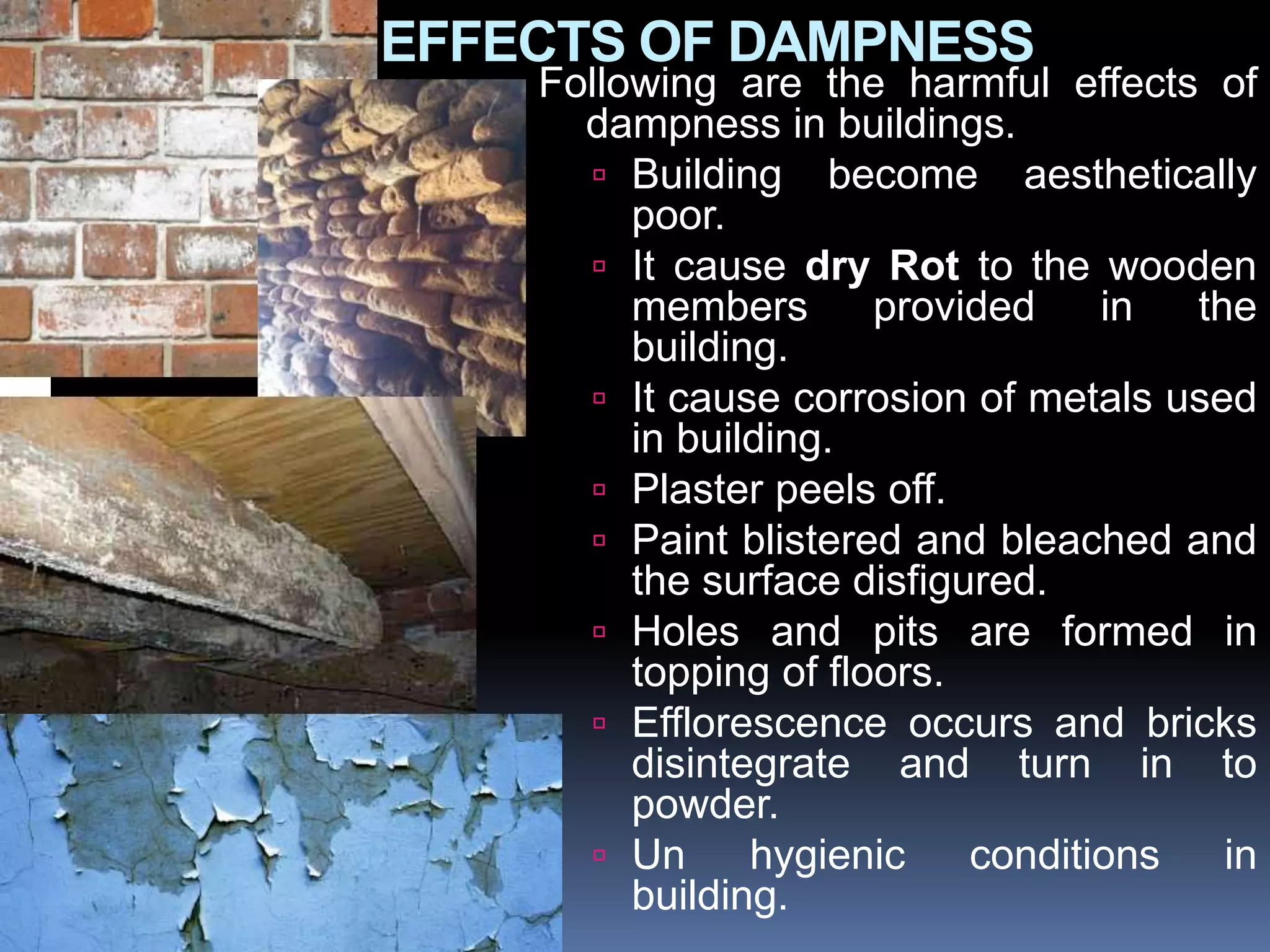

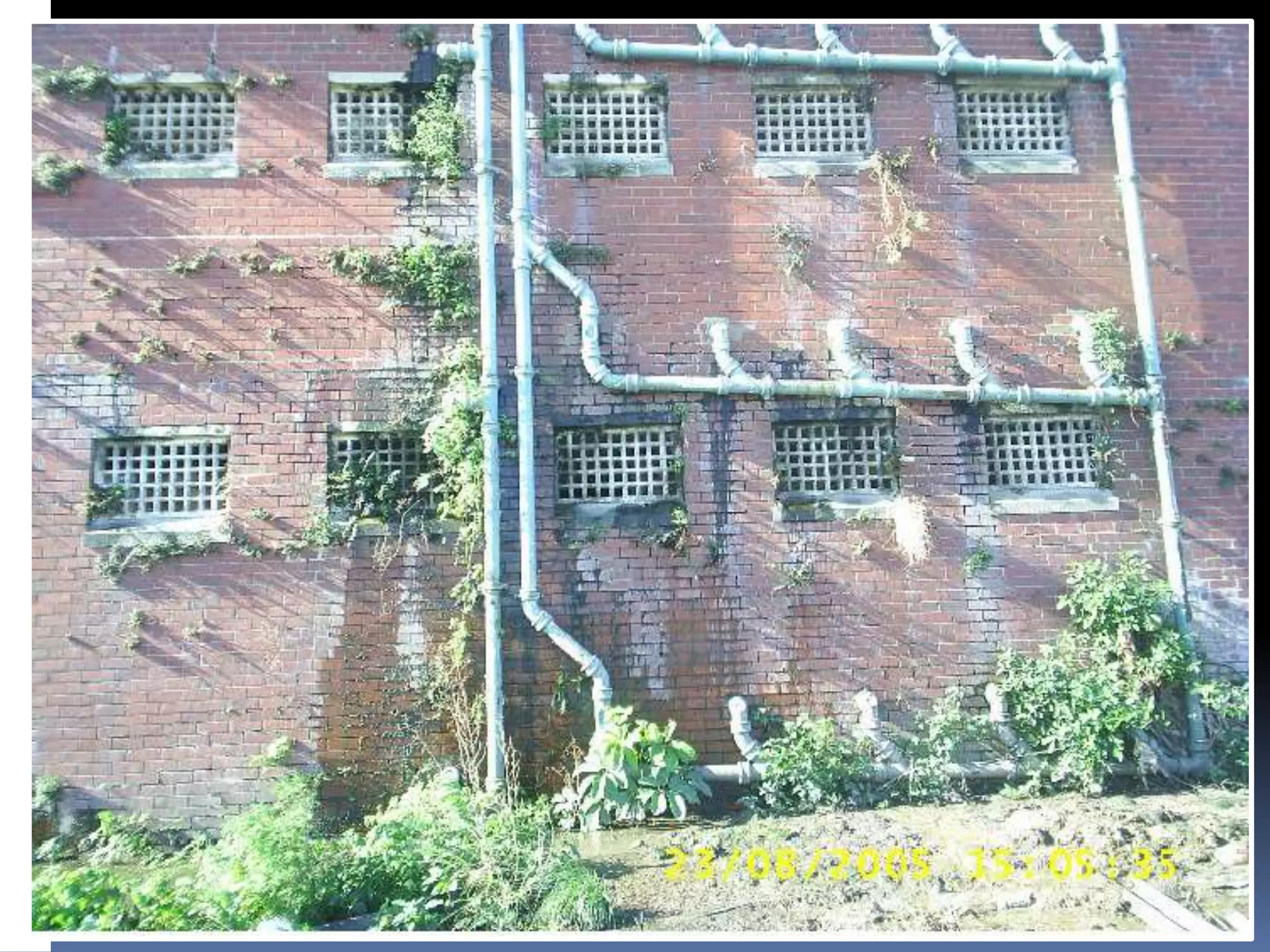

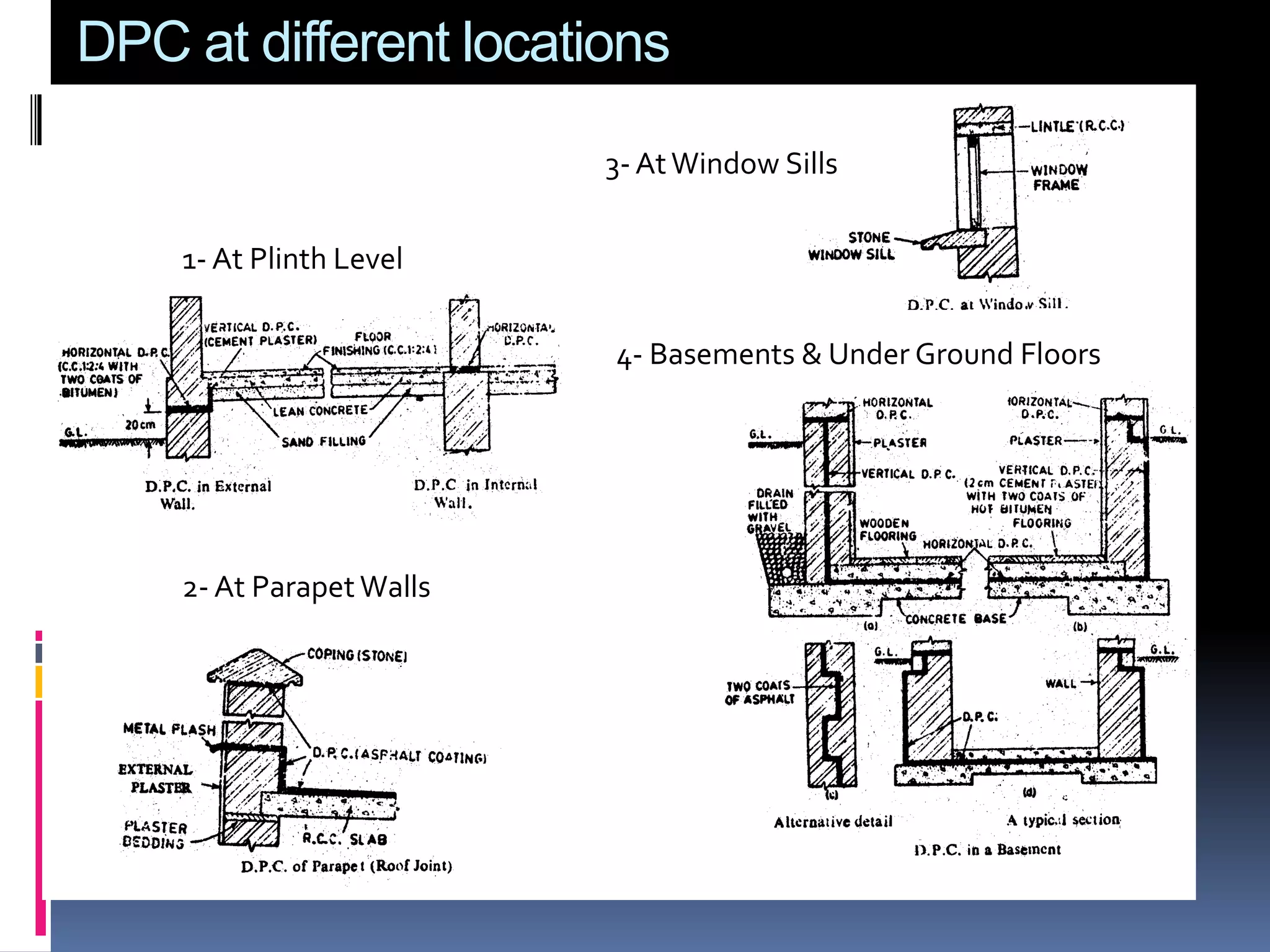

