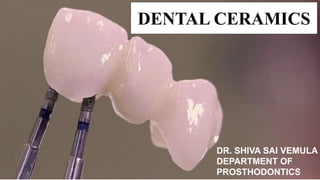

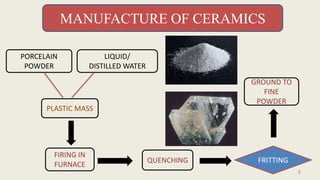

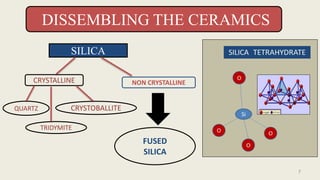

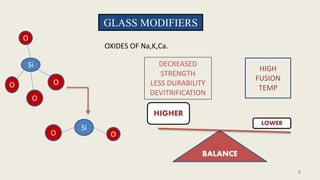

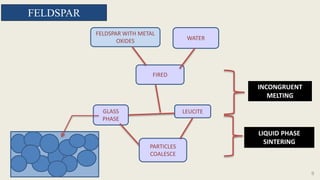

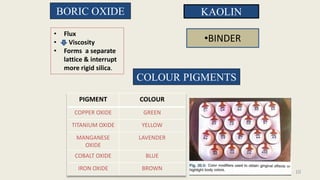

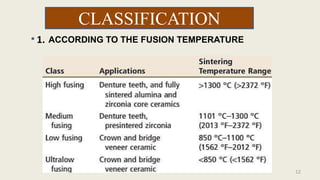

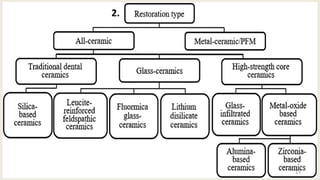

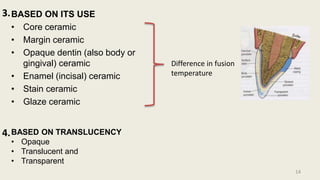

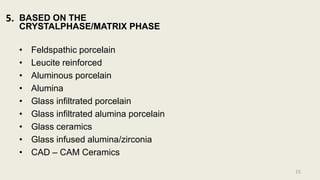

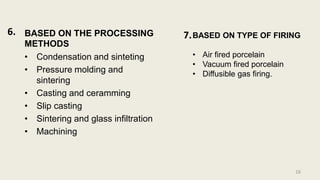

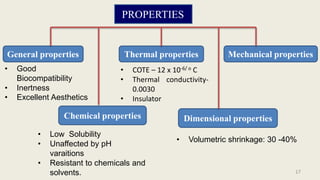

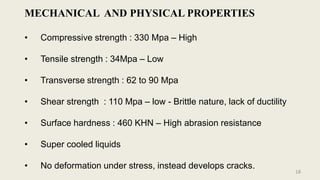

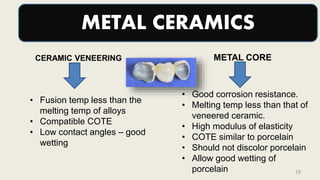

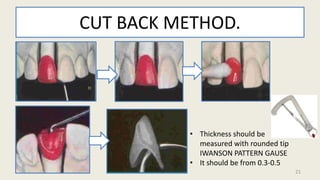

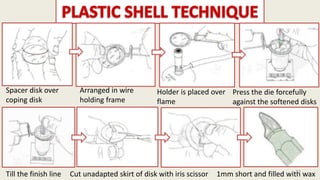

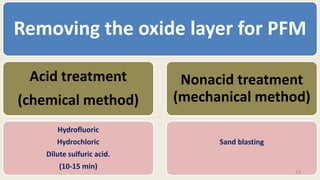

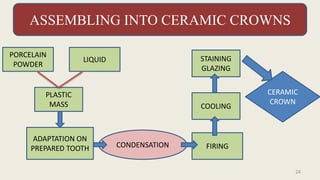

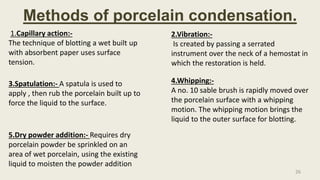

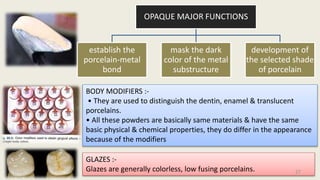

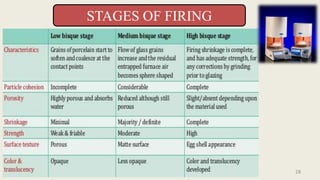

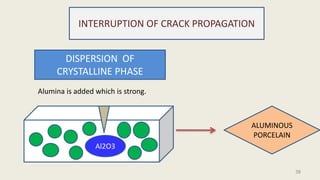

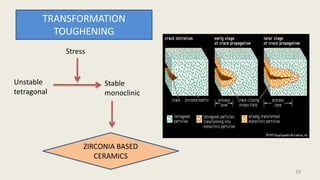

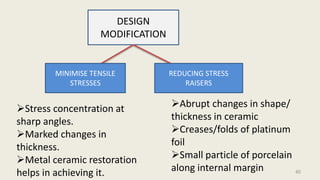

