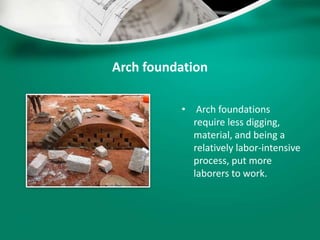

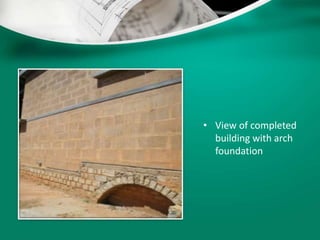

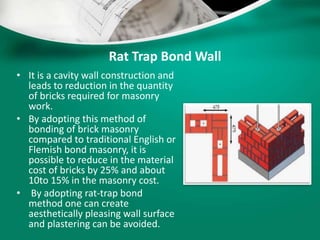

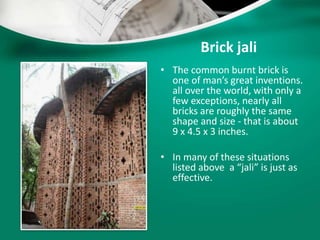

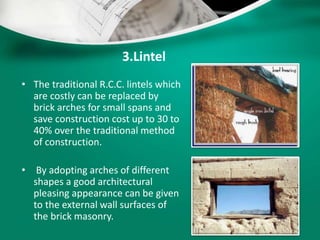

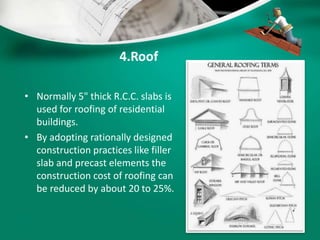

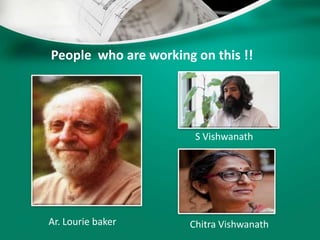

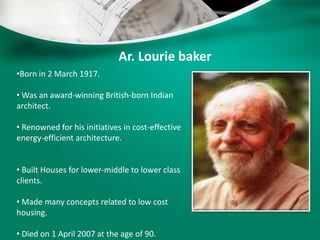

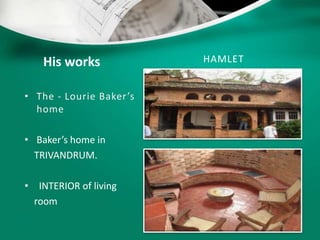

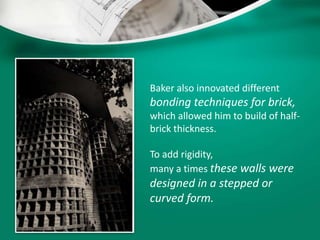

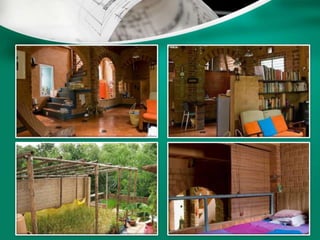

The document discusses low-cost housing construction techniques aimed at reducing costs while maintaining quality through the use of locally available materials and advanced technologies. Key methods include using arch foundations, rat-trap bond walls, and filler slabs, which together can significantly lower building expenses. Prominent figures in the field, like architect Laurie Baker, emphasized the importance of cost-effective and energy-efficient designs for various economic classes.