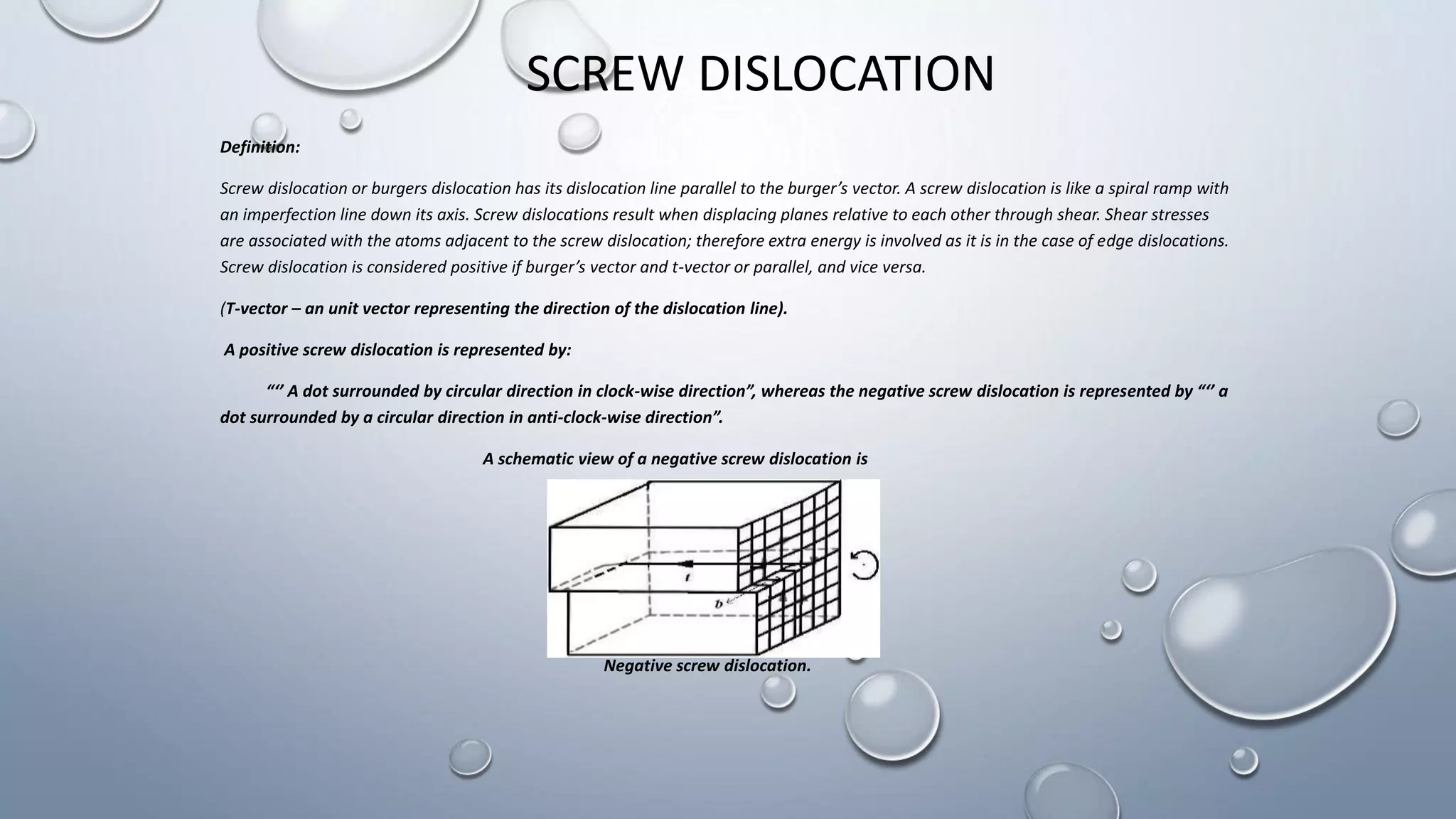

Line defects, also called dislocations, are disruptions in the regular ordering of atoms along a line in a solid. They are characterized by their Burgers vector. There are two main types of dislocations: edge dislocations, where the Burgers vector is perpendicular to the dislocation line, and screw dislocations, where the Burgers vector is parallel to the dislocation line. Dislocations influence the mechanical properties of materials and form during plastic deformation, solidification, and thermal stresses from rapid cooling. Real crystals contain a combination of edge and screw dislocations.