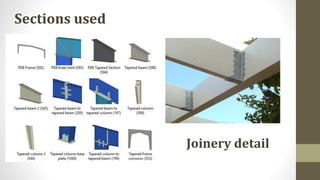

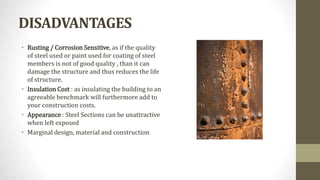

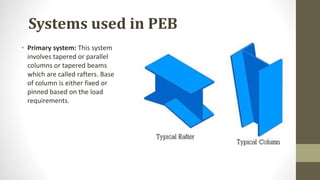

Pre-engineered buildings are factory-built steel structures that are shipped to sites in pieces and bolted together for quick assembly. They are rectangular structures enclosed in corrugated metal sheeting. PEB construction is fast because foundations are poured while factory fabrication occurs. PEBs have primary and secondary structural elements, roof/wall panels, and accessories. They provide benefits like reduced construction time, lower costs, flexibility for expansion, large clear spans, quality control, and energy efficiency. However, they also have disadvantages like corrosion sensitivity, added insulation costs, and limited design customization. PEBs are commonly used for warehouses, factories, workshops, and other industrial and commercial buildings.