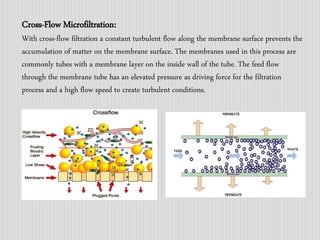

Microfiltration is a membrane solids separation technique used to remove particles and suspended solids from colloidal and suspended solutions with particle sizes ranging from 0.05-10 microns. There are two main types of microfiltration systems - cross flow microfiltration and dead end microfiltration. Microfiltration membranes are made from materials like ceramics, metals, and polymers and are commonly used to remove microorganisms, particulates, and reduce turbidity from water and other liquids.