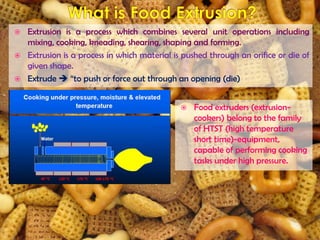

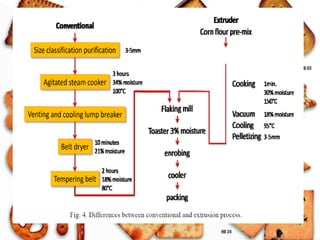

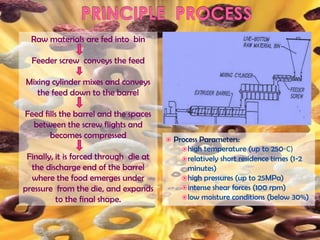

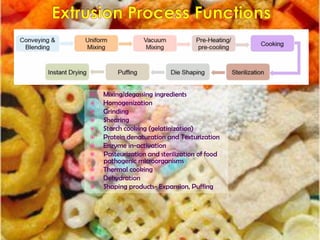

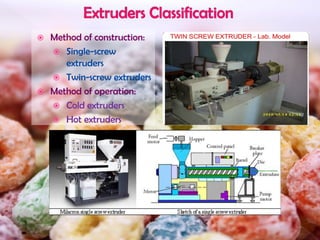

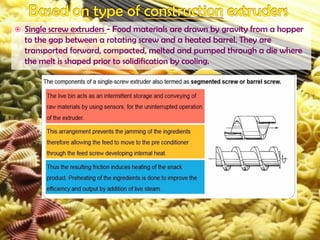

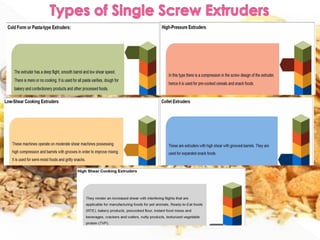

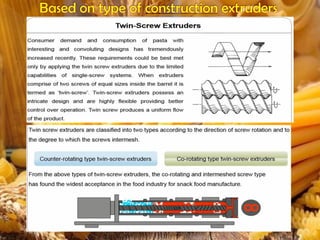

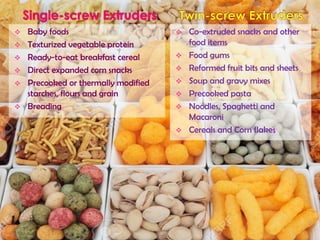

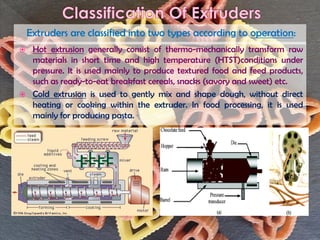

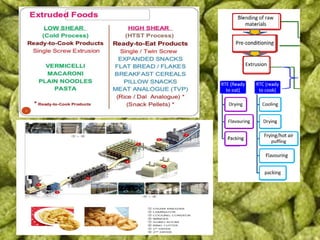

The document discusses the process of extrusion in food production. It begins with an introduction and overview of extrusion principles and equipment. Key points include that extrusion combines processes like mixing, cooking, and shaping using high temperature and pressure over short times. Extrusion forces material through a die to shape it. The document then provides details on extrusion applications in foods, advantages, parts of an extruder, and examples of common extruded foods. It concludes with some disadvantages of extrusion like color fading or nutrient loss due to the high temperatures used.

![ The samples were produced on the industrial production line.

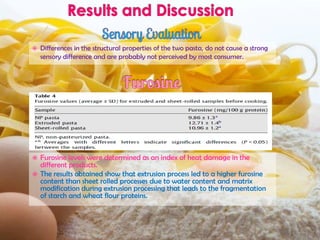

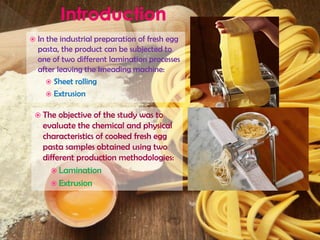

The fresh pasta was obtained by mixing durum wheat semolina (76% w/w; 12 ± 1%

w/w protein dry mass [dm]), pasteurized fresh egg (19% w/w), and water (5% w/w).

Its composition was: moisture 31.5 ± 0.5%; protein 13.29 ± 0.14%; ash 1.01 ± 0.007%; and

ether extract 3.76 ± 0.21%.

The pasta was formed into a sheet in one or other of the following processes.

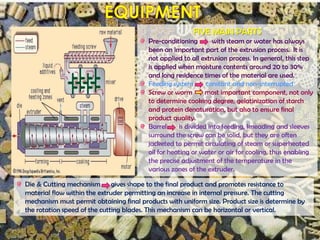

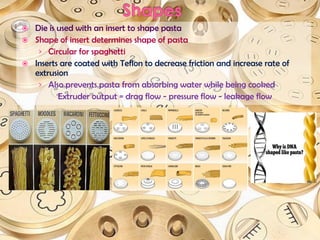

(1) Extrusion was by continuous press (model K500, Monferrato, Asti, Italy), with

a bronze die with circular punctures of 19 cm diameter and 2.5 cm breadth,

using a partial vacuum (300 mmHg). The sheets were passed through the press

until they reached the sheet-rolling stage, at the end of which the thickness of

the product was 0.90 mm.

(2) Lamination was performed where the pasta was rolled with four steel

cylinders to form a sheet of thickness 1 cm, then passed to a second cylinder (with

a cylinder diameter of 20 cm and rotation speed of 3.5 rpm), to produce a sheet

with a thickness of 0.90 mm.](https://image.slidesharecdn.com/janicelaforteza-extrusion-170710083415/85/Extrusion-Processing-by-Janice-Laforteza-33-320.jpg)