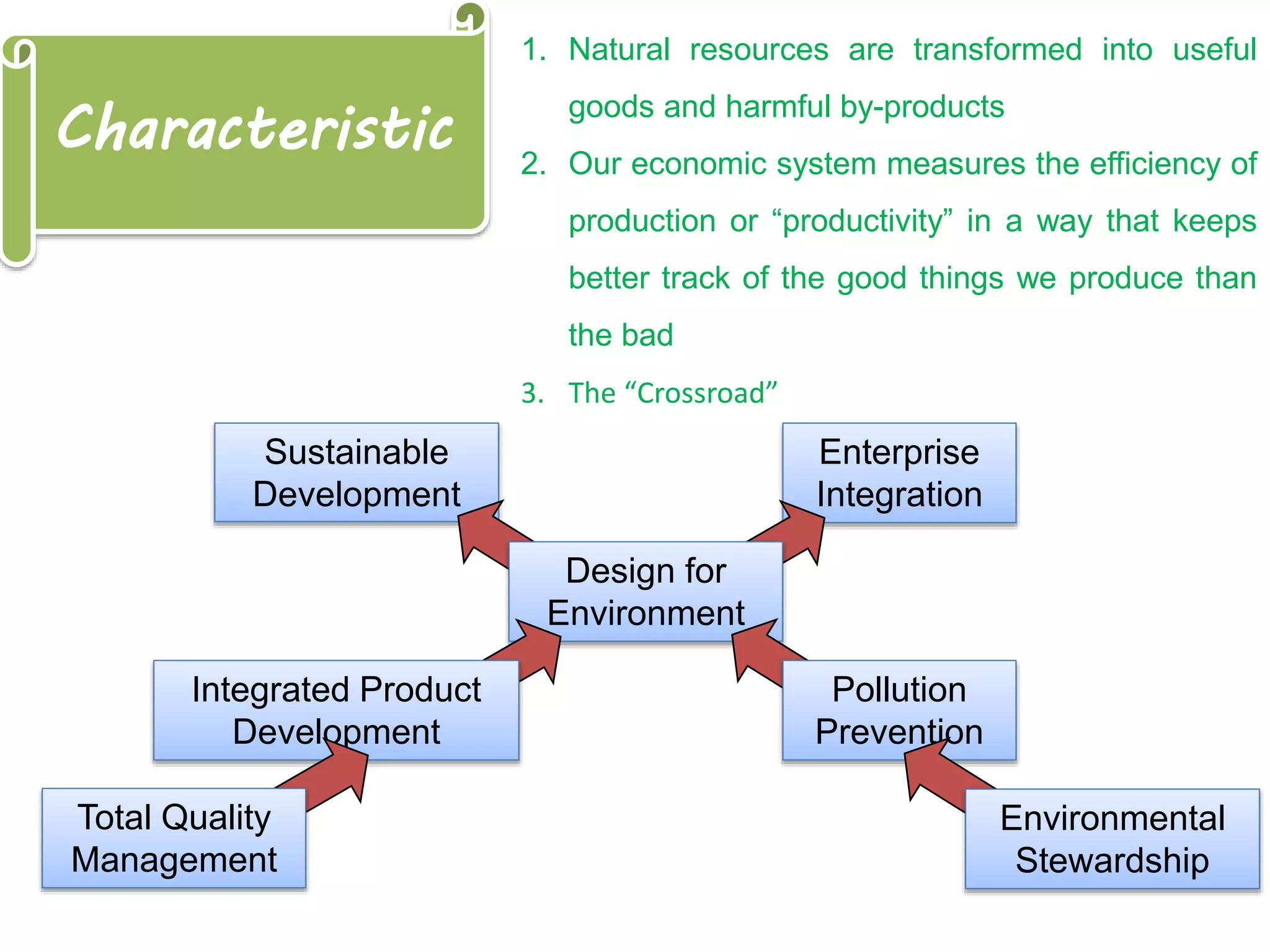

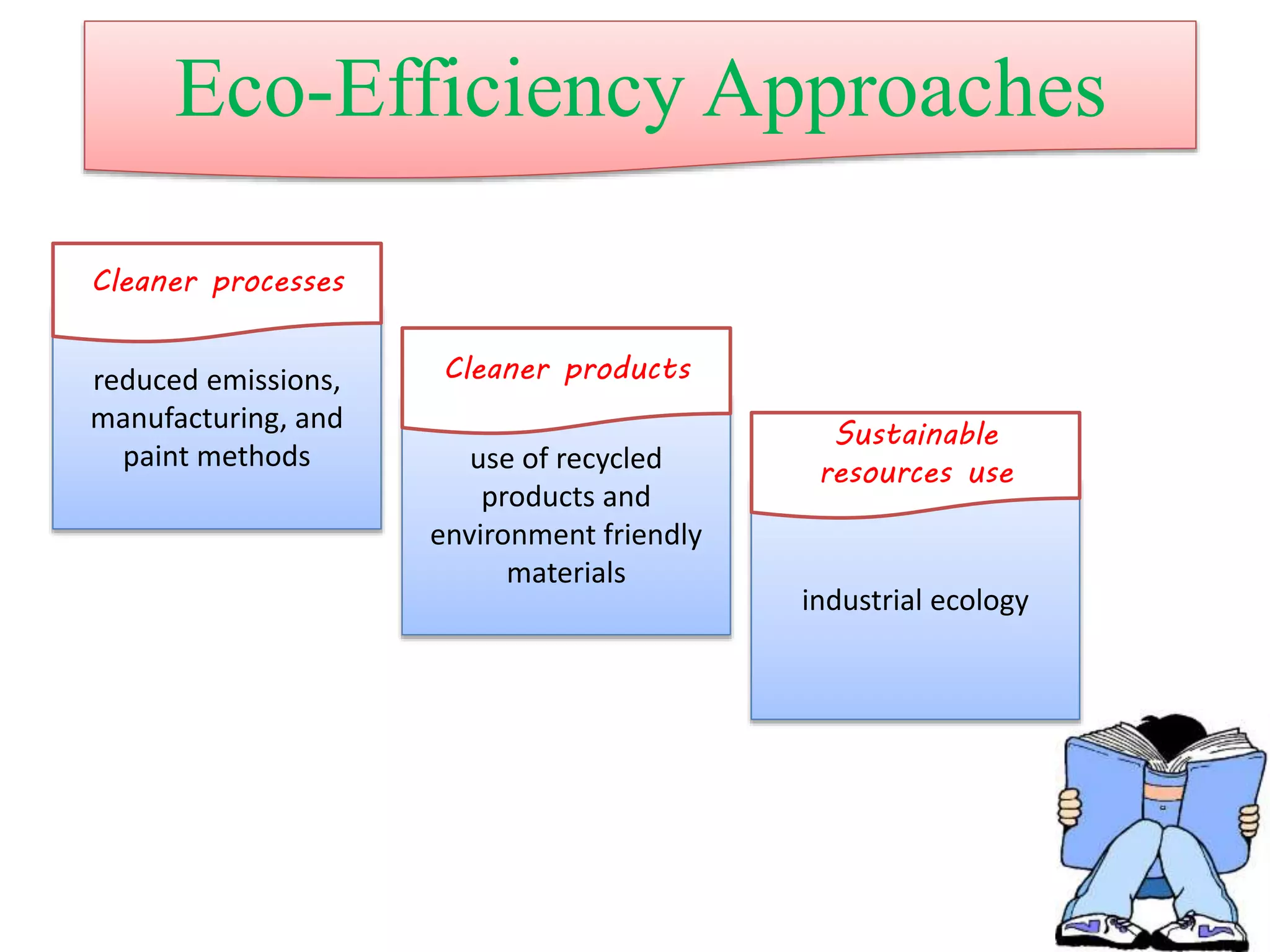

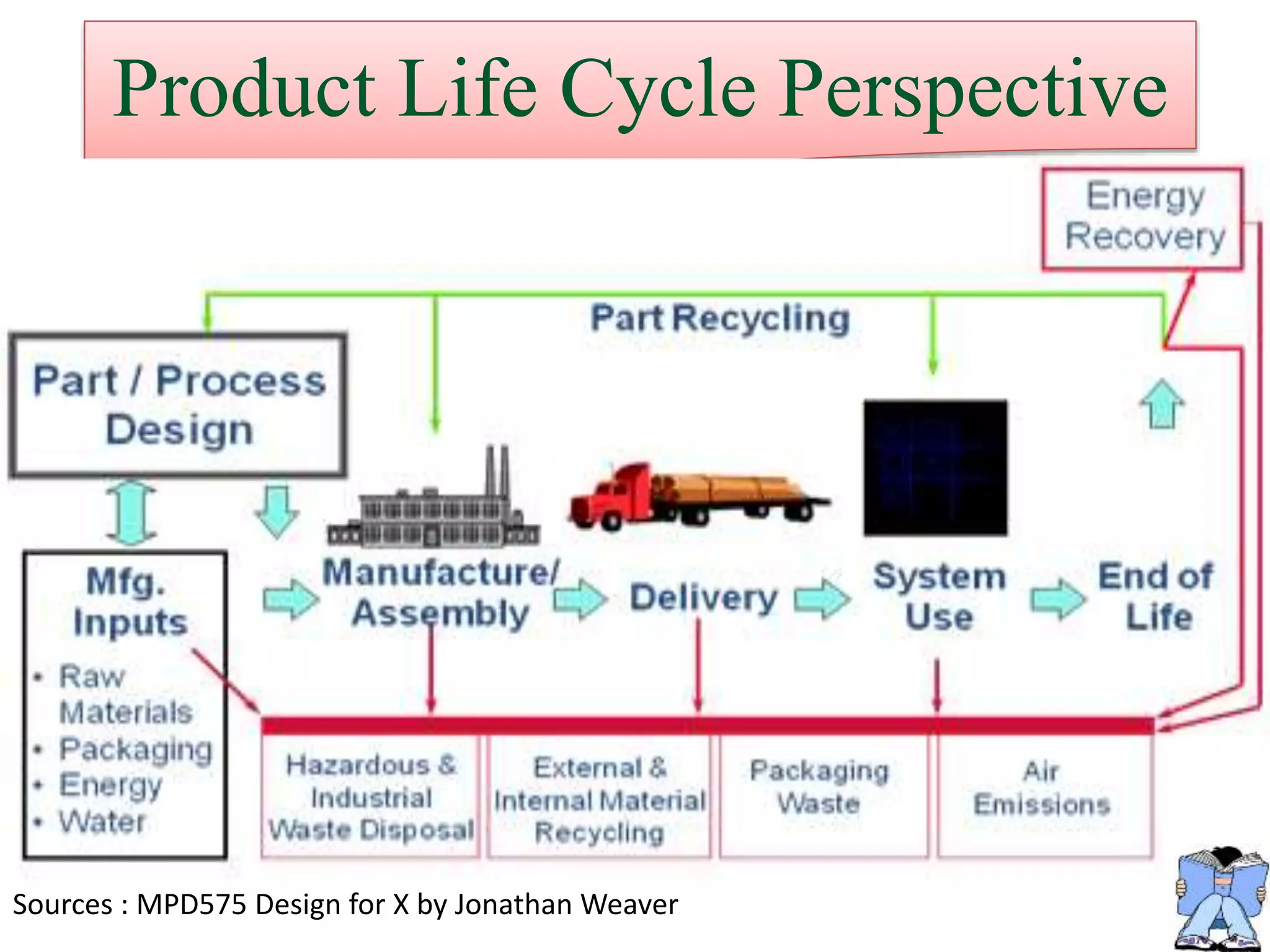

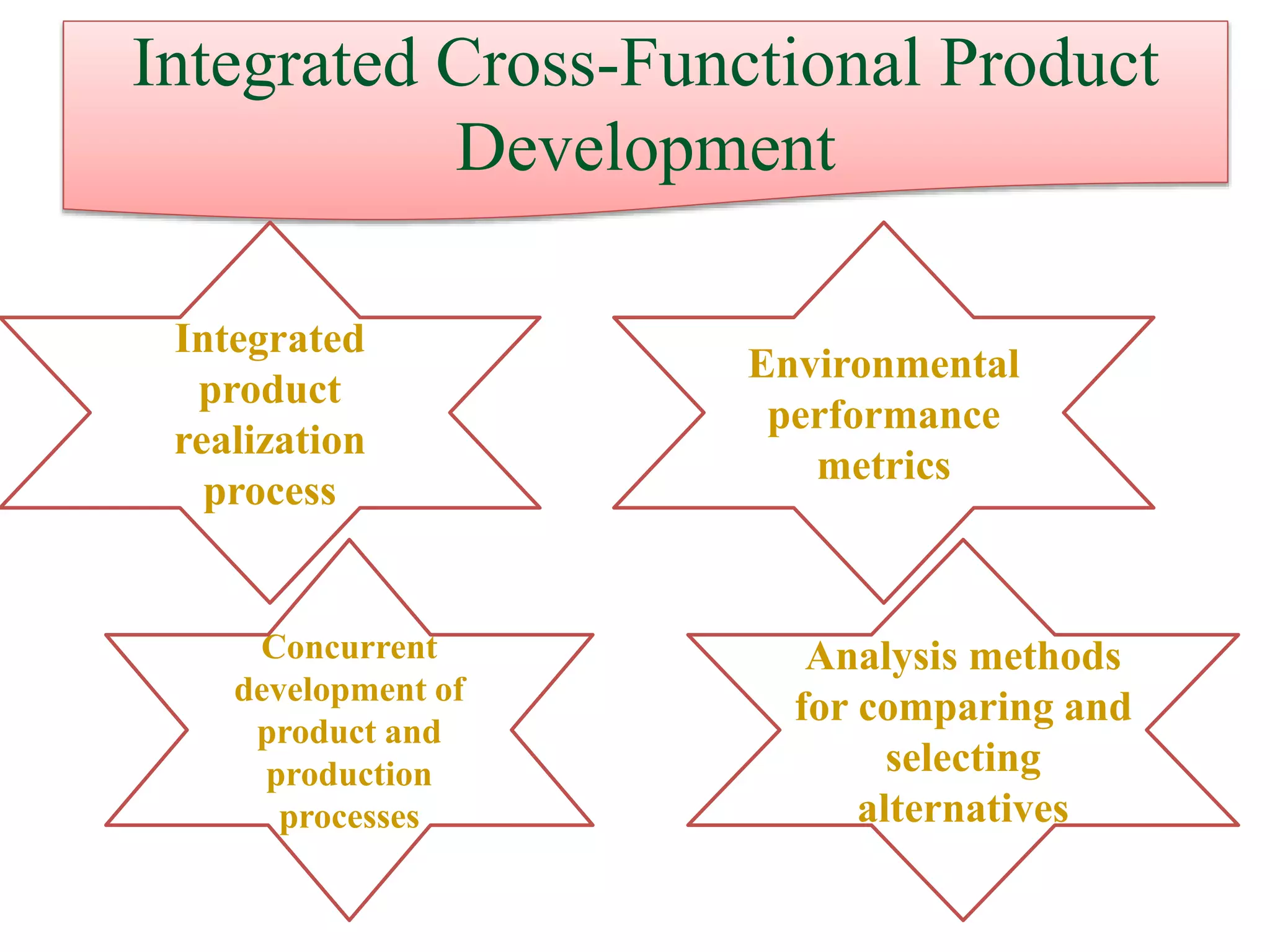

