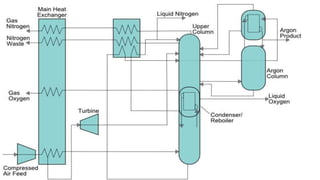

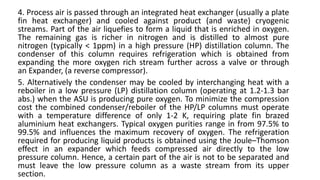

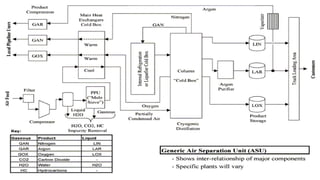

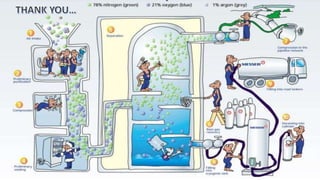

The document provides a comprehensive overview of air separation techniques, focusing primarily on cryogenic distillation, which is the most common method for obtaining high-purity nitrogen, oxygen, and argon from atmospheric air. It details the process of cooling and distilling air, emphasizing the energy-intensive nature of the operation and the need for advanced heat integration. Alternative methods, such as pressure swing adsorption and membrane technologies, are also mentioned, which can serve different applications including medical uses and aviation safety.