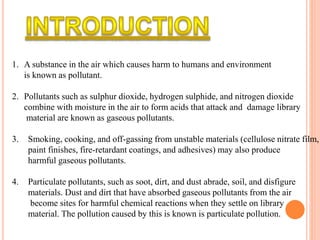

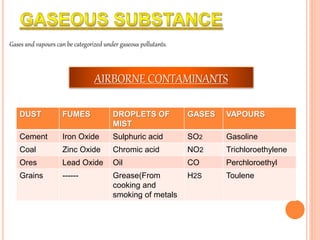

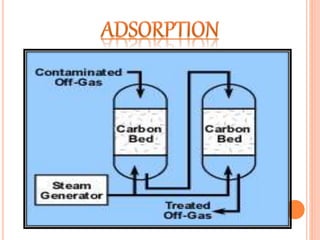

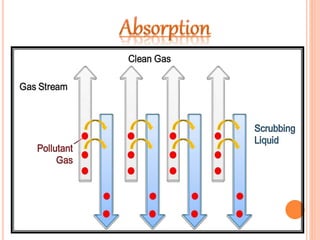

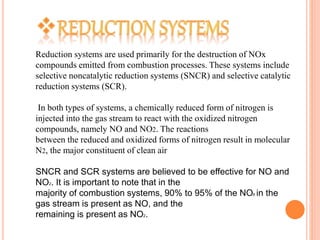

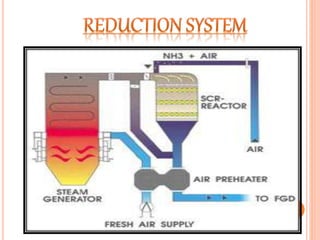

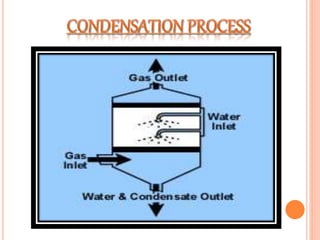

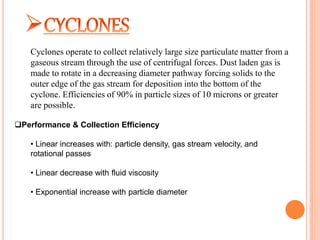

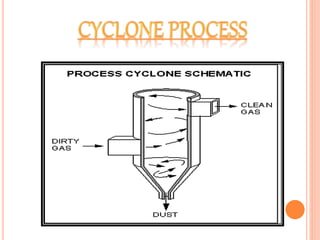

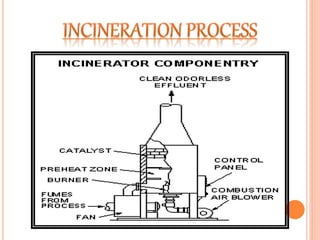

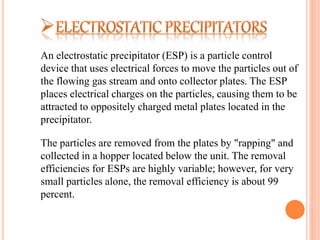

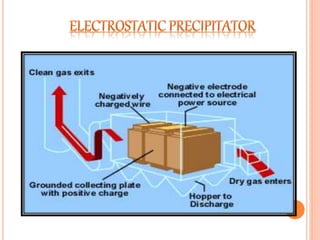

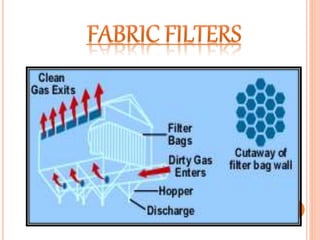

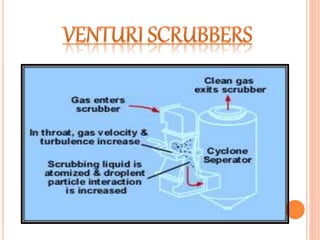

The document discusses various methods and devices for controlling gaseous and particulate pollutants, highlighting their impact on health and the environment. It covers specific pollutants, their sources, and control technologies, including adsorption, absorption, biological treatment, and various filtration and collection systems. The text emphasizes the importance of prevention and identifying pollution sources to effectively manage air quality.