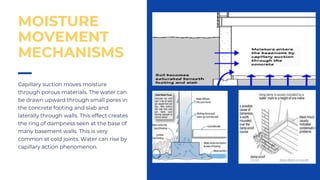

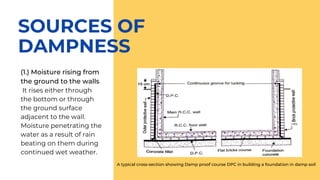

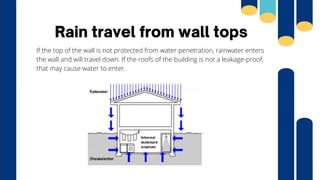

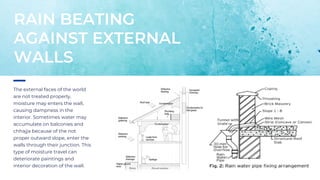

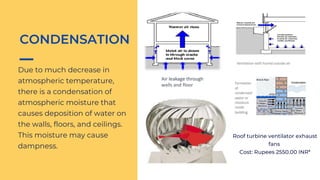

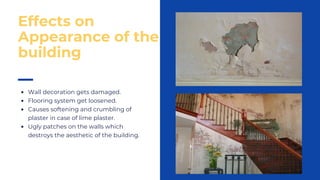

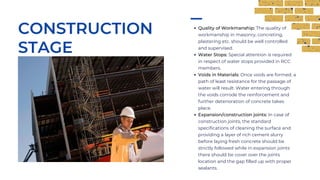

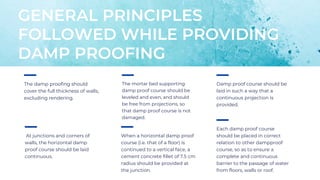

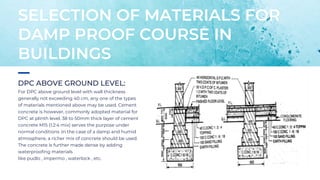

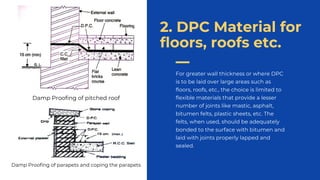

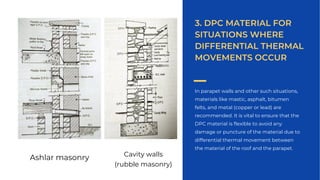

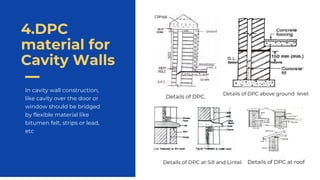

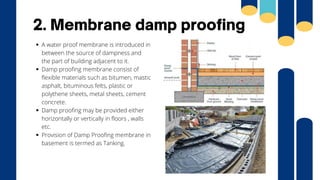

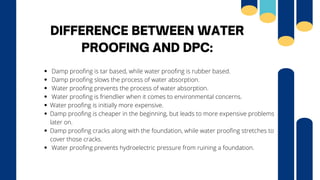

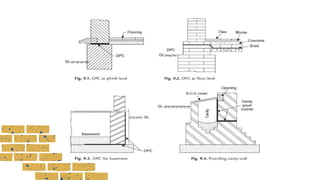

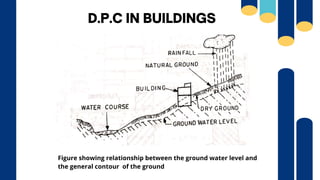

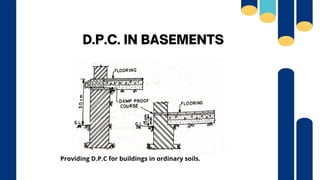

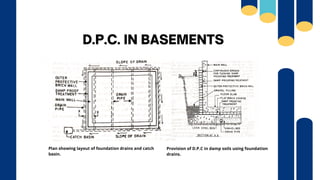

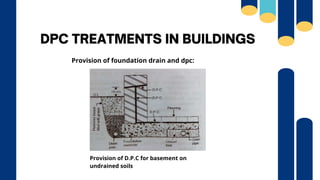

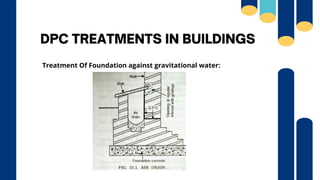

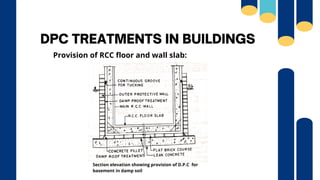

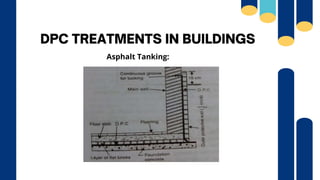

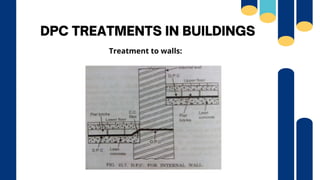

The document discusses dampness in buildings, identifying its sources and the introduction of a damp proof course (DPC) as a barrier against moisture penetration. It explains the causes and effects of dampness, its impact on health and structural integrity, and outlines methods for prevention and treatment including various materials for damp proofing. Additionally, it differentiates between damp proofing and waterproofing, detailing the benefits and applications of each.