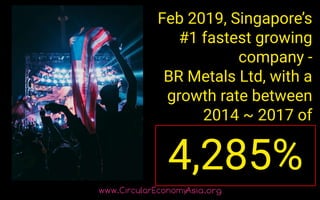

The document discusses the concept of a circular economy, emphasizing the transition from waste to resource by utilizing secondary raw materials and rethinking food waste. It highlights examples of companies creatively repurposing waste into valuable products while outlining the benefits of a circular design for sustainability and economic growth. It also presents opportunities for job creation in recycling and resource recovery, particularly in developing countries.