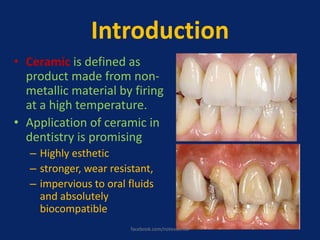

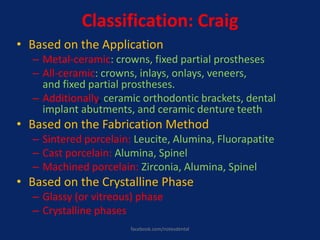

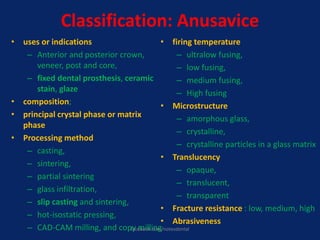

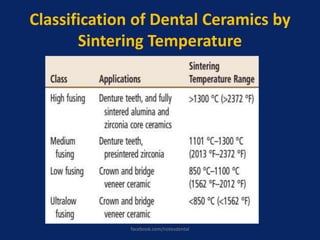

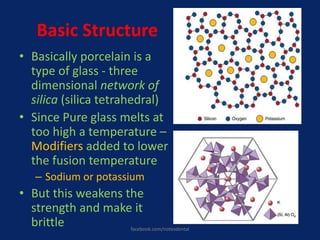

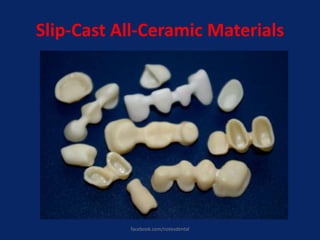

Ceramics have many applications in dentistry due to their esthetic qualities, strength, and biocompatibility. Ceramics are used in crowns, bridges, veneers, dentures, and more. There are several types of ceramics including metal-ceramics, which combine a ceramic material fused to a metal framework for strength, and all-ceramic options made of materials like alumina and zirconia. Ceramic materials are fabricated through processes like sintering, heat pressing, slip-casting, and CAD/CAM milling. Ceramics provide natural-looking and long-lasting restorations but also have limitations like brittleness which new materials continue to address