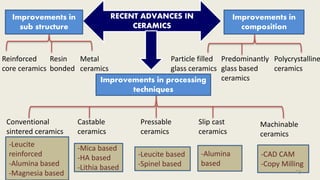

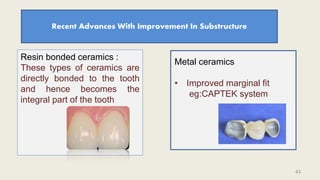

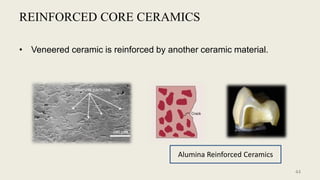

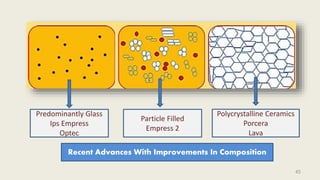

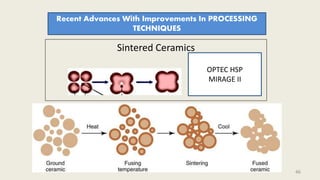

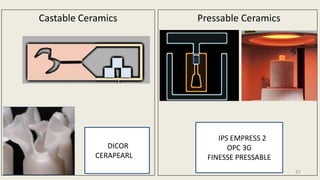

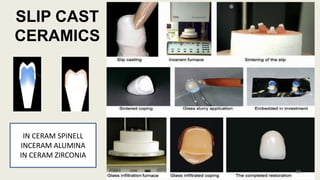

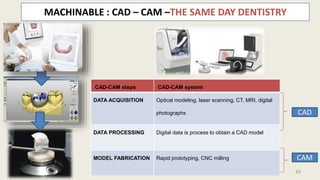

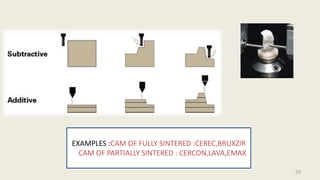

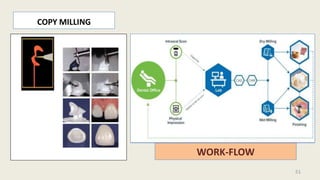

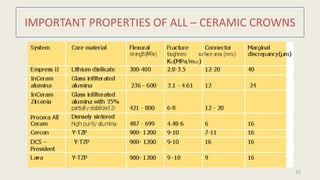

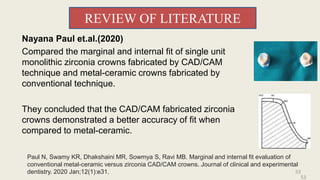

The document provides an extensive overview of dental ceramics, including their composition, manufacturing processes, classifications, properties, applications, and recent advancements in the field. It highlights the significance of ceramics in dental restorations due to their biocompatibility, strength, and aesthetic qualities. Additionally, the document discusses various methodologies for processing ceramics and the advancements in technology such as CAD-CAM techniques that improve the accuracy and fit of dental restorations.