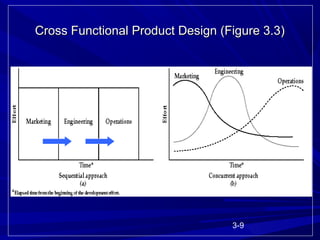

This document discusses product design processes and tools. It covers strategies for new product introduction, the new product development process, and the importance of cross-functional design. Key design tools discussed include Quality Function Deployment for capturing customer needs, Design for Manufacturing to enable producibility, Value Analysis for cost optimization, and Modular Design to increase commonality across product lines.