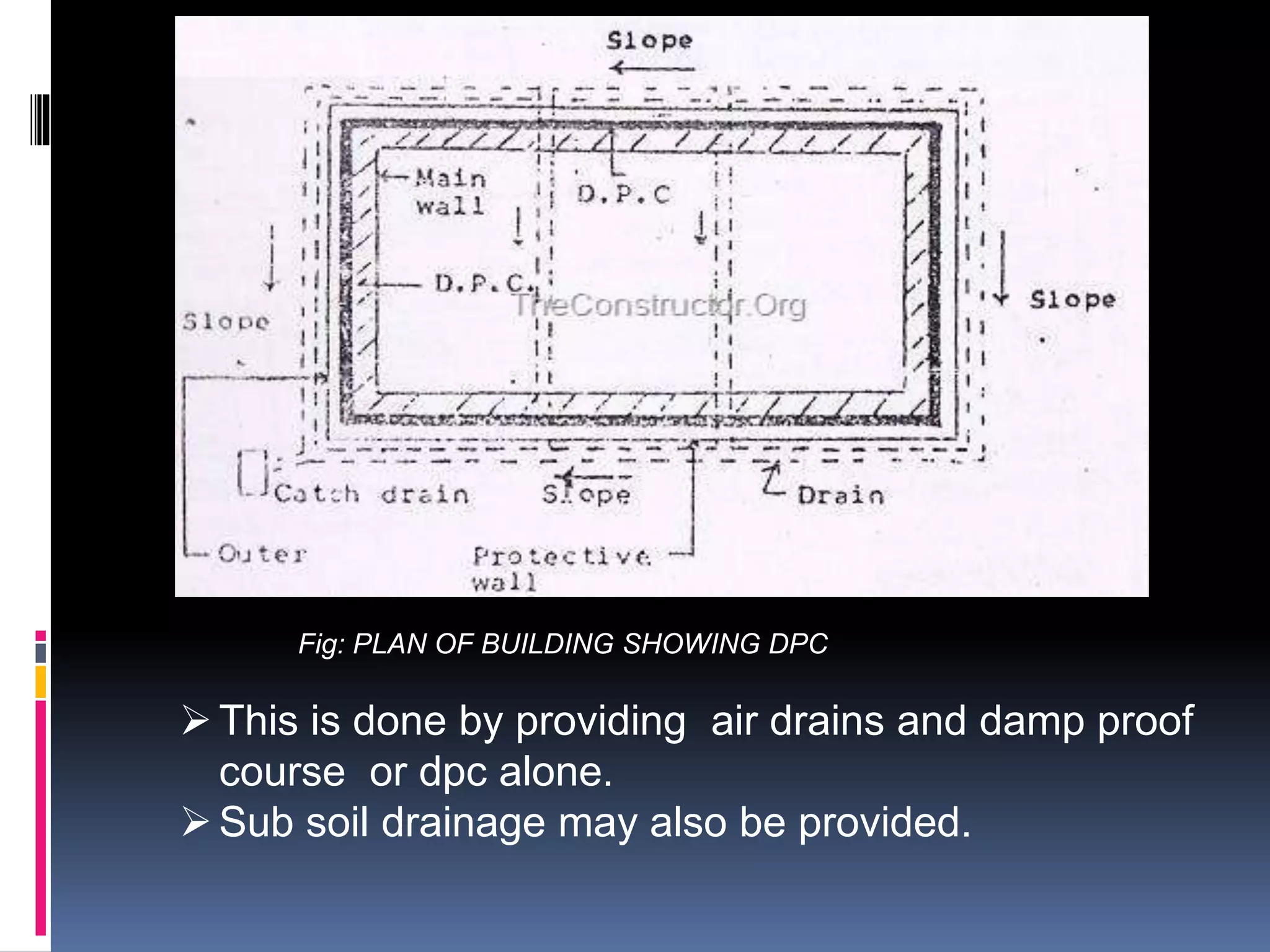

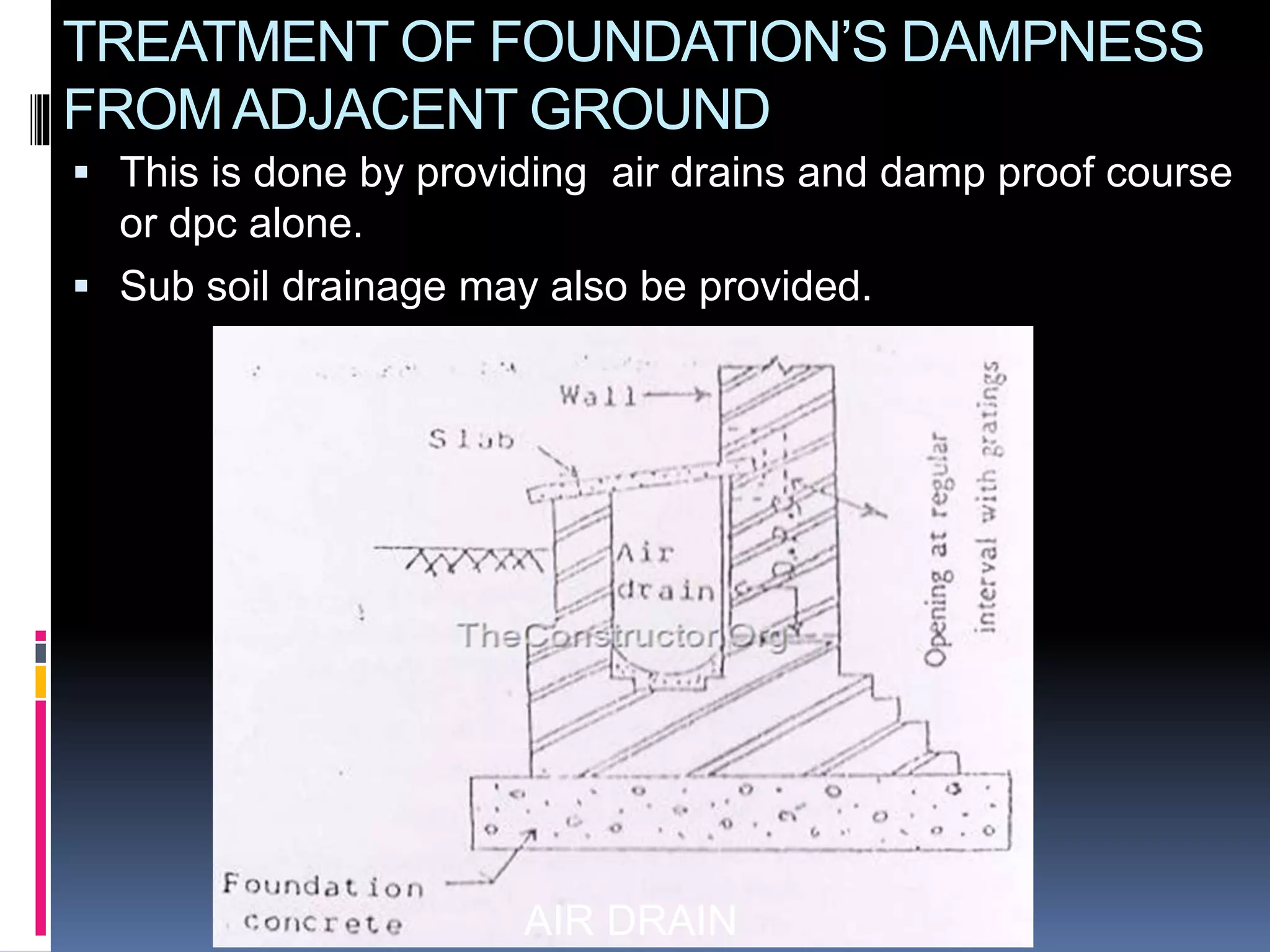

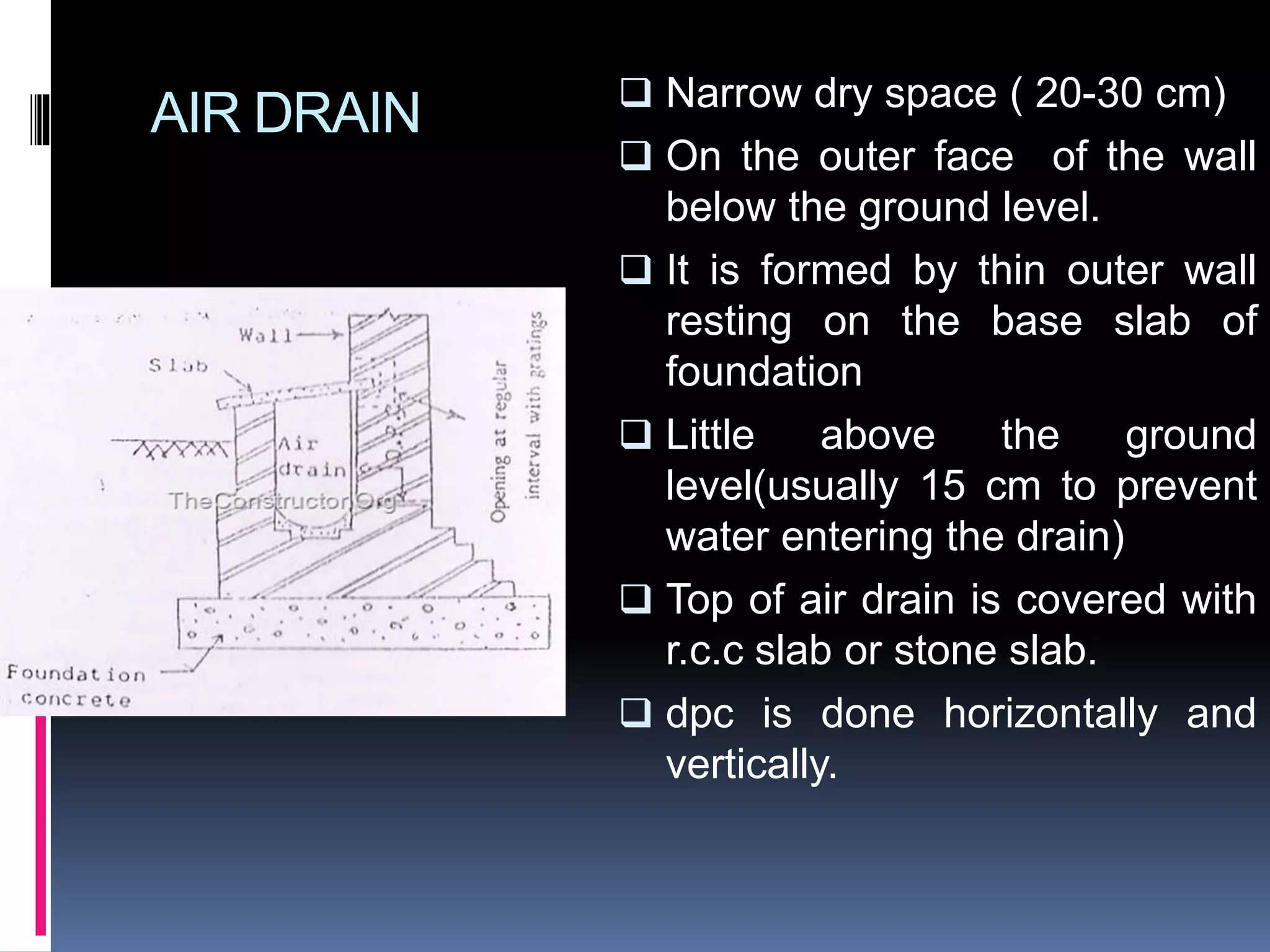

