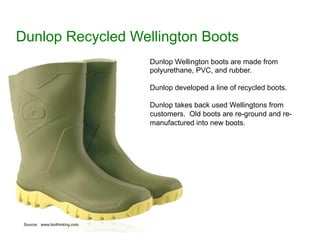

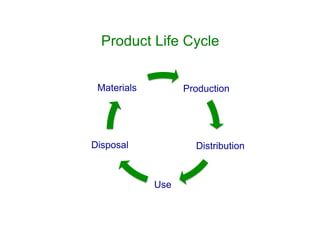

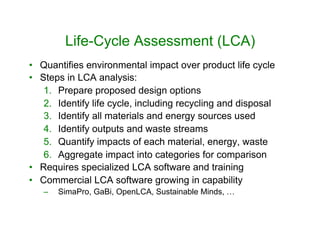

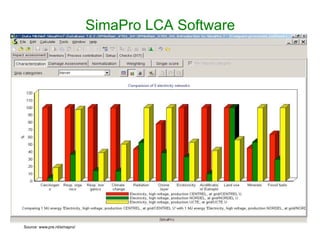

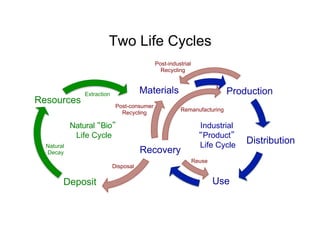

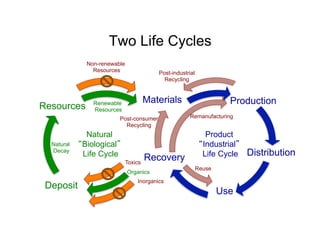

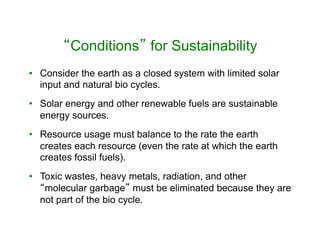

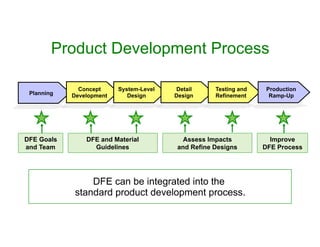

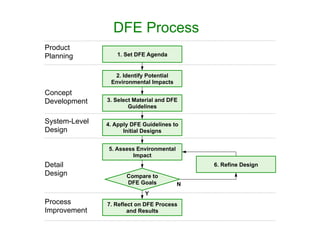

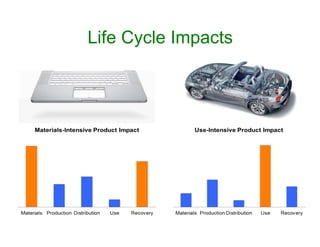

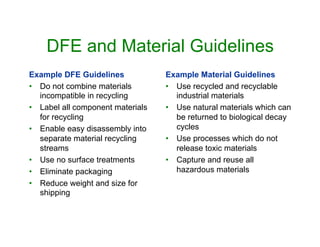

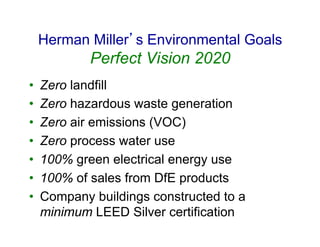

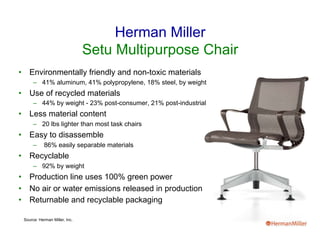

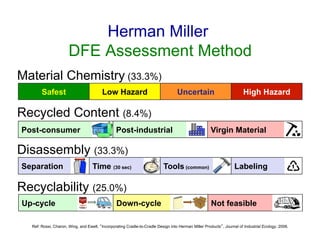

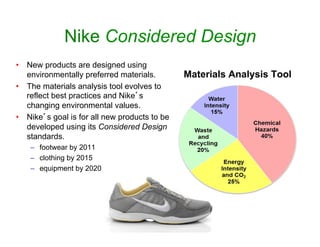

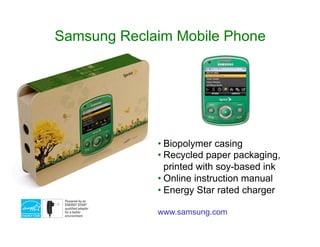

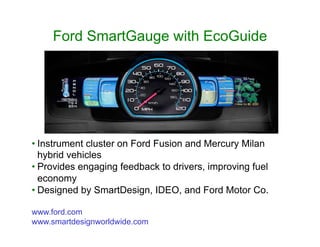

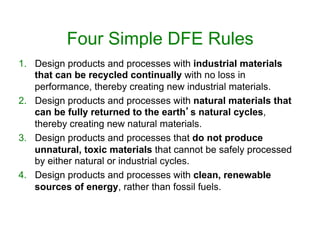

This document provides an overview of key concepts from Chapter 12 on Design for Environment from the textbook Product Design and Development by Karl T. Ulrich and Steven D. Eppinger. It discusses how design for environment (DFE) aims to minimize a product's environmental impact over its lifecycle. DFE expands the traditional focus on production to consider the entire closed-loop lifecycle. Methods like life-cycle assessment and cradle-to-cradle design are introduced. Examples of companies implementing DFE through use of recycled materials, design for disassembly, and other strategies are also provided.