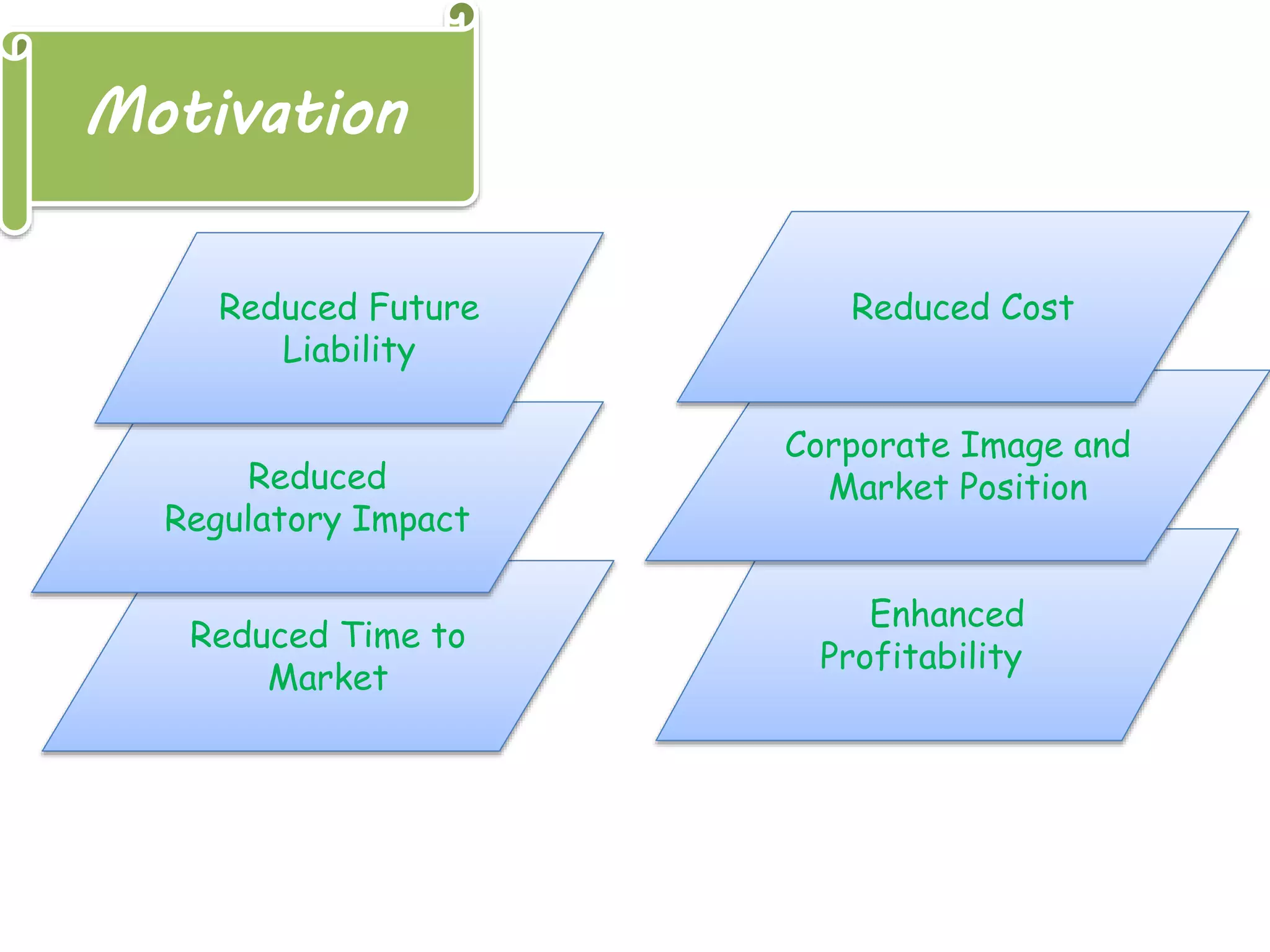

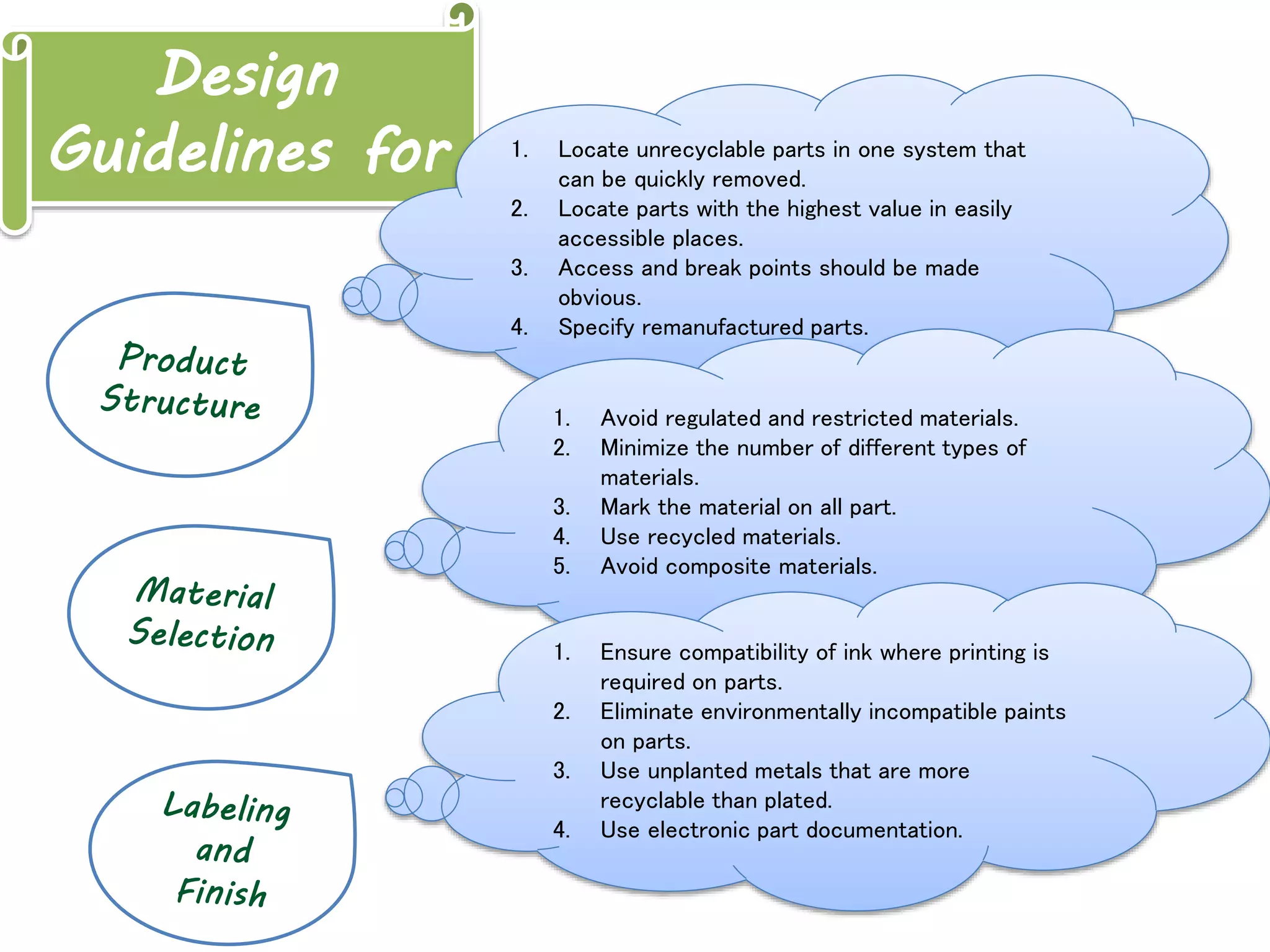

Design for Environment (DFE) is a systematic approach to evaluate the environmental impacts of products and processes over their full life cycles. The main goals of DFE are to promote safer products and define best practices to protect human health and the environment. Key principles of DFE include improving safety, health and environmental protection, using resources wisely, and incorporating environmental considerations into product design and technical management systems. DFE takes a product life cycle perspective and utilizes integrated cross-functional development. Successful DFE implementation can provide benefits like enhanced profitability, improved corporate image, and reduced costs and regulatory impacts.