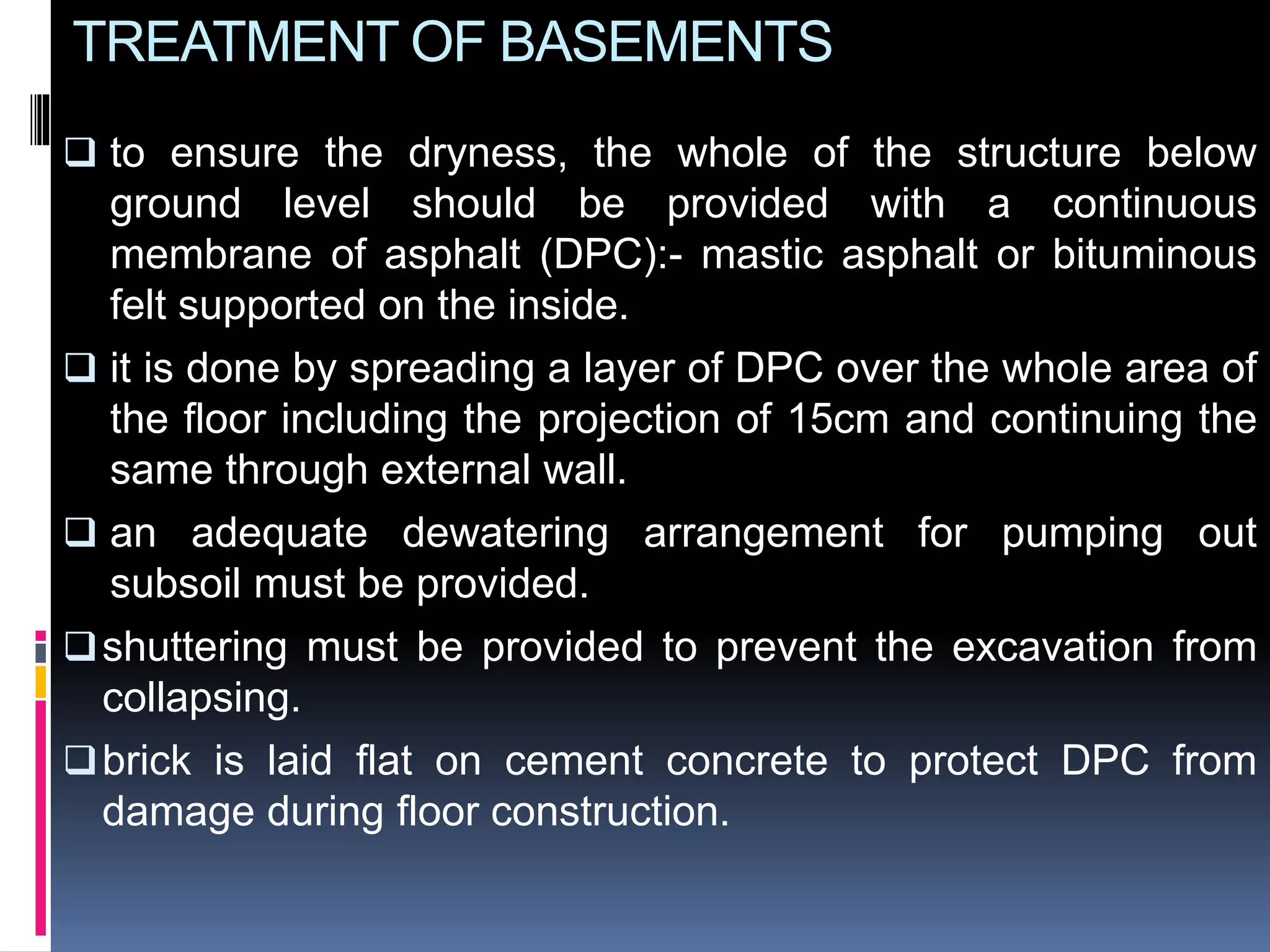

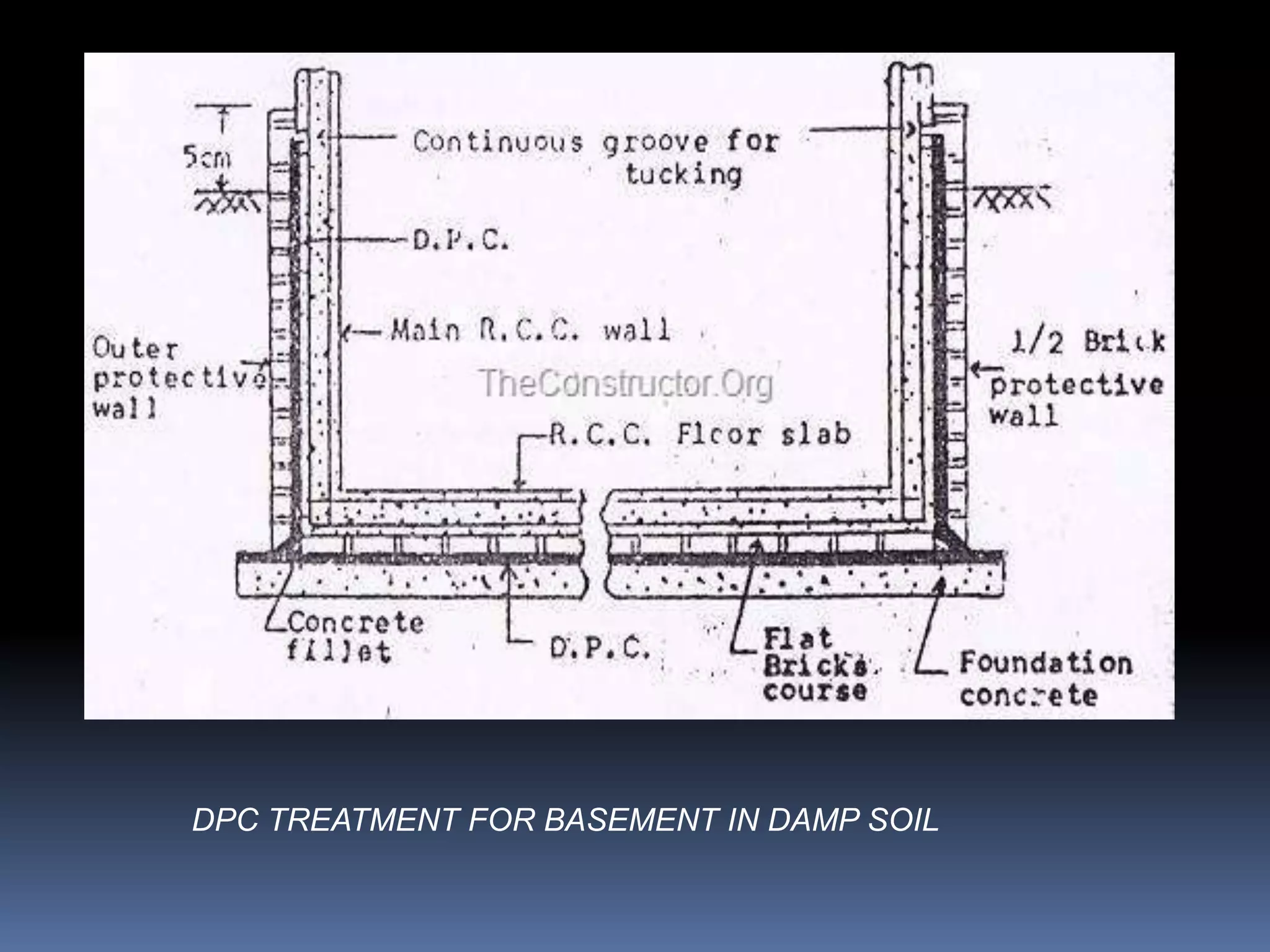

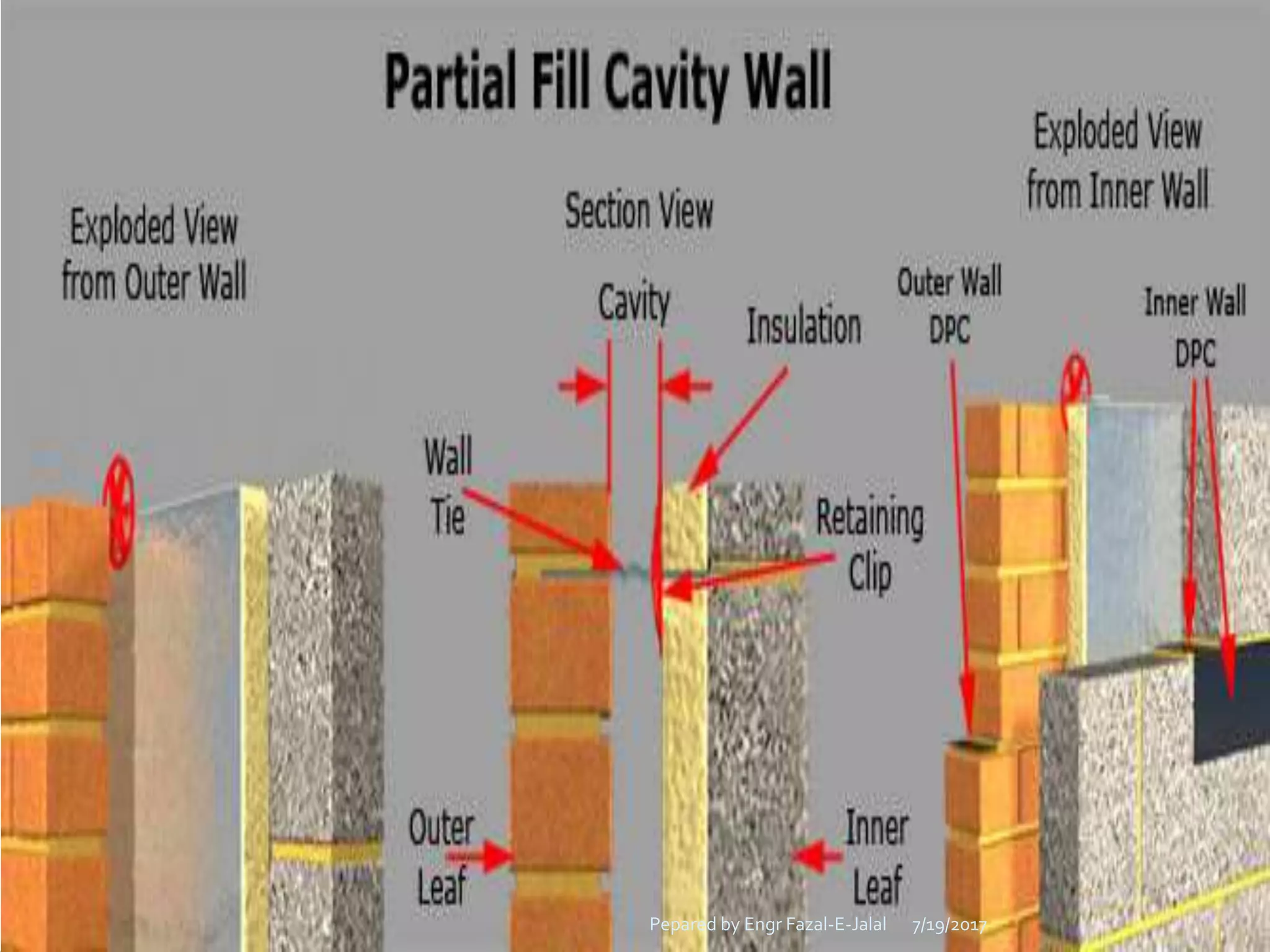

This document provides an overview of moisture and dampness in buildings. It defines dampness as excess moisture entering a building through floors, walls, or roofs. It identifies four main types of dampness based on moisture movement: rising damp, penetration damp, condensation damp, and outlines their causes. The effects of dampness include aesthetic issues, dry rot, corrosion, and health hazards. Remedial measures discussed include damp proof courses, waterproofing, and special techniques. Practical advice is given to reduce excessive moisture through proper ventilation and drainage, and timely repairs.