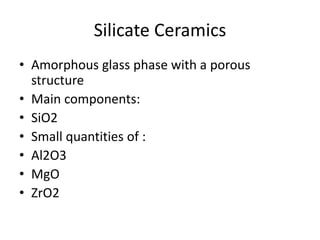

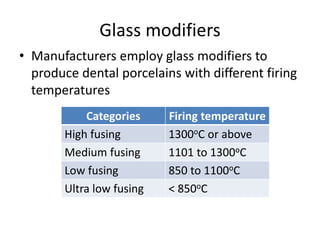

Ceramic materials are commonly used in dentistry. Ceramics can be classified into four main categories: silicate ceramics, oxide ceramics, nonoxide ceramics, and glass ceramics. Dental ceramics are typically composed of oxides and are formulated for use in dental prosthetics. Common dental ceramics include feldspathic porcelains, which are used in metal-ceramic crowns and bridges due to their esthetic properties and ability to fuse at low temperatures. All-ceramic crowns and veneers are also widely used for their superior esthetics compared to metal-ceramic options. Ceramics provide esthetic and durable prosthetic options but require careful